chimney

A chimney is a predominantly vertical flue gas pipe in or on buildings or systems , on ships or on steam locomotives , which discharges flue gases into the open. The part of a house chimney that protrudes above the roof surface is called the chimney head . An inclined guided chimney is as warped , abducted or as tow forge designated.

In the past, resistance to soot fire was crucial for the design of the chimney. Exhaust gas does not contain any soot components , so that there is no need for soot fire resistance in the case of a pure exhaust pipe. In modern exhaust systems, due to the formation of condensate due to low exhaust gas quantities and temperatures, acid and moisture resistance are the main factors.

Industrial chimneys are sometimes called chimneys . In buildings, the chimney is also called Esse in East Central German , in Austria and South Germany the chimney or “the chimney ”, and in Switzerland mostly “the chimney”. Fireplaces can be misunderstood, as fireplaces with a visible flame built into a wall are also called a fireplace . Colloquially, cooling towers and other towers, such as the hot-air chimneys of updraft power plants , are also called chimneys.

The flue gas pipe within a fireplace is called a draft , with a new draft beginning at each deflection of the flue gases.

Terminology

According to DIN 18160-1, a chimney serves to discharge combustion gases from fireplaces into the open air and to produce the negative pressure required to suck in the combustion air. It is part of an exhaust system or an exhaust system in the broader sense.

The innermost channel of multi-layered chimneys, which comes into contact with the flue gases, is called the smoke pipe . The flue pipe running horizontally or diagonally from the stove to the chimney is referred to in the guidelines as a connector and colloquially as a stove pipe .

Chimneys in traditional style are propagated by exhaust pipes ( exhaust pipe replaced) by which indeed exhaust, but no flue gas can be routed because this addition to liquid water in accordance with DIN EN 1443 (mist droplets) and soot must not contain, which to a chimney fire can result.

etymology

The origin of the word can be proven in terms of linguistic history as follows: ahd. Scorrenstein , Middle High German schor- , schorn- , schürstein . The first part of the compound is occupied by mnd. schor (e) and the verb ahd. scorren (" upright ") mhd. schorren ("abruptly protruding "). The chimney is thus probably originally the supporting stone on which the smoke outlet rises. However, it was already used in the past to mean “fireplace, stove, stove”.

Regional names

In other language areas than North German, the terms Rauchfang , Esse , Kamin or Schlot are used . Today chimney is the leading variant in Germany, which is increasingly replacing the other terms.

House chimneys

function

The function of the chimney is based on the chimney effect . It creates a lift due to the gas column, which is lighter than the surrounding air . The geometric parameters of height and clearance of the chimney must therefore be matched to the amount of gas to be pumped and its temperature .

The flow of the gas generated by the Bernoulli effect in the chimney a lower air pressure , which prevents fumes penetrate from furnaces in the living areas. The design must be such that the wind cannot push into the chimney (it must be in the free wind flow). In order to prevent warm air from being continuously withdrawn from the stove or the rooms in which it is located, even outside the firing phases, a flue gas damper must be installed or the air supply to an airtight stove must be blocked in some other way.

Since modern with fans powered ventilation in the bathroom and range hoods in the kitchen surpass the delivery pressure of a chimney by far, they could due to incomplete combustion nascent carbon monoxide pull backwards through the oven in the room and and exhaust carbon monoxide poisoning cause. For this reason, in apartments with fan ventilation, a stove or chimney may only be operated with a corresponding supply air duct. The supply air shaft should in turn be closable for breaks in operation in order to prevent the warm air from being drawn off.

Modern domestic hot water heating systems with low temperature and condensing technology no longer have sufficiently high flue gas temperatures to avoid condensation when operating the chimney . The exhaust gases reach their dew point inside the chimney and condense on the wall. This must then be made moisture-resistant from a resistant material such as ceramic or stainless steel in order to avoid sooting . If the flue gas temperatures are so low that there is no sufficient lift, a fan ("flue gas fan", " induced draft fan ") is used to convey the gases through overpressure or underpressure, which affects the design of the combustion chamber and / or the "flue gas pipe" “Has (required gas tightness).

Because of its safety function in domestic fireplaces, the chimney, like the exhaust pipe, is subject to building regulations. The acceptance and inspection is carried out in Germany by the chimney sweep .

Transmitter mast disguised as a chimney

execution

The internal free diameter of the smoke pipe or chimney is typically 12 to 14 cm for oil, gas and pellet heating systems, 16 to 18 cm for fireplace and tiled stoves and at least 20 cm for open chimneys .

