natural gas

Natural gas is a flammable, naturally occurring gas mixture that occurs in underground storage facilities . It often occurs with petroleum because it is created in a similar way. Natural gas mainly consists of highly flammable methane , but the exact composition depends on the deposit. Sometimes it is necessary to prepare the raw gas in order to separate toxic, corrosive and / or chemically inert (non-flammable) components or to enrich methane. Whenever “natural gas” is spoken of in general or in a technical context, then it is usually very high methane-rich natural gas in consumer quality.

As a fossil fuel , natural gas is mainly used to heat residential and commercial spaces, as a heat supplier for thermal processes in trade and industry (e.g. in large bakeries, brickworks , cement works , and in the mining and heavy industry ), to generate electricity and as fuel for Ships and automobiles . In addition, there are significant quantitative applications as a reaction partner in chemical processes, where its energy content is also used. These are, for example, ammonia synthesis using the Haber-Bosch process ( nitrogen fertilizer ), iron ore reduction in the blast furnace process or the production of hydrogen .

properties

General

Natural (raw) natural gas is a hydrocarbon- containing gas mixture, the chemical composition of which fluctuates considerably depending on the site, due to the prevailing conditions during formation, migration and residence in the deposit.

The main component is usually methane . In many natural gas reservoirs, this proportion is between 75 and 99 mol% . Raw gas with increased proportions of ethane (1% to 15%), propane (1% to 10%), butane , ethene and pentanes is called wet natural gas , which refers to these gaseous hydrocarbons that are easily liquefied under pressure, also known as natural Gas Liquids (NGL) are called. The term wet natural gas is also used for raw gas with a relatively high proportion of water vapor ( dry natural gas generally has a low proportion of easily condensable gases, be it NGL or water vapor). Raw gas with a very low methane content (e.g. 30%) is called lean gas .

Other secondary components of raw gas can be: hydrogen sulfide (often between 0% and 35%), nitrogen (often between 0% and 15%, in extreme cases up to 70%) and carbon dioxide (often between 0% and 10%). Raw gas with a significant hydrogen sulfide content is called sour gas . In addition, it can contain a considerable amount of strong-smelling organic sulfur compounds ( alkanethiols , carbonyl sulfide ). Furthermore, raw natural gas contains noble gases . Raw gas, which contains up to 7% helium , is of great value and the main source of helium recovery.

Hydrogen sulphide, carbon dioxide and water must first be separated using processes such as gas scrubbing (especially desulphurisation ), as some of them are poisonous, burn to environmental pollutants (e.g. sulfur dioxide ), have a corrosive effect or have a stronger tendency to hydrate than methane . Up to 28,000 tons of secondary components can accumulate on an offshore production platform every day.

In addition to the gases mentioned, raw gas can also contain solid components such as grains of sand or clay particles from the deposit rock, as well as some elemental sulfur (a few grams per cubic meter) and mercury (a few milligrams per cubic meter). These substances must also be separated beforehand because they are toxic and / or cause damage to conveyor and transport systems.

Physical-technical properties

Natural gas is a flammable, colorless and usually odorless gas with an ignition temperature of around 600 ° C. It has a lower density than air. Approximately 10 cubic meters of air are required to completely burn 1 cubic meter of natural gas. During combustion, the main reaction products are water and carbon dioxide . In addition, small amounts of nitrogen oxides , sulfur dioxide , carbon monoxide and dust can be produced. In order to be able to perceive any pipe leaks olfactorily , treated natural gas is provided with a fragrance before it is fed into the network. In this odorization process, thioethers (for example tetrahydrothiophene ) or alkanethiols (for example ethyl mercaptan and tertiary butyl mercaptan ) are primarily added in very small amounts. These fragrances, and not the main components of natural gas, are responsible for the classic gas smell.

From a technical point of view, natural gas is a fuel gas . Within the fuel gases, it is included in gas family 2 (methane-rich gases) in accordance with DVGW worksheet G260. These are divided into two types according to their Wobbe index , which is a measure of the energy content (energy density) and depends on the exact composition of the gas: H gas (from high [calorific] gas ) has one higher proportion of hydrocarbons and a correspondingly low inert gas (natural gas mainly share nitrogen and carbon dioxide ), while L-gas (of English. low [calorific] gas , low energy content) has a higher inert gas content. H natural gas from the CIS countries used in Germany consists of around 98% methane, 1% other alkanes (ethane, propane, butane, pentane) and 1% inert gases. H natural gas from the North Sea consists of around 89% methane, 8% other alkanes and 3% inert gases. L-natural gas from the Netherlands and Northern Germany consists of around 85% methane, 4% other alkanes and 11% inert gases. The calorific value H s (formerly H o ) varies accordingly between 10 kWh / kg (36 MJ / kg) or 8.2 kWh / m³ (30 MJ / m³) for L-gas and 14 kWh / kg (50 MJ / kg ) or 11.1 kWh / m³ (40 MJ / m³) for H gas. The calorific value H i (previously H u ) is about 10% below these values. The density varies between 0.700 kg / m³ (H-gas) and 0.840 kg / m³ (L-gas). The boiling point of the condensed hydrocarbon fraction is generally somewhat higher than that of pure methane (−161 ° C).

In the classification of test gases for gas devices, a distinction is made according to (DIN) EN 437 type LL (low-low) and type E (Europe). Type LL corresponds to L gas and type E to H gas.

Emergence

Raw natural gas is often created through the same geological processes that lead to the creation of oil . It is therefore not uncommon for crude oil and natural gas to occur together in one deposit. This natural gas was created in geological time from masses of dead and submerged marine microorganisms (predominantly single-celled algae ), which were initially converted into digested sludge ( sapropel ) on the seabed under oxygen-free conditions . Over the course of millions of years, this can be sunk into deeper regions of the upper crust by subsidence and there exposed to high pressures and above all high temperatures, which ensure the conversion of organic substances into natural gas (see also the formation of petroleum ). Even coal seams contain natural gas. This gas represents a great danger in the coal mining industry as a hitting weather . As coal seam gas , it is extracted from deep coal seams by means of drilling (see also types of deposits ).

Economically viable quantities of natural gas can also arise on site as a result of microbial decomposition of organic sediments, i.e. without significant thermal processes and without significant migration . Gas deposits with this history of origin can be found, for example, in the foothills of the Alps in Upper Austria and Upper Bavaria and in the Vienna Basin . With an age of only 20 million years these are geologically very young deposits.

The helium contained in natural gas comes from radioactive alpha decay of elements that are contained as constituents of minerals in the igneous rocks of the basement of a sedimentary basin. The very mobile helium, like the gaseous hydrocarbons, migrates in the pores and crevices of the rock towards the earth's surface and accumulates in conventional natural gas deposits.

use

History as an energy resource

As early as the 3rd century BC It is said that natural gas was extracted from a well in the Chinese province of Sichuan for the first time and used to fire brine pans . The brine evaporated in it was also extracted from boreholes and the natural gas discoveries were just a side effect of the search for brine. Other sources cite the 11th century AD as the earliest period for the use of natural gas as fuel in the Sichuan salt flats. From the 16th century onwards, the state of the art made it possible to collect natural gas that escaped directly from the increasingly deeper brine wells.

