Combined gas and steam power plant

A gas and steam combined cycle power plant or gas and steam turbine power plant ( combined cycle power plant for short ) is a power plant in which the waste heat from a gas turbine power plant is used in a steam power plant. The exhaust gases from the turbine serve as a heat source for a downstream waste heat boiler , which in turn acts as a steam generator for the steam turbine .

With this combined mode of operation, the two thermodynamic cycle processes together achieve a higher degree of efficiency than with separate gas turbines in open operation and conventionally fired steam power plants. Combined power plants with electrical efficiencies of up to 63.08% are among the most efficient conventional power plants (see gas engine ). With conventionally produced natural gas, the greenhouse gas emissions of combined cycle power plants are around 450 g CO 2 -eq / kWh (carbon dioxide equivalent).

In addition, the integration of (thermal) solar energy by means of solar collectors is possible, so that fuel can be saved compared to conventional power plants at suitable locations with high solar radiation. A first solar hybrid combined cycle power plant, the Hassi R'Mel power plant, went into operation in Algeria in 2011 .

Combined power plants can be used very flexibly in power plant management : Thanks to short start times and the possibility of rapid load changes , they are ideal medium- load power plants. These power plants are primarily operated in the medium load range and, if necessary, even in the peak current range. Operation as a base load power plant is also possible, but this is not economical in Germany due to the price of gas and is therefore not common.

nomenclature

The abbreviation “ GUD power plant” was a protected name of the Siemens company for a long time ; but not since the end of September 2009. Even when GUD was still a brand, this name was often used as a generic term. This type of power plant is generally referred to as a combined cycle power plant , with the risk of being confused with, for example, combined heat and power . Other manufacturer names are, for example, Steam and gas (STEAG) from General Electric or Kombeanlage (KA) from Alstom . In the English-speaking world, one speaks of Combined Cycle Power Plant (CCPP) or Combined Cycle Gas Turbine (CCGT) .

Mode of action

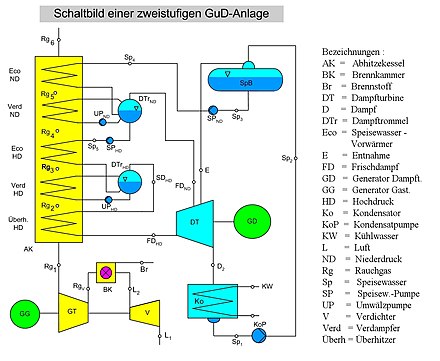

In the combined cycle power plant , electricity is one to four gas turbines and one steam turbine produced, wherein either each turbine respectively a generator driving (multi-shaft system, engl. Multi adhesive) or a gas turbine to the steam turbine (uncoupled with a self-timed coupling ) on a common shaft the generator (Single shaft system, English singles liability). The hot exhaust gases from the gas turbines are used in a waste heat steam boiler to generate water vapor . The steam is then expanded using a conventional steam turbine process. Approx. 2/3 of the electrical power comes from the gas turbine and 1/3 from the steam process.

If, in addition to using the exhaust gas heat of the gas turbine, the steam output and thus the electrical output of the steam turbine is increased by additional firing (additional firing), this is called a combined process. Gaseous or liquid fuels such as natural gas , biogas or heating oil are used to operate the gas turbine . Other fuels can also be used to operate the burner in the steam boiler.

power

The (electrical) power of combined cycle plants is in the range between 80 and 845 (e.g. Irsching ) megawatts per unit gas turbine / steam turbine, whereby a power plant can consist of several units. In comparison, a block of a nuclear power plant has an output between 400 and 1600 MWel.

Efficiency

The extraordinarily high efficiency of the combined cycle power plant is achieved by the fact that the heat from the flue gas is fed into the process at a high temperature level. The stoichiometric (λ = 1) combustion temperature of natural gas with air at normal pressure is approx. 2200 ° C. However, excess air reduces the inlet temperatures of the gas turbines. The maximum possible gas inlet temperature today is 1600 ° C. The outlet temperatures are around 650 ° C. Depending on the output, the gas turbines have an efficiency (electrical output based on supplied heat) of 35% (10 MW el ) to over 40% (100 MW el ).