DIN V 18160-1: 2006-01 contains the necessary distances to flammable building materials to avoid ignition, even in the event of a soot fire . Chimney constructions are assigned a soot fire resistance class. Class G50, for example, identifies a construction that is sootfire-resistant up to a distance of 50 mm. The necessary distances to wooden beams can also be found in the firing regulations of the German federal states. If the joint to combustible building materials cannot be kept open, good ventilation is required. Backfilling with non-combustible insulation material is permitted in special cases. Narrow components such as strips or slats that are only slightly in contact with the chimney do not have to keep a gap. As a rule, a distance of at least 20 cm must be maintained to windows. The manufacturers of thermal insulation glazing often require a greater distance to prevent the glass from bursting due to thermal stresses . Exposed flue pipes must be kept at a distance of 20 cm from flammable components, unless they are covered by a covering of non-flammable insulating material at least 2 cm thick or the flue gas temperature of the fireplace cannot reach a maximum of 160 ° C.

Types

The following house chimneys are common in Europe:

- three-shell chimneys consist of a shaft (casing brick) or outer pipe, insulation and inner pipe

- Double-shell chimneys consist of a shaft or an outer pipe with an inner pipe

- Single-shell chimneys consist of a shaft made mostly of mineral building materials

Double-walled chimneys made of stainless steel are available in two-shell or three-shell designs if there is still an insulation layer between the inner and outer pipes.

The exhaust heat is retained by an insulating layer, which increases the negative pressure and there is no risk of ice forming at the chimney mouth. Insulation is usually only necessary if the exhaust system is routed outside the building.

Double-shell chimneys are often used as exhaust pipes or where exhaust gases are discharged under excess pressure.

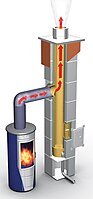

Room air-independent heating devices are often connected to a double-shell chimney, in which the space between the shaft or the outer pipe and the inner pipe is used to supply combustion air. These chimney systems are also called LAS chimneys .

Section through a double-shell LAS chimney

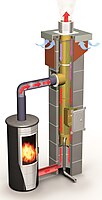

Section through a three-shell LAS chimney with flue gas and air intake

Section through a three-shell W3G LAS chimney

Recently, because of the Energy Saving Ordinance (EnEV) for stoves and chimneys, air-independent devices have also been on the market; these are then connected to three-shell LAS chimneys. The stove then draws its combustion air from the outside through the air supply shaft of the chimney, instead of taking it from the installation room like normal stoves. This enables the building envelope to be made airtight, as required by the EnEV.

In order to save energy, the flue gas temperature of the fireplace is getting lower and lower, which can lead to the chimney falling below the dew point temperature even with solid fuels such as logs and wood pellets . This creates condensate , which is why a new type of chimney is required for these fireplaces. This type should have the classification "W3 Gxx", such a system is commonly referred to as "W3G chimney". These systems are insensitive to moisture even after a soot fire ( chimney fire ).

The Russian chimney is a special type of chimney. It is characterized by a narrow cross-section. This design based on the Russian model has been common in Germany since the end of the 19th century . The older chimney construction method in Germany has a larger cross-section and can be climbed by the chimney sweep.

history

The chimney was developed by the ancient Romans in the form of the hypocaust , but was forgotten again. It did not reappear until the 10th - 11th centuries, before there were only single-storey one-room houses (from which, among other things, hallway houses developed). The smoke moved from the stove through the whole house and escaped through openings in the roof. This meant that the whole house was heated, but also that the soot was deposited in the cooking area ("Rauchkuchl") and in the whole house (including clothing, lungs and skin of the residents) and the risk of fire increased. Meat and fish were hung near the stove or under the roof to protect them from rodents or pets and were automatically dried and smoked there . With the introduction of the mezzanine ceilings, there was a need for better smoke extraction.

There was a funnel-shaped chimney above the open fire, which opened into the chimney at the top and in which sausage and meat could also be smoked. With the advent of brick or iron stoves , the chimney became superfluous, and in rural areas cooking over an open fire continued until the end of the 19th century. The house's stoves in other rooms that are used purely for heating purposes have already been connected directly to the chimney beforehand.