In 1626, French missionaries reported "burning springs" in shallow waters of North America. Major industrial use of natural gas began in the United States in 1825 in the town of Fredonia in western New York . Here a certain William H. Hart dug a shaft for the extraction of natural gas for the lighting of a mill and a house. Hart also used natural gas to illuminate a lighthouse on Lake Erie . He founded the first natural gas company, Fredonia Gas Light Company , in 1858 . Starting in 1884, natural gas was used in Pittsburgh's glass and steel industries. The gas was delivered to the city via a pipeline from Murrysville, now about 35 km east of Pittsburgh. This made Pittsburgh the first city in the world to be connected to a natural gas pipeline.

North America, especially the USA, had the highest use of natural gas in the world until 1950 (US production share in 1950 about 92% of world production, in 1960 US production share of world production 80.2%). In the Federal Republic of Germany , the energy use of natural gas in the early 1960s was only 1% of fossil primary energy, in 1970 it was around 5%.

Originally, natural gas was only flared when producing oil. First, natural gas was used as an energy resource for the economy in the USA (since the early 1920s) and later in Europe (since the 1960s).

In some countries, natural gas is still flared today because it is costly to transport. In the USA, many gas and steam combined cycle power plants have been built in recent years to generate electricity on the basis of natural gas, these have a very high degree of efficiency (60%) and can also use the waste heat as district heating to heat residential buildings.

use

Electricity and heat production

In Germany and in many other industrialized countries, natural gas is mainly used to supply useful heat in industry and in residential buildings. With a share of 25.6%, gases that contain liquefied petroleum gas, refinery gas , coke oven gas and furnace gas in addition to natural gas, accounted for the second largest share of final energy consumption in Germany in 2018. With 30%, fuels and other mineral oil products without heating oils accounted for the largest share. In Switzerland, the share of final energy consumption was 13.5% in 2018. According to forecasts by the International Atomic Energy Agency (IAEA), natural gas will become the most important fossil fuel with a share of more than 50% by 2080.

In some countries, electricity production from gas also plays a major role (Russia: approx. 50% share). Figures from Fraunhofer ISE show that the share of natural gas in electricity generation in Germany was 8.14% in 2018. Natural gas is converted into electricity in gas turbine power plants , combined cycle power plants and gas engine power plants. In Germany, these power plants are primarily used to cover peak loads ; the output of the gas turbines used there can be regulated well (i.e. promptly) compared to coal and nuclear power plants.

Fuel for automobiles

For some years now, natural gas has also been increasingly used as a fuel for motorized vehicles . Storage, transport and refueling take place either as Compressed Natural Gas (CNG, compressed natural gas), i.e. highly compressed but still gaseous natural gas, or as Liquefied Natural Gas ( LNG, liquefied natural gas ), i.e. liquefied and thoroughly cooled down Natural gas kept cool and liquid in special cryotanks .

As a fuel for cars, natural gas should not be confused with LPG . This fuel, which is also abbreviated to NGL ( Natural Gas Liquids ) or LPG ( Liquefied Petroleum Gas ) , does not contain methane, but mainly consists of the longer-chain alkanes propane and butane, which are only present in small quantities in natural gas. The LPG offered at filling stations mostly comes from oil refining .

The advantage of natural gas and LPG is that they burn more cleanly than petrol and diesel. In the case of natural gas / CNG, this is due on the one hand to the fact that the fuel is already homogeneously gaseous in the combustion chamber and not in atomized form as in the case of gasoline and diesel, and on the other hand because the molecular chains only have about half as many carbon atoms in relation to the hydrogen atoms contain as in gasoline and diesel, so when burning with oxygen more water (H 2 O) and less carbon dioxide (CO 2 ) and soot are produced. Both fuels therefore enjoy tax breaks in Germany. With the resolution of the Bundestag on August 27, 2017 on the second amendment law , including the Energy Tax Act , the tax relief for natural gas as a fuel was extended beyond 2018, but the reduced tax rate of currently 13.9 euros / MWh (approx , 18 euros / kg, H-gas quality * ) from January 1, 2024 to December 31, 2026 gradually to 27.33 euros / MWh (approx. 0.35 euros / kg). For comparison: the tax rate for gasoline is currently (2018) around 77.00 euros / MWh. In Germany, natural gas (CNG) can be used for prices between 0.79 euros / kg and 1.27 euros / kg. The average price is 1.06 euros / kg (as of August 2018).

An alternative to pure natural gas is HCNG , a mixture of compressed natural gas and hydrogen that can be used to power any vehicle with a conventional natural gas engine. The same goes for biogas .

Price development

Gas prices peaked in 2008/09. The subsequent shale gas boom in the USA resulted in significantly lower natural gas prices there than in the rest of the world.

At the end of 2015, however, there was a global oversupply. With the increasing possibilities of importing LNG by ship to Europe, there was also a collapse in wholesale prices here.

In 2016, the US company Cheniere Energy started exporting LNG to Europe. The chemical company Ineos has been purchasing ethane from the USA since September 2016 .

Occurrence

In 1844, natural gas was first found in Europe in the area of the Vienna Ostbahnhof. Finds near Wels followed in 1892 . Large gas fields exploited in the 20th and 21st centuries are the Troll field in Norway , the Nord field in Qatar and the Urengoy gas field in Russia. Furthermore, large, undeveloped gas fields are suspected in Iran. Methane in gas hydrates is suspected in large quantities not only in the area of the continental shelf , but also in permafrost in Siberia , Canada and Alaska .

The United States is the country with the highest production rate for natural gas , alongside Russia . In 2006 they produced around 524 billion cubic meters of natural gas. By 1999 they had drilled 94,000 holes in their own country.

Search for deposits

The aim of natural gas exploration is to find natural gas deposits. The focus of interest is on deposit types that can be exploited with relatively little effort using conventional mining methods. Such occurrences are referred to as conventional occurrences . Explorations undertaken by geologists and geophysicists from private or state-owned oil and gas companies therefore focus on identifying geological conditions that make the presence of conventional deposits probable underground.

Conventional natural gas deposits consist of a porous and permeable reservoir rock that is saturated with natural gas and is located below a low-porosity impermeable rock layer, the cap rock. Storage and cover rock must also be part of a geological structure that enables gas to be enriched in amounts that can be mined. Such structures are called natural gas traps . The natural gas cannot escape upwards or to the side and, as it is deep underground, is under high pressure .

The evaluation of satellite or aerial images or the surface geology recorded using classic mapping can be used to identify fossil sedimentary basins. Natural gas leaks (e.g. mud volcanoes ) found in the area may give direct indications of gas deposits in the subsurface. The first more detailed investigations into the geology of the deeper subsurface are often carried out using seismic measurements . Pressure waves (in principle sound ), generated by explosions in shallow boreholes or with the help of vibrators , are sent into the ground. The sound waves are thrown back to the earth's surface by certain layers of the earth, so-called reflectors , where they are recorded by highly sensitive vibration meters, so-called geophones . The depth of individual reflectors results from the time differences between the “launch” of the wave and registration by the geophones. If sound sources and measuring points are arranged in a network on the earth's surface, a three-dimensional seismic model of the subsurface can be created from the data obtained (3D seismic). This model can be used to gain knowledge about the geology of the subsurface, on the basis of which it is determined on which areas of the seismically explored region the further exploration work is concentrated.

