Tiled stove

A tiled stove is a heating stove for house fires that is suitable for heating one or more living rooms . Stoves are usually made of stove tiles set, but there are also tiled stoves, which consists predominantly of brick masonry are plastered. It was not until the 19th and 20th centuries that the tiled stove in the combustion chamber was increasingly lined with firebricks or provided with trains.

Due to their large mass, tiled stoves are able to absorb the large amount of heat generated when burning fast- burning solid fuels and then release it into the room over a longer period of time. The tiled stove used to be used to dry laundry and other things. In a built-in heating compartment, water and food could be kept warm or cherry stone pillows could be warmed up. In the firing system ("oven") in some areas, people cooked or baked bread.

Heating with coal , briquettes or coke was not common before the 20th century, as this required grate firing , which was normally not available in the classic basic furnace of the 11th to 19th centuries. The tiled stoves built in the 20th century are mostly also suitable for operation with lignite briquettes or - in the case of long-burning or hot air stoves - with coke.

history

Historians assume that the ovens or vaulted hearths built into the houses were the forerunners of the tiled stoves in cold areas. At an unknown point in time in the Middle Ages , ceramic cup tiles or pots began to be inserted into the clay domes of the ovens to improve heat radiation. However, this is by no means backed up by clear archaeological finds and findings. The oldest ceramic objects that are considered to be stove tiles have so far been found in Alsace , the federal state of Baden-Württemberg and north-western Switzerland. You will be in the time of the 8./9. Century and could have belonged to stoves that worked on the muzzle-loading principle and were set up in the corners of the room. It was only at a later point in time, probably in the course of the 11th century, that the rear- loading tiled stove developed from this . H. from the kitchen.

The smoke from the burning fuel initially withdrew through the fire opening into the black kitchen . The stove itself was in another room, which thus remained smoke-free, which meant a significant improvement in the quality of living and living. The parlor , the central living and working space of the Middle Ages, was created.

Barely 100 years later, the first tiled stoves were also in the rooms of North German Hanseatic cities. By 1200, the tiled stove was often part of the standard equipment in castles, monasteries and city houses.

With the development of the stove tiles decorated in relief, the tiled stove also assumed a decorative function from the 14th century at the latest. The distribution area of the tiled stove finally included the German-speaking area of Central Europe and peripheral zones in northern Italy, Alsace, France, the Netherlands and England. Residential tiled stoves were now also found in Scandinavia and the Baltic States under the influence of the Hanseatic League (Denmark, Sweden, Finland, Estonia, Latvia, Lithuania) as well as in Russia, Poland, the Czech Republic, Hungary, Romania, Slovenia and Croatia.

The oldest furnace of this type that has been reliably dated to date was excavated in Winterthur in Switzerland and can be dated to the year 1208. Like all early tiled stoves, it was made of clay and mug tiles . The early mug or pot tiles were made by the stoner , who was usually also the stove fitter . This applies in almost all regions of the distribution area of the tiled stove until the 19th and 20th. Century.

Finds indicate that the tiled stove was initially reserved for the monasteries , the nobility and the patricians . Simple brick stoves continued to be used in ordinary homes.

In the course of the further development of the tiled stove, a variety of stove tile types and tile decors such as:

|

|

|

It was only from the Baroque onwards that a new production technique was developed that made larger and freely shaped stove tiles or tiled stove parts possible, the so-called overlap technique . With this technology, individual tiled stoves are still manufactured to order. The bulk of the tiled stoves, however, was made up of smaller-format sheet, corner and cornice tiles.

Fireplaces were often the cause of fires in the 18th century . Orders issued by Count Palatine Karl IV. From 1772 served to prevent such fires. So no more wooden chimneys and no wooden shafts to guide the smoke from the fireplace to the fireplace were allowed to be built. It was also forbidden to lead stove pipes out of the window.

Technical development

to form

The exterior design of the tiled stoves went through a great art-historical development, but the heating technology remained unchanged for a long time until the 18th century began to evacuate the stove smoke via chimneys. Until then, tiled stoves with open heating doors were mostly fired from the kitchen or an adjoining room and the flue gases were also released there into the open fireplace. A lower part of the ovens was built onto and through the wall of the room and was loaded with wood through the wall (breech-loader principle). In the higher part, accumulated heat formed, which was released to the tile walls. The tile walls in the radiation area of the fire were warmed up more. When the fire burned down, the heating doors were closed and the tile walls released the stored heat to the rooms, depending on the thickness of the brickwork. The flue gases emerged through the oven door after cooling down during the heating phase and withdrew through the forge , which was mostly located in the kitchen above the open stove. Often the exhaust gases simply leaked into the open through leaks in the roof structure. Back then, tiled stoves made better use of fuel than open fireplaces, but they were still very ineffective.

