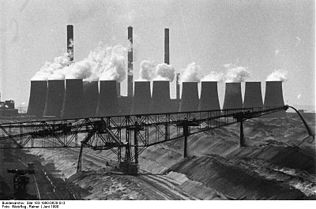

Boxberg power plant

| Boxberg power plant | |||

|---|---|---|---|

| Boxberg power plant (2012), view from the Lausitz boulder park Nochten : (from left to right) Block R, Block Q, cooling tower Block R, cooling tower Block Q (behind the last chimney, which has since been blown up), Plant 3 | |||

| location | |||

|

|

|||

| Coordinates | 51 ° 25 '7 " N , 14 ° 34' 6" E | ||

| country | Germany | ||

| Waters | Surrounding waters and groundwater from the nearby opencast mines | ||

| Data | |||

| Type | Thermal power plant | ||

| Primary energy | Brown coal | ||

| fuel | Brown coal | ||

| power | 2575 MW | ||

| operator | Lausitz Energie Kraftwerke AG ( LEAG ) | ||

| Project start | 1970s | ||

| Start of operations | Plant III (2 × 500 MW) 1978–1979 Plant IV (900 MW) 2000 Unit R (675 MW) 2012 |

||

| turbine | four- and five-casing condensing turbine | ||

| boiler | 4 × 815 tons of steam / h + 1 × 2422 tons of steam / h | ||

| Firing | Brown coal dust | ||

| was standing | October 19, 2009 | ||

The Boxberg power plant is a German lignite power plant in Boxberg / OL in Upper Lusatia ( Saxony ) in the Lusatian lignite district . During its highest expansion stage in the 1980s, it was the largest coal-fired power plant in the GDR with a nominal output of 3520 megawatts .

The power plant operated by Lausitz Energie Kraftwerke AG ( LEAG ) has a nominal output of 2575 megawatts.

Structure and technical data

The total nominal output is distributed over four power plant blocks . Plant 3 with its two 500 MW units was modernized from 1993 to 1995 and retrofitted, among other things, with a flue gas desulphurisation system . Plant 4 (Block Q) with an output of 900 MW (through upgrading up to 907 MW) was built from 1996 to 2000 and has been feeding electricity into the network since 2000 . Unit R has an output of 675 MW, which has been fed in since autumn 2012.

The efficiency of the older system is around 36%, while the newly built system is approximately 42% efficient. The systems are also cooled separately: While Plant 3 is cooled by three cooling towers , the two newer blocks each have only one, but much more powerful cooling tower. Part of the heat generated during power generation is decoupled from the process and used for district heating at the location, for the municipality of Boxberg and for the city of Weißwasser .

The power plant's daily lignite consumption is up to 50,000 tons. Most of the coal comes from the nearby Nochten and Reichwalde open- cast lignite mines , where it is extracted from a 12-meter-thick seam that is 65 to a maximum of 100 meters deep. The annual output is around 17 million tons of raw brown coal.

The grid connection is made via the Bärwalde switchgear at the 380 kV maximum voltage level in the 50Hertz Transmission grid .

history

The first power plant at the Boxberg location was built in 1966 by VEB BMK Coal and Energy . At the beginning of the 1980s, 14 power plant units with an installed capacity of 3520 MW were already in operation (12 × 210 MW + 2 × 500 MW). At that time, Boxberg was the largest power plant in the GDR, along with the Greifswald nuclear power plant, and the largest European power plant based on lignite and provided employment for 4,600 people.

After the reunification of Germany, most of the power plant units were shut down due to the filter technology and efficiency that did not meet the German requirements. The old systems of the Boxberg power plant are still being dismantled today. The two plants 1 and 2 with a total of twelve units with 210 MW each were shut down in the period from 1993 to 1998. On April 13, 2006, four of the nine unused cooling towers of the old plant were blown up.

Chimney collapse in 1984

In 1984 the 150 m high reinforced concrete chimney "Interim Chimney B", which was only put into operation in 1983, collapsed completely. Above the flue gas inlet, there was a break at a height of about 40 m due to the insufficient strength of the concrete after the chimney had been excited to vibrate by gusts of wind in the slipstream of a 300 m chimney.