Test holes are being drilled at particularly promising locations. The interpretation of the seismic model is compared with the geology actually drilled and refined accordingly. The encounter with gas-saturated sedimentary rocks at a predicted depth then confirms the interpretation of a structure recognizable in the seismic profile as a natural gas trap.

If you are interested in changes in the fluid content of a deposit after the start of production , a so-called 4D seismic analysis can be carried out. Here you can see the changes resulting from the extraction or the remaining stocks of a deposit.

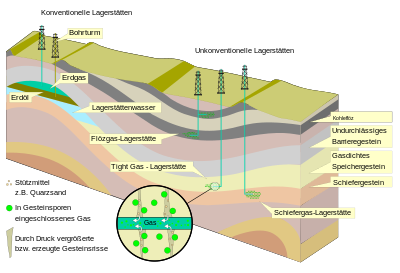

Deposit types

Conventional storage facilities

The type of natural gas reservoir that has so far been developed most frequently are gas deposits in porous and permeable rocks (e.g. sandstones , mass limestone ) beneath low-porosity, impermeable rocks ( mudstones , marl stones , fine-grain limestones). The gas has risen (migrated) in the pore space of the permeable rock from an even greater depth, where further direct ascent is prevented by the impermeable cover rock. A special prerequisite for the formation of a deposit, however, is the existence of geological structures that prevent the gas from migrating to the side below the cover rock and thus enable larger amounts of gas to accumulate in the porous rock, which is then referred to as storage rock. Such structures, which can be of sedimentary or tectonic origin, are called natural gas traps . This can u. a. Be "drowned" fossil reef bodies or the flanks of a salt dome .

Due to its lower density, natural gas occurs very often in the uppermost areas of a conventional oil reservoir. One speaks here of associated ("associated with oil") natural gas . Pure oil deposits without gas are the exception, since gas is always formed in petroleum bedrock and both migrate together into the deposits. The natural gas that arises during oil production is separated and processed separately or, especially in the case of offshore oil production, simply burned off (i.e. burned with a gas flare on site ). Because natural gas has a significantly higher mobility than oil, its migration is easier. Therefore, pure natural gas reservoirs of the conventional type, so-called non-associated natural gas , are relatively common.

Unconventional storage facilities

Deposits that do not correspond to the conventional natural gas trap type and from which gas can usually only be extracted with considerable effort (e.g. by so-called fracking ) are referred to as unconventional . In the USA, 40% of all gas production is already extracted from unconventional deposits.

Coal seam gas

Natural gas, which is also known as mine gas , is also bound in coal seams . Methane is adsorbed to a significant extent by coal on its large internal surface . At greater depths, the higher pressure means that coal can contain proportionally more natural gas and correspondingly more can be pumped through expansion and pumping. Coal seams can also be converted into a natural gas- like fuel gas by underground gasification .

In the US, 10% of natural gas is extracted from coal seams, which was around 40 billion cubic meters in 2002. 11,000 holes were drilled in the United States to develop this type of deposit. In Germany, the natural gas reserves in coal seams are estimated at around 3,000 billion cubic meters. Worldwide, the natural gas reserves in coal seams are estimated at 92,000 to 195,000 billion cubic meters.

Gas hydrates

At high pressure and low temperatures, methane and water form an ice-like solid called methane hydrate . One cubic meter of gas hydrate contains about 164 cubic meters of methane gas. There are considerable deposits in the seabeds of today's continental shelves and slopes, from around 300 meters below sea level, as well as in permafrost . However, the methane probably comes only partially from “leaky” natural gas reservoirs. The other part comes from the activity of microorganisms in the soil or seabed.

Tight gas

" Tight gas " is found in "destroyed" storage rocks (so-called tight gas sands or tight gas carbonates ), i. H. in rocks that were once porous and permeable enough for natural gas to migrate into them. Progressive diagenesis with increased compaction of the storage rock or additional growth of mineral grains led to a significant reduction in the pore space and a loss of pore interconnectivity. Due to the associated loss of permeability, an economically sensible extraction of natural gas from these rocks using conventional methods is impossible.

According to a more general definition of tight gas deposits, the term refers to all non-conventional deposits that are deep underground, but cannot be managed profitably by conventional production methods or do not supply economically viable quantities of natural gas. These definitions not only include natural gas deposits in diagenetically "destroyed" storage rocks, but also shale gas and coal seam gas deposits.

Shale gas

Unlike tight gas in the narrower sense is shale gas ( " shale gas ") not even come to migrate (originally) more porous rock in one, but is still in its host rock, a primary carbon-rich mudstone ( "oil shale" in the broadest Sense).

Aquifer gas

In addition, a considerable amount of natural gas can be dissolved in very deep groundwater layers of an aquifer .

Stocks

According to estimates by the Federal Institute for Geosciences and Raw Materials , the amount of natural gas contained in reservoirs is 819,000 billion cubic meters of natural gas resources and reserves worldwide . There are natural gas reserves, i. H. currently technically and economically recoverable amounts, at 192,000 billion cubic meters. With natural gas production of around 3,200 billion cubic meters per year constant worldwide, this corresponds to a static range of around 60 years. These figures include the joint consideration of conventional and non-conventional natural gas, which has been economically produced for several years, and includes shale gas , coal bed methane (CBM) and natural gas in dense sandstones and carbonates (tight gas) . Tight gas is currently produced predominantly in the United States, although there is no longer any strict distinction from conventional natural gas. In Germany, too, natural gas has been produced from dense sandstones for years and reported together with conventional natural gas. This does not include the resources of aquifer gas and natural gas from gas hydrate, as it is currently still open whether and when this potential can be used commercially. There is a total potential of up to 1,800,000 billion cubic meters here.

For the location of conventional and unconventional deposits of crude oil and natural gas on earth, see also crude oil production .

Natural gas industry

Extraction

Natural gas is obtained by drilling either in pure natural gas fields or as a by-product of oil production . Since the natural gas is usually under high pressure (sometimes around 600 bar), it pumps itself, so to speak, as soon as the reservoir is opened.

Over time, the gas pressure in the reservoir steadily decreases. Exploration nowadays takes place first with three-dimensional physical seismographs, then with geochemical methods and finally with an earth drilling.

Development and extraction on land (onshore)

Unconventional natural gas

Conventional natural gas

When drilling for natural gas, a depth of 4-6 kilometers is often reached, and sometimes up to 10 kilometers for exploratory drilling. There are also drills that can drill into the rock not only vertically, but also diagonally to horizontally (especially developed for offshore drilling). When drilling, the rock must be destroyed and transported upwards, a jacket must protect the drilling cavity.

In the so-called rotary drilling process , the drill bit is located in a jacketed drill rod that is attached to a block and tackle in the derrick (height: 20 to 40 meters).

When drilling, instabilities in the rock and a loss of drilling fluid can occur, which is why strings of pipe (also called casing) must be inserted into the borehole for stabilization . Subsequently, drilling is continued with a smaller diameter.