Through regular array on the roof surface and technically elaborate design chimneys were, for example, in the palace of the Baroque period used as an architectural decorative element. Here, a so-called warping of the chimneys was often necessary, ie the smoke channel was guided almost horizontally below the roof surface so that it could emerge from the roof at the aesthetically correct point; sometimes even additional dummy chimneys were added to maintain the regular structure. In terms of monument preservation , it is problematic that chimneys that are no longer required are often broken off when roofs are replaced and their aesthetic function is lost as a result.

Orders from Count Palatine Karl IV. From 1772 also served to prevent a fire in connection with domestic fireplaces. According to the simultaneous building regulations, no more wooden chimneys were allowed to be erected, no more wooden hoses were allowed to be installed, which had to lead the smoke from the fireplace to the fireplace, just as it was forbidden to lead stovepipes out of the window.

Chimneys in power plants and industrial applications

The first high factory chimneys go back to the beginning of industrialization and are a further development of the experiences made with blast furnaces . They were walled up from very hot, therefore very hard bricks, some of which were also clad with refractory materials. The chimneys served, on the one hand, to improve the extraction of the fireplaces (see chimney ) and, on the other, to keep the air clean . Therefore, they were always built much higher than the surrounding buildings - which on the other hand brought a stronger attack of the wind with it.

Construction

In particular, power station and industrial chimneys are dimensioned in height so that they emit the mostly environmentally harmful exhaust gases at a height where the winds blow much more strongly than near the ground and where they mix with (while they sometimes sink towards the ground) strongly dilute clean air. Sometimes their height is measured by the fact that they pierce a possibly existing inversion layer.

They are usually designed with two shells:

- An outer shell made of concrete or masonry that serves as a supporting structure for the loads on the chimney

- An inner shell that carries the smoke gases and is made of a material that is chemically resistant to acid attack

The exit speed of the flue gas from the chimney head is up to 20 meters per second in coal-fired power plants .

High chimneys are equipped with air traffic control lights and in many countries (but only rarely in Germany) they also have a red and white warning paint on the upper part for the same purpose during the day.

Installation of the now blown 300-meter chimney in the Thierbach power plant

Industrial chimney of a thermal power plant in Zurich

Chimney of the Ekibastus power plant in Kazakhstan

Steel chimney with Scruton helix against resonance vibrations

Cooling towers as chimneys

Cooling towers can also be used as chimneys. This process is called clean gas discharge . With this method, the flue gas is led into the center of the cooling tower at about a third of the cooling tower height (above the irrigation level) and released into the steam plumes there.

In coal-fired power plants with a clean gas inlet, the desulphurized flue gases cleaned by electrostatic precipitators are discharged via the cooling tower . For this purpose, the flue gas pipe is led above the irrigation level into the middle of the cooling tower. In systems without flue gas cleaning (especially flue gas desulfurization), however, severe corrosion would occur in the cooling tower .

Weisweiler power plant : red flue gas pipes guide the exhaust gases into the cooling towers after conversion

The advantage of this technology, which was first used in Germany in 1982 in the Völklingen model power plant (clean gas discharge), is that the heated and humid exhaust air from the cooling tower offers significantly more buoyancy than the flue gas. This means that the exhaust plume can be distributed with a lower overall height than with a “conventional” chimney. This is particularly advantageous in coal-fired power plants , because the exhaust gases after being washed wet in the flue gas desulphurisation system (FGD) are greatly cooled and only have a low level of buoyancy.

The disadvantages of this technology include the disproportionately large dimensions of the combined cooling tower, the minimum height achieved is 100 m ( Völklingen model power plant, built in 1982 ), but in recent years only towers between 155 m and 200 m high have been built around one to achieve higher cooling performance. Especially in the case of adjacent residential developments, such as in the cities of Datteln and Duisburg-Walsum , the new blocks with the combined cooling towers for smoke evacuation were built as a new block on existing systems. In some cases, there was previously no cooling tower at these old locations, as the heat was dissipated differently (for example, through-flow cooling via adjacent bodies of water); the flue gas was discharged through conventional chimneys. Now, at these locations, the tower and the steam plumes generated during operation have undesirable effects on the microclimate , for example locally increased amounts of precipitation and extensive shading.