Accident in January 1987

In the winter of 1986/1987, large parts of the GDR were extremely cold, which on the one hand resulted in an increased demand for coal and electricity and, on the other hand, resulted in problems with the charging of the lignite power plants, since the raw lignite, which is comparable to earth, was stored in heaps and mostly froze. On January 14, 1987, Unit 13 was shut down and the generator was disconnected from the grid. Since a window pane had been smashed in the switch house, condensation water froze in the compressed air line of a circuit breaker . This led to a single-phase, two-phase switch-back of the generator. Strong asynchronous moments now acted on the rotor of the generator. It accelerated and began to vibrate strongly, which in turn resulted in strong vibrations on the generator and the surrounding nacelle. This could have been remedied by a generator load switch provided for in the Soviet projects and on all twelve 210 MW units. There was no short circuit and the load switch would have been in the warm machine house. The generator was coupled to the turbine via a connecting shaft (approx. 50 cm in diameter). The head of this shaft and the connecting bolts were sheared off by the forces involved. A massive bearing block, which carried the connecting shaft at this point , was thrown away a few meters. Flying debris tore up numerous lines, such as those for the hydrogen cooling and sealing oil systems. The hydrogen ignited explosively. The control system of the generator's sealing oil system was so safe that neither the two three-phase motor pumps nor the direct current motor pump could be switched off. As a result of the enormous heat, the now softened steel girders of the roof structure and the front row of windows of the machine house buckled and the approximately 22 m high building collapsed. The fire also affected the nacelle of Unit 14, the generator of which was disconnected from the grid after a short time via an emergency shutdown. The remainder of the building was filled with rubble up to a height of about 11 m, the upper edge of the base of the wall construction.

This failure of 1000 MW led to noticeable bottlenecks in the electrical power supply of the GDR in the following months. The State Council of the GDR initiated an investigation to rule out an initially suspected act of sabotage. The fact that no one was fatally injured in an accident of this magnitude must be described as great luck.

The consequences of the accident were remedied at high pressure, that is, initially the contingents of NVA soldiers for evacuation were increased and later replaced by heavy equipment from West Germany and skilled workers. However, the restart was delayed from February / March to October / November 1987.

The 750-kV interconnected energy lines from the Soviet Union to Eastern Europe worked very well in this cold period, as they were stable at around 5000 MW. Only the GDR only contributed a low single-digit percentage to the construction costs of these expensive lines and accordingly received little energy and had to expect little. For this reason, electricity imports from Austria via Czechoslovakia and Poland to the GDR were started.

Accident in September 2000

Another serious accident occurred on September 10, 2000, in which people were also injured. An uncontrolled steam leaked out of a burst main steam pipe and severely scalded two employees. The two injured were flown to special clinics in Berlin and Leipzig. One of the two employees was injured so badly that he died. An adjacent coaling plant and facilities in the neighboring block were also damaged.

Block R

On October 16, 2006, the earthworks began for another power station block ( Block R ) with an output of 675 MW. The foundation stone was laid on April 13, 2007. In order to supply the new block with coal, the deferred opencast mine in Reichwalde was reactivated by the operator at the time, Vattenfall Europe Mining (formerly LAUBAG ). So that the higher amount of coal can be kept and made available for the power plant, a new bulk material depositing and retrieval device (bucket wheel excavator combined with a small depositing device) was built on the coal storage area of the power plant from June to October 2009.

On February 16, 2012, at 9:58 a.m., the first grid connection took place, in which electricity from Block R was fed into the network. After the subsequent test phase and a planned two-month trial operation, during which electricity was not continuously fed in, the block officially started continuous operation in October 2012. Commissioning was delayed by two years compared to the original plan because, as with other coal-fired power plant projects, there were problems with the T24 steel grade used in the boiler. This is one of the reasons why construction costs rose to around 1 billion euros - a quarter more than anticipated. According to the operator at the time, Vattenfall, the maximum possible efficiency should be up to 43.7%.

- Height of the boiler house: 135 meters

- Height of the cooling tower: 155 meters

Dismantling the chimneys

In 2000, the dismantling of the chimney of Plant 3 began as the first of four 300 m high reinforced concrete chimneys. Due to the nearby flue gas cleaning and ash removal systems, it was not possible to carry out an explosion . For this reason, a special demolition machine with three attached special excavators with hydraulic demolition claws of 500 t was used. In this way, the shaft and the lining masonry were broken off in segments. The demolition machine was lowered to the newly created work level by extending and retracting the rotating support platforms. In the same sequence, the chimney was removed in sections. The concrete demolition was carried out inside via a fox opening . An outside climbing platform ensured protection against inadvertently falling demolition material over the outside. The 300 m chimneys of the Jänschwalde power plant are removed in the same process .