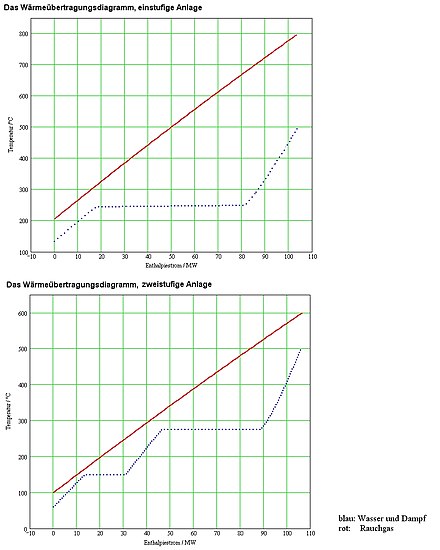

The exhaust gas is used in a waste heat boiler to generate superheated steam with a temperature> 500 ° C. However, a large part of the heat (enthalpy difference) is required for evaporation at the pressure-dependent saturated steam temperature . At 100 bar, for example, this is only 311 ° C. This means that in a system with only one vapor pressure stage (see first circuit diagram on the right) at the entry of the flue gas into the evaporator, the temperature difference between flue gas and water is very large, and the exergy losses during heat transfer are correspondingly high . If the flue gas has cooled down to a few degrees above the evaporation temperature, the remaining heat content can only be used to preheat the feed water (compare heat transfer diagram and Ts diagram on the right). The computationally active original file, from which the diagram shown on the right is taken, calculates an efficiency of 52% based on the calorific value. In relation to the calorific value , the efficiency is 52% / 1.11 = 47%.

The water-side switching of the boiler can be very different depending on the operational requirements. In addition to the forced circulation boilers shown here, natural circulation boilers and forced flow boilers (Benson boilers ) are also common.

To avoid higher exergy losses, that is to say to improve the efficiency, several pressure stages are used. The second circuit diagram shows a two-stage system. The feed water is either taken from the feed water tank with separate feed water pumps and fed to two separate feed water preheaters , or - as in the figure - the pressure stages are connected in series. The evaporation and overheating thus take place at different temperature levels.

The state of the art in combined cycle power plants for pure electricity generation, i.e. without further use of the waste heat for heating purposes or as process heat, is the three-pressure process with reheating. A so-called F-class gas turbine is usually used here. The electrical output of these systems is around 400 MW. The pressures are around 130 bar (high pressure), 30 bar (medium pressure) and 8 bar (low pressure). The high pressure steam is superheated to around 570 ° C. After the expansion in the high-pressure section of the turbine, the steam is returned to the boiler, mixed with the medium-pressure steam and superheated again to around 570 ° C. In theory, even more pressure levels would be conceivable for better adaptation of the steam characteristic to that of the flue gas, but the additional investment outlay is then too high in relation to the thermal improvement. The three-pressure process with reheating is currently the most economical.

At the E.ON location in Irsching, a test field was created for the world's largest and most powerful SGT5-8000H (375 MW) gas turbine , which was newly developed by Siemens Power Generation. After completion of the test phase, the gas turbine was integrated into a modern CCGT with an overall efficiency of 60%.

Development of top efficiency

- On May 11, 2011, power plant unit 4 in Irsching reached an efficiency of 60.75% in trial operation and thus became the new world record holder.

- In January 2016, the Lausward power plant in Düsseldorf , using an SGT5-8000H gas turbine from Siemens, achieved a maximum net efficiency of 61.5% during test drives before it was officially commissioned. With maximum heat extraction, more than 85% fuel efficiency is achieved and carbon dioxide emissions of only approx. 230 g / kWh.

- On April 28, 2016, the Électricité de France power plant in Bouchain , which uses the 9HA gas turbine from General Electric , was included in the Guinness Book of Records as the most efficiently operating combined cycle power plant with a combined efficiency of 61.4% .

- On March 27, 2018, the power plant in Nagoya , operated with the 7HA gas turbine from General Electric , was included in the Guinness Book of Records as the most efficiently operating combined cycle power plant with an efficiency of 63.08% .

- On June 5, 2018, Siemens announced in a press release an overall efficiency of 63% for a power plant commissioned in Great Britain using a class SGT-9000HL gas turbine.

- Outlook: In 2018 General Electric offered an 826 MW gas turbine, which should achieve an efficiency of over 64% in the combined cycle; A combination efficiency of 65% is targeted for the early 2020s.

By using a back pressure turbine or a turbine tap , the thermal energy of the steam can still be used for district heating . Due to the higher back pressure, however, the mechanical work generated and the exergetic efficiency of the overall process are reduced. If you look at the lower part of the power plant cycle in the Ts diagram (condensation) as a Carnot process (see steam power plant, section Ts diagram) with a back pressure instead of 0.037 bar (= 30 ° C condensation temperature), then at 1 bar back pressure ( = Generation of district heating at 100 ° C) the Carnot efficiency related to the efficiency achieved by 17%. Thus, instead of 58%, an efficiency for generating mechanical work of 48% is achieved. After steam extraction at 1 bar, 52% of the fuel energy used is available at a temperature level of 100 ° C. This enthalpy of the steam consists of the enthalpy of condensation or evaporation at 1 bar / 100 ° C; it amounts to

and the remaining sensible heat in the no longer usable condensate from

.

