Exhaust gas heat exchanger

An exhaust gas heat exchanger , also known as AWT, is used to recover waste heat from exhaust gases from heating systems that are operated with wood , oil or other fuels . Flue gas heat exchangers are an essential component of condensing boilers .

In industrial furnaces , exhaust gas heat exchangers are used to separate water vapor and other condensable substances from the flue gas .

functionality

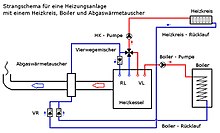

The use of a heat exchanger (heat exchanger) in the exhaust system of heating and industrial systems makes it possible to use the thermal energy of the exhaust gas, e.g. B. to increase the heating return temperature. This enables the energy consumption of the entire system to be reduced.

In heating systems, the exhaust gas is first passed through a register before it enters the chimney in order to feed part of the thermal energy back into the heating circuit.

Condensing technology

The great advantage of condensing heating is the additional use of thermal energy in the flue gases. The heating gases produced by the combustion are passed through the heat exchanger and heat the heating water, which flows through the AWT in the opposite direction of the exhaust gas. The cold heating water, which previously gave off its heat via the underfloor heating or radiators , takes the heat from the heating gases. This strong cooling of the gases leads to condensation and the release of heat, which is also transferred to the heating water.

Technical guide

The AWT is installed between the boiler and the chimney . The hot flue gases are cooled from 120 to 1200 ° C to 30 to 60 ° C. The thermal energy gained in this way is transferred to the heating or service water . This cooling causes the water vapor to condense (in the case of crude oil from 47 ° C, in the case of natural gas from 57 ° C), which also significantly improves the heat transfer from exhaust gas to water. At the same time, various pollutants are washed out of the flue gas. In accordance with regulations, the condensate is normally discharged into the sewer system directly or via a neutralization box. The compact design of the AWT allows it to be retrofitted in practically any heating system.

Condensation = low flue gas temperatures

The AWT cools the exhaust gases and transfers their energy (mostly through water) into a heating circuit. In order to obtain as large an area as possible, which is heated by the exhaust gas, the tubes for energy dissipation are usually led across the exhaust gas pipe.

Per liter of condensing water, a maximum of 0.67 kWh (condensation heat) can be added to the water circuit of the central heating. In practice, the exhaust gases in the condenser are cooled by the heating return; In order to condense as large a proportion of the combustion water as possible, low return temperatures should therefore be aimed for. However, the cooled exhaust gases usually no longer rise independently in the chimney, which makes a forced draft burner or an exhaust fan necessary. Additional condensation can occur in the chimney.