The borehole diameter decreases with increasing depth (from about 70 cm to 10 cm). An aqueous clay suspension (“drilling mud”) flows in the jacket layer (between the drill pipe and its casing) to cool the drill bit, to stabilize the borehole and to convey the cuttings. In the course of completing the borehole, a sealing sleeve - known as a packer - is placed in the borehole between the production string and the borehole casing (casing) just above the layer carrying natural gas . A fully developed borehole used for extraction together with its above-ground structures is called a probe . These structures specifically include the eruption cross , which closes the bore at its upper end, at the so-called borehole head. It comprises two main valves , one of which is equipped as an automatic safety shut-off valve that automatically blocks the probe in the event of critical operating conditions. From the borehole, the gas is diverted via further slides and the nozzle assembly - usually with an operating pressure of around 70 bar - to the collection point (onshore this is initially a field station from where the gas is forwarded to a central compressor station, where the As a rule, at least a partial preparation and, if necessary, scrap and feed into the network take place).

The drilling costs account for up to 80% of the expenditures for the development costs of a natural gas reservoir.

Induced seismicity

The extraction of conventional natural gas can lead to light, quasi-man-made earthquakes if the stress conditions in the area of the deposit change due to the pressure relief and the accompanying compaction of the deposit rocks to such an extent that movements occur at nearby faults . One example is the Groningen gas field in the province of the same name in the north of the Netherlands, which is generally considered to be aseismic . After nearly 30 years of production from Upper Permian - sandstones in 2600-3200 m depth was there the end of 1991 for the first time recorded seismic activity, their frequency and maximum strength significantly increased in the following years. The strongest earthquakes to date occurred on August 8, 2006 ( M L 3.5), on August 16, 2012 (M L 3.6) as well as on January 8, 2018 and May 22, 2019 (each M L 3.4 ). Although the Dutch government halved the approved production volumes to 24 billion m³ / year in 2016 and reduced it by a further 10% to 21.4 billion m³ / year from October 1, 2017, the costs of repairing the damage ( including cracks in buildings) now amount to around 1.5 billion euros (as of 2018). It is unclear whether the extent of seismic activity is more closely related to the cumulative total flow rate or to the flow rate (flow rate per unit of time). While an increasingly exhausted reservoir rock body appears to be generally more susceptible to seismic reactions, constant low production rates could ensure that stresses in the deposit are relieved mainly only through “ aseismic creeping ”. Another of the strongest induced earthquakes in the Netherlands occurred on September 9, 2001 (M L 3.5) in the Bergenermeer natural gas field near Alkmaar in the province of Noord-Holland, which is much smaller and seismically less active than in Groningen . Seismic activity with magnitudes of M L 2.5 to 3.0 is also known from the natural gas fields in northwest Germany, from the area around Cloppenburg .

Development and extraction in the sea (offshore)

Economically viable natural gas deposits are not only found in the subsurface of the mainland but also in those areas of the upper continental crust that are covered by the sea, the so-called shelves . The first offshore drilling was carried out by the USA in 1947. Later fixed drilling platforms with extendable legs were constructed. Water depths of several hundred meters could be reached.

As a result of increasing interest in the exploration of the outer shelf areas and the continental slope , floating drilling platforms (“Offshore Drilling Units”) and drilling ships were developed. In doing so, the wellhead is shifted to the seabed. With such systems it has been possible to advance to a depth of 3,000 meters.

processing

Drying

Natural gas drying

The drying of natural gas, i.e. H. the removal of water or higher hydrocarbons is an essential process in natural gas processing.

If the drying process is insufficient, methane hydrates can form. The solid methane hydrates can contribute to an extreme pressure drop in the pipeline and damage the valves and pipes. The drying also guarantees a constant calorific value of the gas when it is fed into the public gas network.

The degree of dryness of natural gas is measured using the dew point . As a rule, a pressure dew point below −8 ° C is aimed for.

The following processes, among others, are known for gas drying:

Absorption drying with triethylene glycol

In absorption drying, natural gas is brought into contact with triethylene glycol (TEG) in an absorption column . TEG is very hygroscopic and thus removes the water from the gas.

The two media come into contact in countercurrent . The gas flows from the bottom to the top in the column. In contrast to this, the triethylene glycol is introduced into the column at the top and discharged again at the bottom. A prerequisite for good water absorption is a large contact area between TEG and gas, which is why structured packing is built into the column. The TEG is spread over a wide area in the pack.

The triethylene glycol discharged from the column is reprocessed in a regeneration system. In an evaporator , the absorbed water and, in smaller quantities, hydrocarbons are removed from the triethylene glycol by heating .

The evaporator is heated by hot combustion gases , which are generated in a separately installed combustion chamber . The vapor gases produced during the regeneration are also burned in the combustion chamber . This reduces the need for additional fuel fed in. In addition, the vapor gases do not have to be condensed and disposed of in a laborious manner.

Drying with a molecular sieve

The drying process of gases by means of a molecular sieve usually takes place in different stages:

In a first stage, the pre-drying takes place using heat exchangers or other types of water separators. The gas is cooled and large amounts of water are removed by separators. After this process, however, the residual water content in the gas is still too high to be able to compress it sufficiently and thus liquefy it.

After pre-drying, the gas enters what are known as adsorbers. These are at least two tanks which are filled with a molecular sieve. The gas is first passed through adsorber no. The water vapor is absorbed (adsorbed) by the molecular sieve. This adsorption cycle can take up to 12 hours or more. The gas flow is then passed through adsorber no. 2 and adsorber no. 1 “goes” into the regeneration phase. During regeneration, hot air, nitrogen or natural gas with a temperature of approx. 280 ° C is pressed through the adsorber. This releases the water vapor molecules retained by the molecular sieve and transports them out of the tank. The molecular sieve is then cooled for several minutes to hours. An adsorption and regeneration phase is called a cycle.

A dew point of down to −110 ° C can be reached at the gas outlet.

The molecular sieves used in natural gas drying are specially developed for a wide variety of gas compositions. Often not only water molecules but also hydrogen sulfide or hydrocarbons have to be removed from the gas. In most cases, a 4A molecular sieve (with a pore opening of 4 Å in diameter) is used. There are also situations for which a combination of different types is used.

Separation of carbon dioxide and hydrogen sulfide

The separation of carbon dioxide and hydrogen sulfide takes place chemically or physically. The two gases can be bound together with a base such as N-methyl-pyrrolidone (Purisol process) in a high-boiling solvent.

In the physical separation, for example the sulfinol process, a high-boiling polar organic liquid containing some water is used. The sulfinol process uses a mixture of diisopropanolamine (DIPA), tetrahydrothiophene dioxide (sulfolane) and water as the solvent .

The hydrogen sulfide from the natural gas is converted to sulfur under high heat with oxygen ( Claus process ).

Separation of nitrogen

Nitrogen and helium can be separated from natural gas by means of low-temperature separation. A gas stream enriched with nitrogen rises upwards in a high pressure separation apparatus, methane gas flows to the bottom of the column. This process step can be coupled with the production of liquefied natural gas (LNG).

Radioactive waste

In December 2009 it became known to the public that millions of tons of radioactive residues are produced annually in the production of oil and natural gas , for the majority of which there is no evidence for disposal. Sludge and wastewater pumped to the earth's surface in the course of extraction contain NORM substances (Naturally Occurring radioactive material), including the highly toxic and extremely long-lived radium 226 and polonium 210. The specific activity of the waste is between 0.1 and 15,000 Becquerel (Bq) per gram. In Germany, where around 1,000 to 2,000 tons of dry matter are produced each year, according to the radiation protection ordinance of 2001, the material requires monitoring from a Bq per gram and must be disposed of separately. The implementation of this regulation was left to the responsibility of the industry, which ultimately meant that the waste was disposed of carelessly and improperly for decades. Cases are documented in which waste with an average of 40 Bq / g was stored on company premises without any labeling and should not be specially labeled for transport.