At the end of the 17th century and then in the 18th century the first serious thoughts were given to energy-saving stoves, and for example Frederick II of Prussia organized a competition on wood-saving stoves. There were even suggestions for ovens that stretched over two floors. But only the direct connection to a chimney made it possible to install flue gas ducts in the tiled stoves. It was a gradual process of experience to deal with the negative pressure in the chimney and in the fireplace, so that falling drafts (lintel drafts) and other drafts became possible. It cannot be precisely timed. Up until the 20th century there were still open stoves operated without a chimney in the Black Forest. By redirecting and cooling the heating gases in the trains, the stoves became very effective and economical with wood, which is now scarce due to deforestation. Grate, ash pan and targeted combustion air flow were now common.

External dimensions and standards

Tiles were gradually produced as mass-produced goods in factories, the size adapted to the respective heat requirements and standardized across the country by means of craft rules . In some cases, there were also technical setbacks when, in the historicism of the second half of the 19th century, old oven shapes appeared again and the old breech-loading ovens were built again.

The DIN standards for the tiled stove were created in 1925 from the craft rules and empirical values for space heating , which were converted into the imperial principles and were called DIN standards again after the Second World War . The DIN 1289 fire cabinet for tiled stoves; The filling door for filling firing from 1928 is still valid today. The DIN standard divided the tiled stoves into a light, medium-weight and heavy design, depending on the thickness of the outer wall, and provided planning values for room heating capacity, mass and storage duration.

Development of heating inserts in the tiled stove

The advent of coal as a fuel in the 19th century led to changes in the tiled stove design. The fire door could be smaller. The hot bed of embers of the coal lasted longer, which is why direct thermal contact with a large mass of heat-storing ceramics was no longer absolutely necessary (see also long-burning stove ). Over various stages of development, compact cast-iron heating inserts lined with chamotte were obtained, which contained all furnace components (grate, ash pan, oven doors) and were revisionable . You could repair these firings without having to dismantle the whole tiled stove. The heating inserts were cooled by convective air flow. This air brought an increase in room heating capacity. This is how the first hot air tiled stoves came about. They were able to heat the rooms quickly, and at the same time also stored heat in the tiled building. The warm air could be adjusted to the heating requirement by means of blinds and could also be directed to other rooms or floors.

Tiled stove design through the ages

The design of the tiled stove has changed fundamentally over the last few decades. Until the 1970s, tiled stoves - according to their name - were still completely tiled, but in the 1980s and 1990s there was more and more abandonment of classic stove tiles. Plastered surfaces with cornice tiles and some decorative elements made of ceramic dominated the furnace design at this time. There was also a trend towards as many gradations and staggered levels as possible. Since the beginning of the new millennium, however, more and more simple, puristically designed systems have found their way into living rooms. Clear lines, straight, plastered surfaces and large windows determine the picture. Many manufacturers of classic stove tiles have reacted to this trend and offer large-format ceramics as an alternative to the popular natural stone (granite, slate, sandstone ...) for fire tables and benches. In any case, the classic green stove tile seems to have had its day. Today, in combination with white plastered surfaces, rich brown or black tones often define the picture as a contrast.

The changes in style can also be made clear with the help of St. Epimachus : As his distinguishing feature, he holds a tiled stove in his hand, which has been constantly adapted in the course of history in accordance with the times and fashion.

Impact on the environment

Principles

Tiled stoves can contribute to non-fossil heating, i.e. to avoid CO 2 , as they can be fired with wood and wood briquettes. To be sustainable, however, it must come from sources that do not represent overexploitation of the forests. The construction and operation must match the fuel in order to heat efficiently and with low emissions.

Depending on the fuel, construction and operation, however, tiled stoves can emit considerable amounts of pollutants in the form of gases, dusts and aerosols. This can also affect the operator, at least when cheering on and when the move is unfavorable.

Salts , in part as fly ash, are also formed when completely burned. Salts / ash are a minor problem in the tiled stove in terms of environmental impact: under the operating conditions in the tiled stove, they clump together to form macroscopic dust or fly ash and can no longer be assigned to fine dust and for the most part also not respirable or harmful. An exception is the burning of lacquered wood, for example: the pigments can be released, e.g. B. lead oxide if it is old white paint. The use of filler-containing paper for firing leads to high fly ash emissions and also pollutes the furnace passages.

