Combined heat and power

Combined heat and power ( CHP ) or combined heat and power ( WKK ) is the simultaneous generation of mechanical energy and usable heat , which arise in a common thermodynamic process. The mechanical energy is usually converted directly into electrical current. The heat is used for heating purposes, as local or district heating or for production processes as process heat , e.g. B. in the chemical industry, then it is an industrial power plant . In most cases, heat is provided to heat public and private buildings, then it is a thermal power station .

It is therefore in the power generation coupled useful heat from fuels and ensure that the supply of unused waste heat reduces to the environment. Combined heat and power enables fuel savings of up to a third of the primary energy compared to the separate generation of electricity and heat, but at the same time the electrical efficiency of the power plant is somewhat reduced. Smaller CHP systems with an electrical output of around 100 kW are of great importance for the supply of commercial enterprises, indoor swimming pools and residential areas or individual apartment buildings, so-called combined heat and power units (CHP). Although smaller systems are offered on the market, they only have a very small share in electricity and heat generation compared to photovoltaic systems .

The advantage of CHP is the lower fuel requirement for the simultaneous supply of electricity and heat, which greatly reduces pollutant emissions. Funding from the Combined Heat and Power Act (KWKG) and the Renewable Energy Sources Act (EEG) is intended to accelerate expansion. Since CHP plants fired with fossil fuels continue to emit carbon dioxide , comprehensive climate protection can only be guaranteed in the long term if they are fed with renewable energies , such as B. Biomass and synthetic natural gas from renewable surplus electricity.

introduction

The spectrum of electrical and thermal output from CHP systems ranges from a few kilowatts to several hundred megawatts. For a long time, so-called mini and micro combined heat and power plants, the size of a washing machine, have been on the market for use in single-family houses, residential buildings, small businesses and hotels. This means that CHP solutions are now available for the entire spectrum of heat requirements.

Thermal power plants , which cover a large part of the electricity demand in Germany, usually only generate electricity with the heat released from a fuel. If the waste heat z. B. used for process heat or fed into a heating network, these are called CHP systems; they have a higher degree of utilization . While purely electricity-generating plants achieve efficiencies between 33% (older plants) and 61.5% ( gas and steam combined cycle power plants ), CHP plants achieve efficiency levels of up to 85% and higher.

Compared to the currently best technologies for the separate generation of electricity and heat, CHP systems achieve primary energy savings of up to 30%, depending on the supply situation . The fact that the savings are not even higher on average is due to the fact that the real electricity and heat demand is subject to strong fluctuations. Especially when households only have a low heat requirement in summer, this means that some heating power plants run in condensing mode and cannot produce any CHP electricity. This is remedied by installing district heating storage tanks to temporarily store the CHP heat until it is called up by the heating customers.

The high potential for savings that has not yet been realized in Germany has prompted the legislature to promote CHP in order to overcome market barriers that exist due to the central supply structures in the electricity industry that have grown over 100 years.

technology

In the case of combined heat and power, part of the steam produced is extracted in a power plant for heating purposes. As a result, the efficiency of the generation of electrical energy decreases somewhat; However, the total degree of utilization can increase to around 90% if the waste heat is fully utilized.

Fuels

The principle of CHP can be used with any fuel and any heat source with a temperature level from approx. 200 ° C. In addition to fossil energies such as hard coal , lignite , natural gas and heating oil , renewable energies such as biogas , sewage gas , vegetable oil , wood , pellets , bioethanol , solar thermal and geothermal energy as well as municipal waste ( waste incineration and landfill gas ) as well as nuclear energy can be considered .

Operation with synthetic hydrogen or methane from the power-to-gas process is also possible, with which surpluses from renewable energies can be stored in the long term. Since this type of heat generation is very loss-intensive and therefore requires significantly more energy overall than, for example, alternative heat generation with heat pump heating , heat-controlled CHP systems are viewed as largely unsuitable technology for a future renewable energy system with sector coupling . On the other hand, electricity-controlled CHP systems are considered to be important techniques for keeping the energy requirements low for reconversion in such a system.

Design and mode of operation

A distinction is made between the power and heat-controlled design of CHP systems, depending on the reference variable or the priority assigned to one of the two forms of energy. Current-controlled systems optimize the electricity yield, heat-controlled systems optimize the heat yield. The highest degree of utilization is achieved with a heat-controlled design, because this results in the lowest energy losses. From an economic point of view, however, electricity-based driving is often more attractive, as significantly higher yields are achieved per kWh of electricity than per kilowatt hour of heat. Often an electricity-optimized, heat-capped operation is preferred in order to optimize the yield on the electricity side without having to dissipate the heat unused via an emergency cooler. In this case, the operation is geared to the electrical energy demand, whereby the CHP plant is shut down if there is no heat consumption or if the heat storage is full. The heat storage can be accomplished by using a district heating storage .