In countries with larger amounts of oil or gas extracted, significantly more waste is generated than in Germany, but there is no independent, continuous and seamless recording and monitoring of contaminated residues from oil and gas production in any country. The industry deals with the material differently: In Kazakhstan , large areas of land are contaminated by this waste, in Great Britain the radioactive residues are discharged into the North Sea. In the United States , almost every state is experiencing increasing problems due to radioactive contamination from oil production. In Martha, a community in Kentucky , Ashland Inc. has sold thousands of contaminated production pipes to farmers, kindergartens and schools without notifying them of the contamination. Up to 1,100 micro-X-rays per hour were measured, so that the primary school and some residential buildings had to be evacuated immediately after the radiation was discovered.

transport

Natural gas is mainly transported over long distances via pipelines (hence the term long-distance gas ). Significant pipelines for the connection of Western Europe, most of whose natural gas is obtained from Russia, include Nord Stream (North European Gas Pipeline), the Soyuz Pipeline and Yamal-Europe natural gas pipeline .

Natural gas can be prepared by physical-technological method compressed (CNG Compressed Natural Gas ) or in the liquid aggregate state ( LNG , liquefied natural gas ) to be transferred. What these processes have in common (see fuel for motor vehicles ) is a reduction in volume or an increase in density , which means that larger quantities of natural gas can be stored in a smaller space or transported per unit of time.

Pipelines

The pressure in gas pipes varies depending on the transport and distribution.

The steel long-distance transport pipelines on the mainland have a nominal diameter of 600 to 1400 millimeters, are under a nominal pressure of around 75 to 84 bar, and are usually laid around one meter underground. A compressor station has to increase the pressure every 100 to 150 kilometers. Further transport of natural gas can - depending on the design, altitude and flow rate of a pipe - lead to considerable energy consumption by pumps. At 4,700 kilometers, around 10% of the energy in the natural gas has to be used to operate the pump. In order to limit the dangers of leaks, which could allow an unhindered gas escape, slide valves are also installed in a pipeline at certain intervals. The pipe pressure of the gas network can be remotely monitored in a control center. This network is operated by the transmission system operators.

There is a special, denser network system operated by regional operators for the regional distribution of natural gas, with a pipeline pressure of around 16 bar. There is a third network for the transport of natural gas to the regional municipalities, which only has a natural gas pressure below 1 bar, and for private households an overpressure of only 20 mbar. Up to a pressure of 10 bar, pipes made of plastic ( polyethylene ) are common today for gas lines .

In Germany, the high-pressure natural gas network was around 50,000 kilometers long in 2002, while the network with low-pressure pipes to the house connections was 370,000 kilometers long.

For the construction and operation of natural gas networks, depending on the subsoil (rock, sand) and geography (crossing of rivers with culverts, railway lines, motorways, etc.), large amounts must be raised. The procurement or market value of a natural gas network is difficult to estimate and also depends on the business model (future earnings value).

The five natural gas transit pipelines in Austria had a nominal pressure of 70 bar throughout and the following nominal diameters in 2006: Trans Austria gas pipeline with three parallel strands (about 380 kilometers long) with 900 to 1,050 millimeters, West Austria gas pipeline (245 kilometers) 800 millimeters, (shorter than 100 km) Hungarian-Austria-Gasleitung and Penta-West 700 mm and South-East gas line 500 mm. TAG received a second tube (around 2006 at Wildon), TAG from 1970 received new compressors in Neustift and Baumgarten in 2009 + 2011 .

LNG transport ships

For shipping, the natural gas is liquefied by cooling it to −160 ° C ( Liquefied Natural Gas , LNG ). The currently (2014) largest LNG tankers of the Q-Max class can transport over 266,000 m³ of LNG. There are two types of LNG tanker: the spherical tanker and the membrane tanker. A total of 130 LNG tankers had been constructed by the year 2000.

From 4,000 kilometers by land or 2,000 kilometers by sea, this type of transport is more economical than transport via a pipeline system.

Conversion into synthetic liquid fuels

Because mineral oils such as gasoline and diesel do not require pressure vessels for storage and transport, the chemical-technical conversion into long-chain hydrocarbons that are liquid at room temperature (so-called GtL process ) is one way of converting natural gas into a relatively easy-to-use and space-saving form. Such synthetic mineral oils are free of sulfur and heavy metals and therefore also more environmentally friendly than mineral oils made from natural crude oil . The companies Sasol (South Africa) and Shell (Malaysia) produced a synthetic mineral oil from natural gas as early as 1997, which was used as a diesel additive. The basis was the conversion of methane with oxygen to synthesis gas (2 CH 4 + O 2 → 2 CO + 4 H 2 ). Synthesis gas can be converted into synthetic mineral oils under high pressure and high temperatures using the Fischer-Tropsch process .

Since the process required high temperatures, pressures and pure oxygen, attempts were soon made to improve the reaction conditions for the conversion. The Syntroleum Company (in Tulsa, USA) developed a process that produced good crude oil yields using air instead of pure oxygen . The lowest possible conversion temperatures are decisive in terms of costs. A variety of catalysts have been tried for such conversion. Companies would also like to achieve the conversion of natural gas in a single reaction step.

In 1999, Pennsylvania State University had developed a process for converting methane into methanol at less than 100 ° C using a catalyst.

storage

Underground natural gas storage facilities were built to compensate for load fluctuations in the natural gas supply. A BDEW spokesman announced that there are 46 underground gas storage facilities in Germany. Their absorption capacity is almost 20 billion cubic meters of working gas . That corresponds to almost a quarter of the natural gas consumed in Germany in 2007. In Austria, the capacity is 5 billion cubic meters and is therefore even higher in percentage terms.

Underground salt caverns are sometimes used as storage locations for natural gas. To create the storage cavity, water is pumped through a borehole into a geological salt formation. The salt dissolves in a controlled process and the resulting brine is drained through the same borehole. However, emptied oil and gas reservoirs can also serve as so-called pore stores. So-called tube accumulators with 50 to 100 bar have short-term capacity , which are laid a few meters deep in the ground in a meandering manner, for example can be part of a disused natural gas pipeline.

The significantly smaller surface gas storage facilities are mainly used for daily fluctuations in demand. Instead of the previous tower-high gasometers (mostly telescopic and disk gas containers ), high-pressure spherical gas containers are now used, which are operated at around 10 bar overpressure.

care

World subsidies

The net world production of natural gas (natural gas) minus back-pressed and flared gas was around 3,680.4 billion cubic meters in 2017 , of which the USA is 20.0% (corresponds to 734.5 billion cubic meters of natural gas) and Russia is 17.3 % (635.6 billion cubic meters) world market share the main producing countries. In 2010, Russia was the last time before the USA in terms of natural gas production. Among the producing countries, Iran ranks third with 6.1% (223.9 billion cubic meters).

With a slight upward trend, natural gas thus covered around 24% of global energy consumption in 2017 . With 739.5 billion cubic meters, which corresponds to 20.1% of the world's natural gas consumption, the USA also tops the list of consumers. Consumption there is around five billion cubic meters higher than in-house production. Russia recently consumed 424.8 billion cubic meters of natural gas (11.6% of global natural gas consumption), making it a net natural gas producer. In third place among the natural gas consumers, China ranks with 240.4 billion cubic meters, which corresponds to 6.6% of world consumption.