Types and causes of pollutant emissions

Incomplete combustion

Incomplete combustion in the tiled stove creates soot , carbon monoxide and polycyclic aromatic compounds . With regard to lower soot emissions, hardwood is preferable.

Briquettes contain a minimum amount of oil and tar due to their production, which is particularly problematic if the combustion is incomplete.

Incomplete combustion in the tiled stove has various causes:

1. Stopping the ignitability of the exhaust gases in the heating-up phase by components that extract heat too quickly or by cold combustion air.

Problem solution through modern tiled stove inserts or basic furnace systems with combustion air preheating and post-combustion zones.

2. Insufficient air supply due to operating errors or system errors .

One problem is heating (especially with wood) without a storage medium, for example in a draft-controlled long-life stove: only when there is only embers without flames does a lack of oxygen not lead to pollutants, otherwise the power reduction of a furnace is associated with increased pollutant emissions.

Wood firing systems in particular should and cannot be throttled; they should either be operated at full power or not at all. This requires a heat storage device that can absorb a high level of heat output and a large amount of energy. In principle, heavy tiled stoves can do this, but they are often designed for coal (small combustion chamber) and can suffer from the high heat output of a wood fire.

As soon as there are no more flames, a tiled stove can and should be completely closed in order to avoid heat loss through the draft through the stove, which is hot inside.

Use unsuitable fuels

Burning household rubbish , lacquered wood or even printed paper in the tiled stove is associated with high risk of harmful substances. Burning unauthorized fuels is a criminal offense in Germany, among other places. In order to investigate this, the district master chimney sweep can take soot samples that can prove operation with non-approved fuels.

Sulfur compounds are a problem with coal firing. There are big differences in the sulfur content of brown coal briquettes. In the past, briquettes were also sold from the areas around Leipzig - they are known for their high sulfur content. The same applies to coal imported from the Czech Republic (Bohemia). In contrast, the coal used today from the Lausitz region is lower in sulfur.

Pollutants from scorching dust

A hot-air tiled stove consists of a mostly ceramic shell on the outside and a cast-iron insert on the inside. This can be heated to 300 ° C and more using wood, coal, heating oil or gas. Air circulates between the insert and the envelope, which heats up and rises as a result. In addition, cold air is constantly drawn from the floor. With this air, the dust in the room is drawn to the stove, and the phenomenon of dust scorching occurs on the hot insert. This involves pyrolysis and disintegration of large dust particles into countless smaller dust particles, with the result that carcinogenic fine dust is formed, which is then found in the room air.

Designs

Basic forms of the tiled stove are the basic stove , the hot air stove and the combi stove . Special forms are the tile art, the warm air central heating and the hypocaust stove.

Basic furnace

A basic furnace is a system built by hand on site, consisting of a combustion chamber and ceramic heating flues connected downstream.

There are three variants, which are differentiated according to their storage mass: light, medium and heavy construction. A basic furnace is a time-burning furnace. The fuel, wood, is burned down in a certain time and the heat generated in the burn is stored in the firebrick , which is gradually released through the surface. The post-heating time (putting on the fuel) is usually eight, twelve or twenty-four hours, depending on the heat storage capacity of the basic furnace. With a rustless furnace (depending on the construction) only wood can be used as fuel.

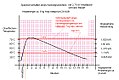

Warm air tiled stove

This type of tiled stove works on the principle of convection heating. Cold room air flows through the lower opening (usually a round arch in the base) into the interior of the tiled stove, where it is heated by the hot iron parts and flows back into the room as warm air. This warm air can also be conducted into adjacent rooms or floors above by means of warm air ducts. The warm air makes up 60 to 80% of the heat emitted, the rest is radiant heat emitted via the tile surface. The warm air tiled stove gives off heat quickly and economically.

Combination tiled stove

The combi-tiled stove is a mixture of a hot-air stove (the heating element) and a radiant stove (masonry trains). This is currently the best furnace system because a heating insert with modern combustion technology that can be exchanged if required (room air-independent combustion air supply, special types for other types of fuel such as pellets , briquettes , oil or gas ) can be installed. The masonry puffs are directed along the furnace wall so that the greatest possible amount of heat can be released into the room. Further advantages are the quick release of heat from the heating element (approx. 15 to 20 minutes) and a storage time of between 6 and 12 hours for the ceramic train.