Of the three remaining 300 m chimneys, two were blown up on May 9, 2009 at around 11 a.m. To make this possible, the former coaling plant and a coal belt bridge had to be dismantled. The third chimney should not be blown up because of its proximity to the active power plant, after an explosion in the Schwarze Pump power plant in 1999 resulted in undesirable destruction. It was supposed to be dismantled gradually from the inside out, but the undocumented, very massive reinforced concrete construction did not allow complete dismantling in this way. Ultimately, the shell of the gutted chimney was blown up on October 6, 2012 at 11:00 a.m.

- Blast on May 9th, 2009 viewed from the shores of the Bärwalder See

Emission of pollutants and greenhouse gases

Power plant Critics the high emissions of the power plant Boxberg nitrogen oxides , sulfur oxides , mercury and particulate matter , to the cancer -generating substances ( lead , cadmium , nickel , PAK , dioxins and furans ) can adhere. A study commissioned by Greenpeace at the University of Stuttgart in 2013 came to the conclusion that the fine dust emitted by the Boxberg power plant in 2010 (before Unit R was put into operation) and the secondary fine dusts formed from sulfur dioxide , nitrogen oxide and NMVOC emissions were statistically 1,756 lead to lost years of life. On the list of “Germany's most health-damaging coal-fired power stations”, the Boxberg power station therefore ranks sixth. Vattenfall criticizes this study for “[…] ignoring important facts and findings on the subject of emissions with the clear intention of using coal as an energy source to discredit and scare people ”and refers to the fact that his power plants clearly undercut the legal emission limit values .

In addition, in view of climate change, the CO 2 emissions of the power plant are under criticism. On the list of the most climate-damaging power plants in the EU published by WWF in May 2007 , the Boxberg power plant was ranked 10th in Europe and 6th in Germany (1,100 g CO 2 per kilowatt hour) after the Niederaussem , Jänschwalde , Frimmersdorf power plants , Weisweiler and Neurath . In absolute numbers, the Boxberg power plant had the seventh highest carbon dioxide emissions in Europe in 2006, after the Bełchatów power plant (Poland), the four German lignite power plants mentioned and the Drax power plant (England).

The Boxberg power plant reported the following emissions in the European " PRTR " pollutant register :

| Air pollutant | 2007 | 2010 | 2011 | 2012 | 2013 |

|---|---|---|---|---|---|

| Carbon dioxide ( CO 2 ) | 16,300,000,000 kg | 15,100,000,000 kg | 16,200,000,000 kg | 15,900,000,000 kg | 19,200,000,000 kg |

| Sulfur dioxide (as SO x / SO 2 ) | 9,880,000 kg | 7,810,000 kg | 11,400,000 kg | 11,700,000 kg | 14,000,000 kg |

| Nitrogen oxides ( NO x / NO 2 ) | 10,700,000 kg | 10,700,000 kg | 11,200,000 kg | 11,300,000 kg | 14,000,000 kg |

| Carbon monoxide ( CO ) | 4,790,000 kg | 4,570,000 kg | 5,990,000 kg | 5,550,000 kg | 6,530,000 kg |

| Particulate matter ( PM10 ) | 202,000 kg | 167,000 kg | 277,000 kg | 600,000 kg | 460,000 kg |

| Nitrous oxide ( N 2 0 ) | 172,000 kg | 171,000 kg | 191,000 kg | 191,000 kg | 238,000 kg |

| Inorganic Chlorine Compounds (as HCl ) | 95,400 kg | 92,100 kg | 118,000 kg | 93,400 kg | 104,000 kg |

| Lead and compounds (as Pb ) | 263 kg | 236 kg | 326 kg | not specified | 324 kg |

| Mercury and compounds (as Hg ) | 110 kg | 226 kg | 273 kg | 235 kg | 370 kg |

| Chromium and compounds (as Cr ) | not specified | not specified | 182 kg | 168 kg | 170 kg |

| Nickel and compounds (as Ni ) | 311 kg | 152 kg | 230 kg | 87 kg | 79 kg |

| Copper and compounds (as Cu ) | not specified | 104 kg | 130 kg | 104 kg | not specified |

| Arsenic and Compounds (as As ) | not specified | not specified | not specified | 50.6 kg | 58 kg |

| Cadmium and Compounds (as Cd ) | not specified | not specified | 22 kg | 13.7 kg | not specified |

No other typical pollutant emissions were reported, as they are only required to be reported in the PRTR from an annual minimum amount, e.g. B. Dioxins and furans from 0.0001 kg, cadmium from 10 kg, arsenic from 20 kg, chromium from 100 kg, lead and zinc from 200 kg, inorganic fluorine compounds from 5,000 kg, ammonia and nitrous oxide (N 2 O) from 10,000 kg , volatile organic compounds other than methane (NMVOC) of 100,000 kg.