Situation in Germany

care

By the early 1980s, the gas supply in most West German cities had been switched from town gas , which is toxic due to the high content of carbon monoxide , to natural gas. This was possible without major modifications. In the area of the former GDR, the changeover was mainly carried out in the 1990s.

| German final energy consumption of natural gas | ||

|---|---|---|

| year | in petajoules | in billions of cubic meters

(1 m³ corresponds to 35.169 MJ calorific value ) |

| 2000 | 2,204.0 | 62.67 |

| 2002 | 2,290.2 | 65.12 |

| 2004 | 2,216.7 | 63.03 |

| 2006 | 2,189.1 | 62.25 |

| 2008 | 2,176.9 | 61.90 |

| 2010 | 2,247.3 | 63.90 |

| 2011 | 2,038.2 | 57.96 |

| 2012 | 2,122.7 | 60.36 |

| 2013 | 2,184.3 | 62.11 |

| 2014 | 1,956.5 | 55.63 |

| 2015 | 2.056.5 | 58.48 |

| 2016 | 2,130.5 | 60.58 |

| 2017 | 2,149.3 | 61.11 |

| 2018 | 2,082.7 | 59.22 |

For more than 25 years there have been considerations to build an LNG terminal for liquefied natural gas tankers near Wilhelmshaven in order to reduce the dependence on imports via pipelines.

Around 18.6 billion cubic meters of natural gas are stored in underground storage facilities to cover peaks and to compensate for short-term import disruptions and fluctuations in demand .

The use of natural gas is subject to a natural gas tax , the standard rate of which is currently € 5.50 per megawatt hour (that's 0.55 cents per kWh).

The oil price link plays a major role in the formation of prices for natural gas . However, according to a widespread opinion, the cartel of gas price formation based on the industry-internal agreement on an oil price link violates European and German antitrust law. The Federal Court of Justice (BGH) ruled on March 24, 2010 that gas suppliers may no longer link their prices solely to the development of the oil price.

The Federal Office of Economics and Export Control ( BAFA ) registers the import and export prices of natural gas on a monthly basis, and the quantities purchased for individual supplier countries are also recorded. Between 1991 and 1999 the import price for natural gas per terajoule averaged between € 1,700 and € 2,200. Between 2001 and 2004, the natural gas import price per terajoule was between € 3,200 and € 4,200. In 2006, the natural gas import price per terajoule rose temporarily to over € 6,000. In November 2008 the import price for natural gas was € 8,748 per terajoule, and in September 2009 € 4,671. Price jumps for natural gas are not transparent for consumers.

origin

The origin of the imported natural gas may no longer be published since 2015, this is due to the provisions of Section 16 of the Federal Statistics Act in conjunction with Section 11 Paragraphs 2 and 5 of the Foreign Trade Act . Because the transfer of the data could affect individual companies in their trade and business secrets.

The last available status of the Federal Ministry for Economic Affairs and Energy from 2015 is composed as follows:

34.7% of the imported natural gas came from the Russian Federation, 34.1% from Norway and 28.8% from the Netherlands. The remaining 2.5% come from “other countries”. These are the transfer countries from which the natural gas comes to Germany and not the producing country. For example, some of the natural gas from the Netherlands comes from the United Kingdom as liquefied gas before it is sent to Germany.

German natural gas company

The world's largest natural gas producer based in Germany is the BASF subsidiary Wintershall . The largest natural gas supply companies in Germany are E.ON Ruhrgas (Essen), RWE Energy (Dortmund), VNG - Verbundnetz Gas (Leipzig), Wingas (Kassel), Shell (Hamburg) and ExxonMobil (Hanover). The transport (pipelines) is ensured by so-called transmission system operators , including Open Grid Europe (Essen), bayernets (Munich), Ontras (Leipzig), Gascade (Kassel) and Terranets BW (Stuttgart).

Distribution to end consumers is carried out by around 700 gas supply companies, in particular municipal utilities. E.ON Ruhrgas acquires most of the natural gas it purchases from the Russian company Gazprom as well as from the Dutch Gasunie and the Norwegian producers.

Measurement

The measurement at the end customer is volumetric, i.e. by volume measurement. In order to deduce the amount of gas (mass) from the volume, one needs the density, i.e. the absolute pressure, and the temperature of the gas. This is why there is often a pressure regulator directly in front of the so-called gas meter , which regulates the overpressure in relation to the external pressure in a last stage. In pipeline networks , which are often operated with downwardly graduated pressure levels, fluctuating consumption rates and different pipeline volumes cause an incalculable pressure drop, which is compensated for by the pressure regulator. The temperature fluctuation is kept as low as possible by installing it inside a building.

Pressure regulators on the gas meter must be calibrated, just like the volume measuring device itself. The external air pressure as a reference may be taken into account according to the sea level of the individual meter or a flat rate for the location or district (100 m altitude difference makes up a little less than 1% gas pressure difference, meteorological fluctuations will not be considered). The energy content per kg of gas is then determined, adjusted by mixing and taken into account for billing purposes.

Gas shut-off

In international gas trading, gas shut-offs or reductions in delivery quantities (rates) are the subject of political negotiations.

Market area conversion

L-gas from German and Dutch production currently serves around 30% of the German natural gas market. However, the production volumes are declining, so that in the following years until probably 2030 all affected network areas will have to be converted to H-gas, which is available in the long term. This measure serves to ensure security of supply in the federal states of Bremen, Lower Saxony, North Rhine-Westphalia, Saxony-Anhalt, Hesse and Rhineland-Palatinate.

In the course of this so-called market area conversion , the devices operated with natural gas must be adapted to the use of H-gas for all consumers. This applies equally to private households and companies. In the run-up to the actual adjustments, a full survey of all gas appliances - such as gas stoves and boilers - takes place in the respective network area in order to obtain an overview of the total available gas appliances.

The costs incurred when adapting the gas devices are determined by regulating the network charges in accordance with §§ 21 ff. EnWG passed on to all end consumers (allocation of costs). The network charge regulation takes into account in particular the fact that the operation of a gas supply network represents a natural monopoly which, without statutory regulation, could freely determine the prices for network use and thus set excessively high.

Situation in Austria

Natural gas was added to town gas in Austria as early as 1943 . In the cities (e.g. Baden, Stockerau, Vienna, Wiener Neustadt), the conversion from town gas to natural gas took place from the end of the 1960s through to the 1980s.

| year | Austrian natural gas import TJ |

|---|---|

| 2000 | 248.064 |

| 2005 | 373.822 |

| 2010 | 474.049 |

| 2011 | 510.953 |

| 2012 | 541.128 |

| 2013 | 396,671 |

| 2014 | 386,748 |

| 2015 | 438.718 |

End consumers, in particular private households, will have their gas supply blocked by the gas supplier in the event of default of payment after at least two reminders - in order to enable them to be switched on again quickly, but not before public holidays. In 2013, 8,457 private households in Austria, 6,081 of them in Vienna, were "turned off" by the regulatory authority E-Control for the first time in May 2014 due to the Gas Monitoring Ordinance . Numbers of power cuts for the same reason are usually "put into boxes" by the utilities.