Fireplace

The functional principle of the fireplace stove largely corresponds to that of the hot air stove. However, heating chimneys have a more or less large pane of glass through which you can watch the burn. One advantage of the fireplace over the hot air stove is the higher proportion of radiant heat. Immediately after the start of heating, this reaches the installation room through the window and thus ensures a more pleasant temperature sensation. For a number of years now, many fireplace inserts have also been able to heat from the back - e.g. B. from the hallway. The window then only needs to be opened for cleaning purposes. By adding a brick-built flue to the fireplace, you can achieve the functionality of a combi stove. The window should not be too large, however, as this leads to excessive heat loss from the combustion chamber and thus the heat storage capacity of the system is reduced.

(Tile) art or Chust

The art of tile is traditionally at home in the Black Forest and Switzerland. The exact origin is unknown. The development of art also depends on the development of the stove from which it is fired. Originally, people cooked over an open fire, there was a forge (or nothing at all) above the stove , and next to it was the fire hole of the vaulted room oven. About 200 years ago the use of a chimney gradually gained acceptance, the stove was given an iron hob and the tiled stove a chimney connection. The food (if any) was closed and extended downwards and used as chimneys.

In order to divert the exhaust gases from the stove, the art (Chust or Chouscht) with its own heating gas flue was attached to the tiled stove in the room. The art of that time was a sometimes two-story heated bench with a sandstone cover, which was heated independently of the actual tiled stove. The historical art benches were very high, because at that time people did not trust themselves to lead exhaust gases downwards, and the stoves were also very low. In order to be able to sit on the high bench seats, you often needed an artificial bench made of wood to put your feet on. Today's tile arts have broken away from the tiled stove and form independent heating systems that are very efficient because they combine the function of cooking with the function of heating, and are particularly popular in Switzerland and southern Baden-Württemberg.

Warm air central heating

Warm air central heating was a special form of the tiled stove in Germany in the 1950s and 1960s, before hot water central heating emerged. It used the high heating power available through the development of the heating inserts and sheet metal heating registers and distributed it through air ducts in the rooms of single-family houses. The tiled stove shown in the adjacent picture heated three rooms on the ground floor and another five rooms on the first and second floors. The hot air pipes for the upper rooms led through the protruding wall visible above the stove. They could be opened or closed for the individual floors from the ground floor.

Air hypocaust systems

They are a special form of the hot air tiled stove. With a closed air circulation system that works by gravity or with a fan, more distant components, e.g. B. the bench of a tiled fireplace or the walls of a room, heated. The enclosed, up to 200 ° C hot system air does not come into contact with the room air. Hans Kurt Zeidler developed this system in 1983 and made it known in the market.

Hot water connection

A special form of the tiled stove are the hot water stoves. These have a connection for a hot water tank. The built-in circulation pump in the central heating then pumps the warm water from the tank into the boiler (hot water tank). From there the water is then directed to the hot water taps.

Hypocaust tiled stove

In the case of a conventional tiled stove, heat is also convected in addition to the heat being given off to the surrounding air. The amount / dose depends on the surface temperature of the oven - the cooler the lower. The areas of the outer surface that are in closer contact with the hot flue gas flues heat up more, which leads to higher convection. As a result of the inhomogeneous distribution of heat, there may also be tension in the furnace, which can lead to unwanted cracking and breakouts. The hypocaust building system was developed to eliminate the disadvantages mentioned . Here, the trains consist of ceramic module storage stones (KMS stones, the so-called storage core) according to the desired heating output. The air space remaining between the firebrick panels and the storage core does not release the resulting heat into the room through heat conduction as in conventional construction, but through radiation. Inside the system, since the outer shell is closed, there is convective heat transport from hotter surfaces to colder areas, which are thus also heated and increase the effectively available warming area. According to the first thermodynamic law , the usable amount of heat generated in the furnace is identical for every type of tiled stove. The amount of heat distributed over a larger area therefore leads to lower surface temperatures of the stove and, from a physiological point of view, creates a more pleasant, comfortable room climate.

hazards

Operating errors can smolder the fuel, releasing explosive gases. A deflagration or explosion leads to damage or destruction of the stove, parts of the structure to be blown off and embers or fuel to be thrown out. The combustible gases developed by the fuel can deflagrate after a temporary lack of air. Only when these have been completely driven out and burned (no more flames) can the oven door be safely closed. Only the remaining carbon (flameless embers) can burn even in the absence of air.

As long as coal or wood still develops flames, the air supply should not be interrupted, otherwise incomplete combustion will occur, u. a. creates carbon monoxide , which can get into the room to be heated.