In order to avoid these disadvantages, planning changes were made after public protests. At the coal-fired power station Moorburg in Hamburg , for example, the original planning of a natural draft cooling tower with combined use as a chimney was changed. The implemented planning includes a low hybrid cooling tower (height 65 m). Due to the complex flue gas cleaning, a very high chimney can be dispensed with. The new conventional chimney has a height of 130 m.

| Tower height | Power plants with cooling towers as chimneys | fuel |

|---|---|---|

| 100 m | Völklingen / Fenne power plant (HKV & MKV blocks) | Hard coal |

| 110 m | Frimmersdorf power plant (Block Q) | Brown coal |

| 120 m | Jänschwalde power plant (Blocks A – F) | Brown coal |

| 128 m | Niederaussem power plant (units G & H) | Brown coal |

| 135 m | Quiersche / Weiher power plant (Weiher III block) | Hard coal |

| 141 m | Black Pump Power Plant (Units A & B) | Brown coal |

| 141 m | Staudinger power plant (block 5) | Hard coal |

| 141.5 m | Rostock power plant (monoblock power plant) | Hard coal |

| 155 m | Boxberg power plant (Block R) | Brown coal |

| 160 m | Lünen power plant (Lünen-Stummhafen block) | Hard coal |

| 165 m | Westphalia power plant (blocks D & E) | Hard coal |

| 172 m | Neurath power plant (Blocks F & G) | Brown coal |

| 174.5 m | Lippendorf power plant (R & S blocks) | Brown coal |

| 180 m | Datteln power plant (block 4) | Hard coal |

| 181 m | Duisburg-Walsum power plant (Block 10) | Hard coal |

| 200 m | Niederaussem power plant (Block K) | Brown coal |

Tallest chimneys

The tallest chimney in the world is the chimney of the Ekibastus power plant in Ekibastus , Kazakhstan . It is 419.7 meters high. One of the tallest chimneys in the western world is the 381 meter high Inco Superstack from a nickel smelter in Greater Sudbury , Ontario , Canada . Europe's tallest chimney is the 360-meter high chimney from Trbovlje in Slovenia .

The tallest chimney ever built in Germany is the 307 meter high chimney of the Buschhaus power plant near Helmstedt .

The highest brick chimney with approx. 140 m is the Halsbrücker Esse near Freiberg . Concrete chimneys are built with bricks from a construction height of 200 meters. Because of the increased corrosion caused by the weather, repair measures on the corroded parts can then be carried out more cost-effectively (new construction through partial demolition). B. Copper works in Duisburg in North Rhine-Westphalia.

Chimneys on ships

With the introduction of steam engines to drive ships , chimneys were also built on the deck of these vehicles. If these were initially used to remove smoke and exhaust steam, they soon became a recognition signal for the shipping company concerned . In the time of the fast steamers , the number of chimneys became a status symbol . For example, some shipping companies had two or three active chimneys built as a dummy . The rear chimney at the Cap Arcona was only an ornament. But there were also ships with more than four funnels.

There were several approaches to preventing smoke and debris from falling out of the chimneys onto passenger decks:

- ship chimneys as high as possible

- small wing stubs to create a wake vortex that directs the smoke gases in a horizontal direction (e.g. Norway )

- attached horizontal disc (e.g. on the Maxim Gorkiy ).

River ships often had folding chimneys so that they could also pass low bridges.

Chimneys of steam locomotives

The chimney of a steam locomotive is slightly conical and made of cast iron . It rests on the smoke chamber jacket with a cast flange and protrudes deep into the smoke chamber . At the bottom it is provided with a collar that favors the extraction of the smoke gases.

legislation

The first measures against air pollution were taken in antiquity and often consisted of relocating businesses with strong odors or smoke (e.g. tanners or glassmakers ) to the suburbs of cities.

There were isolated legal restrictions on pollutant emissions from the late Middle Ages for metallurgy and especially smelters , e.g. B. in Cologne 1464, and later in craft centers such as Nuremberg and Augsburg. Soon after the start of industrialization, many factories - for example in the Central English Black Country - either voluntarily went to the outskirts or built ever taller chimneys. The highest factory chimney in Central Europe was built by the Lenzing AG pulp factory around 1950 due to the conditions imposed by the Upper Austrian government .

However, clearer legal framework conditions were often only adopted after environmental disasters . Probably the worst smog poisoning in industrial history happened from December 5th to 9th, 1952 in London (see smog catastrophe in London 1952 ). Sulfur gases and soot from factories and house fires collected on the ground and mixed with car exhaust. The poisonous air mixture became so dense in places that you could no longer see your feet on the street, and killed around 10,000 people. This catastrophe was the reason for the "Clean Air Act" against extreme air pollution passed in 1956. Among other things, he restricted open chimneys and, among other measures, also prescribed heights of the pit.