Ecological aspects

Due to the low level of impurities, natural gas generally burns cleaner than other fossil fuels . Due to the higher hydrogen / carbon ratio, burning natural gas produces up to 25% less carbon dioxide than heating oil. Nevertheless, the extraction, transport, processing and combustion of natural gas contribute to the release of the greenhouse gases methane and carbon dioxide , especially if it is so-called shale gas (see also greenhouse gas emissions from fracking ).

It is ecologically and economically nonsensical if natural gas, as a by-product of oil production, cannot be profitably sold or pumped back into the earth, but has to be flared . Various flare-down programs in the oil industry are intended to reduce flaring and the natural gas to be processed and used in a controlled, cleaner way, replacing other energy sources. This brings about a considerable improvement in the global ecological balance and is therefore promoted by tax advantages. If natural gas is no longer available in sufficient quantities, the sustainability of investments in regional natural gas networks can be guaranteed through increasing production and admixture of biogas .

Components of the natural gas that have escaped through leaks in conveyor systems and pipelines either go directly into the earth's atmosphere or some components dissolve in the seawater if the gas escapes from submarine pipes. If the depth is sufficient, the pressure is high and the temperature is sufficiently low, the methane content of the natural gas can be deposited as solid methane hydrate on the sea floor.

The extraction of unconventional natural gas by means of hydraulic fracturing is associated with some additional environmental risks, in particular with regard to the chemicals added to the fracking fluids and the escape of harmful substances contained in natural gas from flowback and reservoir water stored in open tanks. More problematic, however, is the sharp increase in natural gas production in the area as a result of the fracking boom, as can be observed from the year 2000, especially in the USA. This leads to an increase in the environmental pollution generally associated with natural gas production.

Security aspects

Due to its explosiveness, natural gas harbors certain risk of accidents. B. in households of accidents up to catastrophic events (e.g. gas explosion from Chuandongbei , gas explosion from Belgium ).

On March 25, 2012, it was discovered that an unknown leak on the Total Group's Elgin PUQ gas (and oil) production platform in the North Sea was leaking gas under water. First, according to the operator, 200,000 cubic meters of gas flowed out of the leak 25 meters above the water level into the open, later the amount was reduced to around a third. There is a risk of fire and explosion from gas that has come into the air and, due to the toxicity of the hydrogen sulfide contained in the gas, safety zones of up to 5.6 km radius have been established for ships and aircraft and neighboring platforms have been evacuated. 50 days later, in mid-April 2012, the company announced that the leak had closed again.

See also

- Natural gas / tables and graphs

- Take-or-pay contract

- Synthetic natural gas

- Journal of Natural Gas Chemistry

literature

- Holger Kulke: The energy source natural gas. Earth sciences. Vol. 12, No. 2, 1994, pp. 41-47, doi: 10.2312 / geoswissenschaften . 1994.12.41 .

- Stefan Ueberhorst: Natural gas as energy source - exploration, production, supply. Library of Technology, Volume 102, Verlag Moderne Industrien, Landsberg 1994, 2nd edition, ISBN 3-478-93105-3 .

- Günther Cerbe: Basics of gas technology - gas procurement, gas distribution, gas use. Hanser Verlag, Munich / Vienna 2004, 6th edition, ISBN 3-446-22803-9 .

- Federal Association of the German Gas and Water Management, BGW: The natural gas supply of the future, information and background information on the German natural gas market; 2006 PDF file

Web links

- Annual review "Petroleum and natural gas in the Federal Republic of Germany" , each published in the journal Erdöl Erdgas Kohlen (list with article download links from 2002 on the LBEG website )

- Federal Association of Energy and Water Management V. (BDEW). 2010, accessed July 30, 2010 .

- Wirtschaftsverband Erdöl- und Erdgasgewinnung e. V.

- Erdgas.at - Austrian Association of Gas and Heat Supply Companies

- Erdgas.ch - Association of the Swiss Gas Industry

- DVGW German Association for Gas and Water V. / Technical-Scientific Association

- SPIEGEL ONLINE: Topic page on unconventional gas extraction

- Federal Institute for Geosciences and Raw Materials

- W. Wagner, O. Kunz: The whole (thermodynamic) truth is in a formula. Natural gas equation of state as an international standard , PDF file

Individual evidence

- ↑ Livia Beier, Christian Bantle (Red.): How is Germany heating? BDEW study on the heating market. Federal Association of Energy and Water Management V., Berlin 2015 ( PDF 3.3 MB).

- ↑ for some examples in Austria see Ute Kutschera and 32 other authors: Cross-media environmental control in selected areas. Monographs, M-168. Federal Environment Agency, Vienna 2004 ( PDF 19 MB).

- ↑ Use of natural gas for buses , press release from EVN AG of December 18, 2006.

- ↑ Natural Gas Composition and Specifications. John A. Dutton e-Education Institute, PennState College of Earth and Mineral Sciences, (accessed March 31, 2018)

- ↑ Overview of Natural Gas - Background. naturalgas.org (accessed March 31, 2018)

- ↑ Kulke: The energy carrier natural gas. 1994 (see literature ), p. 42 ff.

- ↑ a b S. Ueberhorst: Energy carrier natural gas. 1994, p. 50.

- ↑ Alberto de Angelis: Natural gas removal of hydrogen sulphide and mercaptans. Applied Catalysis B: Environmental. Vol. 113-114, 2012, pp. 37-42, doi: 10.1016 / j.apcatb.2011.11.026

- ↑ Natural gas components ( memento from January 26, 2016 in the Internet Archive ).

- ↑ Ullmann's Encyclopedia of Technical Chemistry, 5th Edition, Vol.A17, p. 74 ff.

- ↑ Technical rules - Worksheet G 260: Gas quality. DVGW German Association for Gas and Water V., Bonn 2000 ( PDF file ( page no longer available , search in web archives ); 1.0 MB), p. 8 f.

- ↑ Gas families according to DVGW worksheet G 260 (gas quality). (PDF) Retrieved February 9, 2020 .

- ↑ Ströbele, Pfaffenberger and Heuterkes (2013): Energy Industry . Introduction to Energy and Politics , 3rd edition, p. 149.

- ↑ Author collective: Gas installation: Tips for practice. Published by the working group for economical and environmentally friendly energy consumption e. V. (ASUE) and the German Association for Gas and Water. V. (DVWG), Berlin 2010 ( PDF file ; 2.2 MB), p. 14 f

- ↑ Lianyong Feng, Yan Hu, Charles AS Hall, Jianliang Wang: The Chinese Oil Industry: History and Future. Springer, New York 2013, ISBN 978-1-4419-9409-7 , p. 2 f.

- ^ A b Chi-Jen Yang, Yipei Zhou, Robert B. Jackson: China's fuel gas sector: History, current status, and future prospects. Utilities Policy. Vol. 28, 2014, pp. 12–21, doi: 10.1016 / j.jup.2013.11.002 (alternative full text access : jacksonlab.stanford.edu ), p. 14

- ^ A b Hans Ulrich Vogel: The Great Well of China. Scientific American. Vol. 268, No. 6, 1993, pp. 116-121, JSTOR

- ↑ Natural Gas is King in Pittsburgh , American Oil and Natural Gas Historical Society, accessed July 27, 2014.

- ↑ a b Encyclopedia of Natural Sciences and Technology , Zweiburgenverlag Weinheim 1981, Volume EJ, keyword: Erdgas, p. 1232 ff.