Without heat utilization, at a condensation temperature of 30 ° C, the enthalpy is dissipated from the cooling tower to the environment. In the case of full heat utilization, this is reduced to 292 kJ / kg. Then, in addition to converting 48% of the fuel energy into mechanical work, 45% of the input energy is available as thermal energy at 100 ° C. It should be noted that the energy in the heating water consists of only 19% exergy and the remaining 81% anergy . Therefore the different degrees of efficiency must not be added together. However, the sum of the two degrees of efficiency cannot exceed 100%.

The total emissions are therefore very low compared to the energy generated. In addition to the high efficiency, further advantages of a combined cycle power plant are the short construction time and the short start-up time of the gas generator, which is why this type of power plant can be used to compensate for load peaks . However, a CCGT power plant requires comparatively expensive fuels, which is why more recent research is concerned with CCGT coal-fired power plants.

The construction of combined cycle power plants is tax- privileged in Germany if the efficiency of the plant is over 57.5%. The state waives its due natural gas tax of € 5.50 per megawatt hour if this efficiency is exceeded and the total availability of the power plant is more than 70%. There are similar discounts in other countries as well.

costs

Combined cycle power plants can be built comparatively quickly and inexpensively. The construction time and the investment costs are only about half of a coal-fired power plant of the same output. In the base load range with 8,000 operating hours per year, however, coal-fired power plants can compensate for the higher construction costs because of the lower fuel costs. The more flexible combined cycle power plants are therefore primarily used in the peak and medium load range with 4,000 operating hours per year.

Combined cycle power plants

Operation of the gas turbine with coal dust is initially not possible, as ash is produced during the combustion of coal , which would quickly destroy the blades of the gas turbine through abrasion . Separating the ash from the hot gas stream is difficult on an industrial scale and is part of current research. However, there is the possibility of initially converting hard coal into coke oven gas at least partially in a coking plant and using it in a combined cycle power plant. The remaining solid coke can be converted into electricity in a conventional steam power plant .

Another form is the coal- fired combined cycle power plant , which presents itself as a coal-fired steam power plant in combination with a gas turbine. The gas turbine is operated with natural gas and drives a generator . The exhaust gases have a high when leaving the gas turbine temperature and a high content of oxygen , making them even as supply air for a fired coal boiler can be used, in turn, the water vapor provides for a steam turbine with coupled generator. This process is used, for example, by the Gersteinwerk near Werne an der Lippe , which works with an overall efficiency of 42%.

Another variant on an industrial scale are coal-fired power plants that gasify coal in a lack of oxygen . The resulting heat - almost a third of the total energy - is converted into electricity in a normal steam power plant, while the carbon monoxide produced is burned in a gas turbine after the ash has been removed - i.e. converted into CO 2 . The overall efficiency is also higher than that of simple steam power plants.

Combined cycle nuclear power plants

High-temperature reactors generate such high coolant outlet temperatures that the use of gas and steam combined cycle power plants would be conceivable, but gas turbines have been studied intensively for decades, but could not be made ready for use in a nuclear environment.

Individual evidence

- ↑ World's Most Efficient Combined-Cycle Power Plant | GE Power. Retrieved June 17, 2018 .

- ↑ Patrick R. O'Donoughue et al .: Life Cycle Greenhouse Gas Emissions of Electricity Generated from Conventionally Produced Natural Gas. Systematic Review and Harmonization . In: Journal of Industrial Ecology . tape 18 , no. 1 , 2014, p. 125-144 , doi : 10.1111 / jiec.12084 .

- ↑ J. Antoñanzas et al. Towards the hybridization of gas-fired power plants: A case study of Algeria . In: Renewable and Sustainable Energy Reviews 51, (2015), 116–124, doi: 10.1016 / j.rser.2015.06.019 .

- ↑ Register information from the German Patent and Trademark Office: (Register number 1134324)

- ↑ Mitsubishi Heavy Industries J-Type gas turbine, s. Mitsubishi press release ( Memento of the original dated August 7, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ The most powerful power plant in the world. In: Image of Science. May 20, 2011, accessed September 9, 2019 .

- ↑ Düsseldorf: Kraftwerk breaks numerous world records ( Memento of the original from January 28, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. . In: newspaper for local economy , January 28, 2016. Retrieved January 28, 2016.

- ↑ Most efficient combined cycle power plant .

- ↑ GE-Powered Plant Awarded World Record Efficiency by Guinness . Power engineering. March 27, 2018.

- ↑ Siemens builds one of the world's most efficient combined cycle power plants in Great Britain . Siemens. 5th June 2018.

- ↑ HA technology now available at industry-first 64 percent efficiency . GE Power. 4th December 2017.