Today, on the other hand, emissions are more likely to be limited by limit values, because better measurement methods for environmental monitoring have also been developed. Thanks to extensive exhaust gas cleaning , many companies no longer need tall chimneys, so that they are torn down or occasionally rededicated as industrial monuments.

Special functions of large chimneys

Landscape feature

During the founding period , factory chimneys were often placed in such a way that they gave the respective city district a certain character. Wealthy industrialists attached great importance to the artistic design of the factory walls, portals and chimneys - for example through the z. B. in Thuringia widespread jewelry technology with offset bricks.

Survey point

For geodesy - which usually lacks a clear view, especially in industrial areas - symmetrically bricked factory chimneys were often measured as high points , as they are well suited as fixed points . In contrast to church towers or masts, however, they require double aiming, which the geodesist calls “vent left, vent right”. The direction is determined by forming the mean . The lightning rod attached to the top of the chimney is only used as a target in isolated cases because it can change due to the weather .

Support for antennas

Some large chimneys also have transmission antennas for low-power (transmission power <1 kW) VHF radio or television stations. They are also popular as carriers of cellular antennas. However, the smoke gases can cause corrosion problems.

Others

Large chimneys can also serve as a water tower by means of a chimney container .

Some chimneys of several large power plants in the former Soviet Union are equipped with outriggers where the conductors of the power plant outgoing lines are passed over the power plant building. However, this variant was only rarely implemented due to possible corrosion problems.

The chimney of the Pei Tou waste incineration plant carries a revolving restaurant.

Use of closed chimneys

Decommissioned industrial chimneys can e.g. B. can be converted into transmission towers. One example of this is in Leipzig-Connewitz . In addition, they are often used advertising media because of their often towering height.

In Weißandt-Gölzau , a chimney was converted into a wind turbine.

Art on chimneys

Some house and, above all, factory owners had the chimneys artistically designed or clad with tiles . Today some of these works of art or particularly beautifully masonry specimens are dedicated as industrial monuments or embedded in a total work of art. The artistically elaborate chimneys by Antoni Gaudí in Barcelona are outstanding .

See also

Web links

- Chimneys at structurae.de

- Chimney systems with solid outer shells BauWissen Online

Historical

- Chimney . In: Heinrich August Pierer , Julius Löbe (Hrsg.): Universal Lexicon of the Present and the Past . 4th edition. tape 15 . Altenburg 1862, p. 394-396 ( zeno.org ).

- Chimney article from Lueger, Otto: Lexicon of the entire technology and its auxiliary sciences, Vol. 7, Stuttgart, Leipzig 1909, pp. 775 - 781 .

- Industrial history documents from the industrial district in Lower Austria

Individual evidence

- ↑ a b c Dipl.-Ing. Wolfgang Wegener: Chimney technology ... and the responsibility of the planner , p. 3, Initiative pro Schornstein eV; accessed in November 2019

- ↑ Text of DIN 18160 on www.Ofseite.de; accessed in February 2017

- ↑ Information on exhaust systems , Bruno Bosy

- ^ "Third round - chimney / fireplace" , Atlas on German everyday language (AdA), Phil.-Hist. Faculty, University of Augsburg, June 19, 2006

- ↑ Information and guidelines on chimneys and flue gas routing , company KLB; accessed in February 2017

- ↑ Article Schornstein in Meyers Konversations-Lexikon, 1888. Quotation: “As a rule, it is permitted to use the closest, so-called Russian smoke tubes of 16 cm, which should be further 21-26 cm in a square or better in diameter, if they are used for closed (covered) firing (for room stoves, for so-called economy stoves and most technical firing systems).

- ^ History of the chimney sweep . private website

- ^ Franz-Josef Sehr : The fire extinguishing system in Obertiefenbach from earlier times . In: Yearbook for the Limburg-Weilburg district 1994 . The district committee of the Limburg-Weilburg district, Limburg-Weilburg 1993, p. 151-153 .

- ↑ Völklingen / Fenne power plant at power-saar.steag-saarenergie.de .

- ↑ Power plant Moorburg technical details on vattenfall.de .

- ↑ Atominfo.ru: projects that reduce construction costs are classified as hostile by contractors: director of ОАО СПбАЭП

- ↑ Report: “Ship chimneys through the ages”, magazine stander, issue 6, 1980