- ↑ Craig Morris: Future energies, The turn to the sustainable energy system , Heise Zeitschriftenverlag 2006, p. 91 ff., ISBN 3-936931-26-7 .

- ^ Complete edition of the energy data - data collection of the BMWI. xlsx document. In: bmwi.de. Federal Ministry for Economic Affairs and Energy, June 22, 2020, accessed on August 25, 2020 .

- ↑ Swiss overall energy statistics 2018. Federal Office of Energy SFOE, July 10, 2019, accessed on August 25, 2020 .

- ↑ a b c d e Landolt Börnstein: New Series VIII , 3A, Natural Gas Exploitation Technologies, Springer, 2002, p. 40 ff. Doi : 10.1007 / 10696439_5

- ↑ Power generation | Energy Charts. Retrieved October 1, 2019 .

- ↑ Second law amending the Energy Tax Law and the Electricity Tax Law. Federal Law Gazette (BGBl) I 2017/60, September 4, 2017, pp. 3299–3315, online , for changes to Section 2 (2) relating to natural gas as a fuel, see p. 3300

- ↑ a b c Continued funding for LPG. ADAC website, Info, Test & Advice section , accessed on August 5, 2018

- ↑ LPG and CNG filling station directory for Germany. Accessed August 5, 2018.

- ↑ KfW : Into the future with gas , November 30, 2015.

- ^ A b Michael McDonald: European Natural Gas Prices Collapse. In: OilPrice.com. May 17, 2016. Retrieved October 25, 2016 .

- ^ First US shale gas arrives at Ineos plant in Scotland . In: BBC News . September 28, 2016 ( bbc.com ).

- ↑ a b c d e f g Winnacker, Küchler: Chemische Technik , Volume 4, Energieträger, 5th edition, pp. 13 ff., ISBN 3-527-30769-9 .

- ↑ Natural gas from Germany: Treasure hunt in the slate. Spiegel Online, April 12, 2010, accessed April 12, 2010 .

- ↑ Jan Willmroth: Energy: No matter what happens, fracking will stay . In: Süddeutsche Zeitung . February 11, 2016 ( sueddeutsche.de ).

- ↑ Karen E. Higgs, Horst Zwingmann, Agnes G. Reyes, Rob H. Funnell: Diagenesis, Porosity Evolution, and Petroleum Emplacement in Tight Gas Reservoirs, Taranaki Basin, New Zealand. Journal of Sedimentary Research. Vol. 77, No. 12, 2007, pp. 1003-1025, doi: 10.2110 / jsr.2007.095 .

- ↑ The best definition of tight gas reservoir is “a reservoir that cannot be produced at economic flow rates nor recover economic volumes of natural gas unless the well is stimulated by a large hydraulic fracture treatment, by a horizontal wellbore, or by use of multilateral wellbores . ” Stephen A. Holditch: Tight Gas Sands. Journal of Petroleum Technology. June 2006, pp. 84-90.

- ↑ Gas from oil shale fields is turning natural gas markets upside down. In: VDI-Nachrichten. VDI Verlag GmbH, March 12, 2010, accessed on August 2, 2010 .

- ↑ a b Short study - Reserves, resources and availability of energy raw materials 2011. (PDF file; 9.0 MB) Federal Institute for Geosciences and Natural Resources , November 2011, accessed on October 22, 2012 .

- ↑ a b K. van Thienen-Visser, JN Breunese: Induced seismicity of the Groningen gas field: History and recent developments. In: The Leading Edge. Vol. 34, No. 6, 2015, pp. 664-671, doi: 10.1190 / tle34060664.1

- ^ A b c Charles Vlek: Rise and reduction of induced earthquakes in the Groningen gas field, 1991-2018: statistical trends, social impacts, and policy change. In: Environmental Earth Sciences. Vol. 78, No. 3, 2019, Item No. 59, doi: 10.1007 / s12665-019-8051-4

- ↑ Zware aardbeving in Groningse Westerwijtwerd. “Nieuwsbericht” on the website of the Koninklijk Nederlands Meteorologische Instituut (KNMI), May 22, 2019

- ↑ Thorsten Czechanowsky: The Netherlands cut L-gas production. In: energate messenger , April 19, 2017

- ↑ Machiel Mulder, Peter Perey: Concluding remarks. S. 67–68 in: Machiel Mulder, Peter Perey (ed.): Gas production and earthquakes in Groningen - reflection on economic and social consequences. Center for Energy Economics Research (CEER) Policy Papers, No. 3. Department of Economics and Business, University of Groningen, 2018 ( PDF 1.8 MB; complete booklet)

- ↑ B. Dost, HW Haak: Natural and induced seismicity. Pp. 223-239 in: Th. E. Wong, DAJ Batjes, J. de Jager (Ed.): Geology of the Netherlands. Koninklijk Nederlandse Akademie van Wetenschappen, Amsterdam 2007, ISBN 978-9-069-84481-7 , p. 232

- ↑ a b Radiant waste from oil and gas. In: tagesschau.de. December 7, 2009; archived from the original on December 8, 2009 ; Retrieved February 6, 2010 .

- ↑ a b Unknown hazard - radioactive waste from the oil and gas industry. In: Deutschlandfunk. February 5, 2010, accessed February 6, 2010 .

- ↑ Radioactive Residue - Oil production problems affect Kentucky residents. In: Deutschlandfunk. March 9, 2010, accessed March 13, 2010 .

- ^ Christoph Edler: The Austrian gas network. Bachelor thesis, Vienna University of Technology, 2013 ( PDF file ; 15 MB) p. 37 ff.

- ↑ http://www.bto-consulting.com/4media/download/MarineServiceBTOConference2015.pdf

- ^ Safaa A. Fouda: Natural gas liquefaction - crude oil from the chemistry kit. Spectrum of Sciences, 4/1999, p. 92.

- ^ Minister wants gas reserve for Germany , Ärzte Zeitung , September 1, 2008.

- ↑ a b BP Statistical Review of World Energy 2018. (PDF file) BP , June 2018, accessed July 27, 2018 .

- ↑ a b Complete edition of the energy data - data collection of the BMWI. In: bmwi.de. Federal Ministry for Economic Affairs and Energy, June 22, 2020, accessed on August 12, 2020 (Table 17 "Volume and final energy consumption of natural gas").

- ↑ BGH, judgment of March 24, 2010 , Az.VIII ZR 178/08, full text and press release No. 61/2010 of March 24, 2010.

- ↑ Written question to the Federal Government in January 2019, question no.180. Federal Ministry for Economic Affairs and Energy, January 23, 2019, accessed on August 25, 2020 .

- ↑ Monitoring report 2019. Bundeskartellamt, Bundesnetzagentur, January 13, 2020, p. 361 , accessed on August 25, 2020 .

- ↑ Wintershall sells Norwegian gas fields. Handelsblatt, August 15, 2015.

- ↑ Market area conversion , DVGW , accessed on February 7, 2016.

- ^ Federal Statistical Office Austria

- ↑ 6,081 Viennese the gas was turned off , ORF.at from May 26, 2014.

- ↑ Gas escapes uncontrolled , ORF.at from March 27, 2012.

- ↑ "Elgin" -Gasleck is stuffed Der Spiegel of 16 April 2012 found.