The European Environment Agency has estimated the cost of damage to the environment and health of the 28,000 largest industrial plants in Europe on the basis of the emission data reported in the PRTR using the scientific methods of the European Commission. According to this, the Boxberg power plant causes the eleventh highest damage costs of all European industrial plants.

| cause | Damage costs | unit | proportion of |

|---|---|---|---|

| Boxberg power plant | 0.713-1.059 | billion euro | 0.7-1.0% |

| A total of 28,000 systems | 102-169 | billion euro | 100% |

Shutdown

On January 16, 2020, the federal government decided that the first two units (Units N and P, Plant 3) at the Boxberg coal-fired power plant should be shut down by the end of 2029 and the remaining units by 2038.

See also

- List of power plants in Germany

- List of fossil fuel power plants in the European Union with the highest carbon dioxide emissions

Web links

- Vattenfall Europe data sheet ( Memento from July 16, 2015 in the Internet Archive ) (PDF; 423 kB)

- History and many pictures of the power plant

- New block R

Individual evidence

- ↑ LEAG's Power Plants division .

- ↑ Federal Network Agency power plant list (nationwide; all network and transformer levels) as of July 2nd, 2012. ( Microsoft Excel file, 1.6 MiB) Archived from the original on July 22, 2012 ; Retrieved July 21, 2012 .

- ↑ Network load in the control area. 50Hertz Transmission GmbH, accessed on March 29, 2020 .

- ↑ Joachim Scheer (2001). Failure of Buildings, Vol. 2, Buildings and Special Buildings: Volume 2: Buildings And Special Constructions, Ernst and Son, ISBN 978-3-433-01608-4

- ↑ SW Usov, WW Kantan and others: Electrical part of power plants. Energija, Leningrad 1977.

- ↑ Studies on an outline of the history of electrical power generation in the area of the GDR since 1945. ORGREB Institute for Power Plants, Vetschau 1984.

- ↑ Overshadowed celebration ( memento of November 13, 2004 in the Internet Archive ), kraftwerke-online.de, September 17, 2000.

- ↑ New power plant in Boxberg goes into operation step by step. ( Memento of February 11, 2012 in the Internet Archive ) In: MDR , January 12, 2012. Retrieved January 27, 2012.

- ↑ Harriet Stürmer: New power station on the network. In: Märkische Oderzeitung , October 11, 2012. Retrieved October 12, 2012.

- ↑ To regulate new lignite power plants faster. ( Memento from February 5, 2013 in the web archive archive.today ) In: VDI nachrichten , April 13, 2012.

- ↑ Regina Weiß: Boxberg power plant sets new standards. In: Lausitzer Rundschau . March 14, 2012, accessed March 29, 2020 .

- ↑ Fine dust sources and damage caused , Federal Environment Agency (Dessau)

- ↑ Assessment of Health Impacts of Coal Fired Power Stations in Germany - by Applying EcoSenseWeb (English, PDF 1.2 MB) Philipp Preis / Joachim Roos / Prof. Rainer Friedrich, Institute for Energy Economics and Rational Use of Energy, University of Stuttgart , March 28, 2013

- ↑ Greenpeace: The ten most unhealthy coal-fired power plants in Germany. (PDF; 129 kB)

- ↑ Low emissions from Vattenfall's lignite power plants ( memento from April 29, 2013 in the web archive archive.today ), press release from Vattenfall from April 3, 2013

- ^ Dirty Thirty Ranking of the most polluting power stations in Europe. WWF, May 2007 (PDF)

- ↑ PRTR - European Emissions Register

- ↑ Regulation (EC) No. 166/2006 of the European Parliament and of the Council of January 18, 2006 on the creation of a European Pollutant Release and Transfer Register and amending Council Directives 91/689 / EEC and 96/61 / EC ( PRTR regulation).

- ↑ Cost-benefit analysis of air quality policy , Clean Air for Europe (CAFE) program, European Commission

- ↑ a b Revealing the costs of air pollution from industrial facilities in Europe , European Environment Agency , Copenhagen, 2011

- ↑ Timetable for the coal exit - the reactions from Saxony. MDR.DE, January 16, 2020, accessed on January 17, 2020 .