If the combustion is incomplete, soot and tar deposits form in the chimney, which can cause a chimney fire.

Physical basics

Wood burns for the most part in gaseous form in long flames and with high instantaneous heating power. The conversion of the wood to gas begins at around 80 ° C and cannot be interrupted; d. H. the gas must also be burned off when it is generated in order to avoid incomplete combustion. Extended combustion (endurance burning) is not possible with (log) wood firing in stoves. Unfortunately, in stoves without storage masses, attempts are made again and again to burn wood with a delay by greatly reducing the combustion air, with dire consequences for the systems, chimneys and the environment. The tiled stove is traditionally and now increasingly a storage stove that buffers the current very high heating output of a wood fire and releases it to the rooms with a delay, but only if it has the required storage mass (see combi-tiled stove, basic stove, tiled stove art).

See also

literature

- Rosemarie Franz: The tiled stove . Akademische Druck und Verlagsanstalt, Graz 1981 (outdated state of research).

- Eva Roth Heege: Oven ceramics and tiled stoves - typology, terminology and reconstruction in German-speaking countries (CH, D, A, FL) with a glossary in seventeen languages. With contributions by Monika Dittmar, Julia Hallenkamp-Lumpe, Andreas Heege, Matthias Henkel, Klaus Hufnagel, Uwe Lamke, Katja Lesny, Margret Ribbert, Harald Rosmanitz and Günther Unteidig. Schweizerischer Burgenverein, Basel, 2012. ISBN 978-3-908182-23-8 , 432 pages, 326 colored text images, stove tile glossary (17 languages) with 557 S / W sample images (= Swiss contributions to the cultural history and archeology of the Middle Ages , vol. 39).

- Annamaria Matter, Werner Wild: New findings on the appearance of tiled stoves of the 13th and early 14th centuries. Findings and finds from the canton of Zurich , in: Mittelalter-Moyen , Age-Medioevo-Temp medieval 2, 1997, pp. 77–95.

- Annamaria Matter, Werner Wild: Early tiled stoves from the canton of Zurich: Archaeological finds and findings (12th to 15th centuries) , in: Werner Endres, Konrad Spindler : Contributions from the 34th International Pottery Symposium at Maretsch Castle in Bolzano, South Tyrol 2001 (Nearchos 12), Innsbruck 2003, pp. 261-269.

- Karl Heinz Pfesttorf: Tiled stoves and chimneys built according to the craftsmanship: Heat requirement - chimney construction, tiled stove warm air heating, basic tile stoves, chimney - combustion, heat - flow , 4th edition, Verlag für Bauwesen, Berlin 1996, ISBN 3-345-00600-6 / Bauverlag Wiesbaden 1996, ISBN 3-7625-3340-7 .

- Thomas Schiffert: Kachelofen 2000 (= dissertations of the Technical University of Vienna , Volume 71), Österreichischer Kunst- und Kulturverlag, Vienna 1996, ISBN 3-85437-124-1 (Dissertation TU Vienna 1995, 227 pages).

- Gerhard Wild: Build your own stoves and chimneys , Compact, Munich 2003, ISBN 3-8174-2268-7 .

- Jürg Tauber: stove and oven in the Middle Ages. Studies on the cultural history of archaeological material, primarily from north-western Switzerland, 9.-14. Century (= Swiss contributions to the cultural history and archeology of the Middle Ages , volume. 7), Walter, Olten / Freiburg im Breisgau 1980, ISBN 3-530-87101-X (dissertation at the University of Basel 1980, 412 pages).

Web links

- Everything about the archeology of the tiled stove

- A tiled stove from Bavaria

- University of Göttingen Dissertation on the history of the tiled stove

- A short cultural history of the tiled stove at Monumente Online

- Rudolf Schnyder: furnace construction. In: Historical Lexicon of Switzerland . 2015 .

- Tiled stoves of the 18th and 19th centuries Jhs. in Switzerland

- Tile research in Innsbruck

Individual evidence

- ^ Franz-Josef Sehr : The fire extinguishing system in Obertiefenbach from earlier times . In: Yearbook for the Limburg-Weilburg district 1994 . The district committee of the Limburg-Weilburg district, Limburg-Weilburg 1993, p. 151-153 .

- ↑ Research on www.beuth.de from Beuth Verlag

- ^ Taken over in parts, heavily revised and adapted to the context from Der Kachelofen by Rosemarie Franz, ISBN 3-201-01172-X .

- ↑ Functionality of a hypocaust furnace with building examples , accessed on January 3, 2019.