The useful heat generated is used via heating networks as warm water or water vapor via insulated pipes for heating buildings , for industrial purposes ( process heat ).

With high proportions of fluctuating renewable energies in the electricity system, heat-controlled CHP systems make the system integration of wind and solar power more difficult , as they generate electrical energy to cover the heat demand even if there is already a surplus of wind or solar energy. Such systems are called "must-run" power plants. In terms of the energy transition, electricity-controlled operation is therefore much more effective. To increase flexibility in operation and improve price elasticity , various additional components such as peak load boilers, heat storage , power-to-heat systems such as B. Electrode boilers or large central heat pumps can be installed. These can then take over the heat supply during times when only thermal but no electrical energy is required, so that the CHP plant can be shut down. The electric boilers and heat pumps can also use any excess electricity to generate heat.

By using large heat stores, the simultaneous production of heat and electricity in the CHP process can be temporally decoupled again, since thermal energy can be temporarily stored more cheaply than electrical energy. In this way, a CHP system can be operated with electricity and still guarantee the heat supply. In times of high electricity and low heat demand, the system can run at full load and load the excess heat into the storage tank. In times of low demand for electricity and yet high heat demand, the CHP system can be operated at partial load or completely switched off; the remaining heat can then be temporarily provided by the heat storage system. This balancing function of a heat storage in a CHP system on the electricity sector is also referred to as functional electricity storage .

Plant variants

So-called combined heat and power units (BHKW) are an increasingly popular variant . These are small to medium-sized CHP systems based on internal combustion engines or gas turbines in modular design. While with these systems the heat supply is limited to a certain object or to the immediate vicinity (e.g. a residential "block"), the larger thermal power stations are used for extensive district heating or to generate process heat in industry. In large-scale systems for district heating, the network losses are higher than in building-integrated combined heat and power plants, which reduces the efficiency of energy use. On the other hand, increases with increasing power of the systems power to heat ratio (ie the ratio of electricity to heat) and thus the Exergieausbeute , which in turn increases the efficiency.

CHP systems can include:

- Extraction steam turbines - or back pressure turbines ,

- Gas and steam turbines (CCGT) ,

- Gas turbines - with waste heat boiler ,

- Internal combustion engines or

- Fuel cell systems

A distinction is made between CHP plants with a fixed and variable power indicator according to the rigid and steerable joint production . In systems with a fixed power index, the electrical and thermal output has a fixed ratio σ. These CHP systems, such as B. internal combustion engines, gas turbines and back pressure turbines can only be switched on or off or operated at partial load. Systems with a variable power index, such as B. extraction steam turbines are more flexible in operation, since the P / Q 'ratio can be influenced in a wide range, which has advantages when the demand for electrical and thermal energy changes. In addition to partial load operation, the emphasis can be placed on the production of electrical or thermal energy.

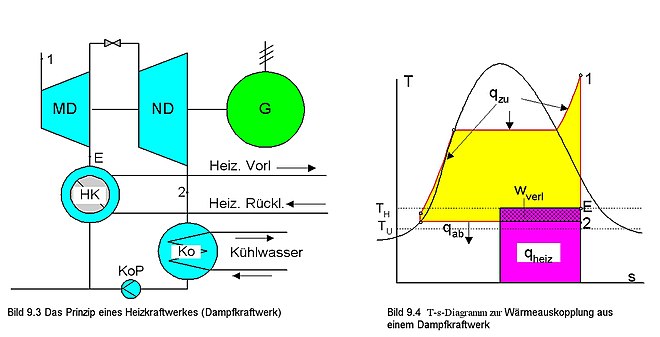

In the heating and power stations of the public supply that are operated with water as a working material - these are usually extraction steam turbines - the release of useful heat is accompanied by a reduction in electricity production (lower electrical efficiency ). The steam must be extracted before the last turbine stages so that its temperature is high enough for heating, which then generates less work in the low-pressure section. The ratio of electrical lower yield and recovered useful heat is referred to as the power loss indicator . The picture on the right shows the principle of removal in a simplified manner in the left part. The steam branched off after the medium-pressure section (MD) of the turbine , i.e. before the low-pressure section (LP), flows into the heating condenser (HK), where it is liquefied by releasing heat to the district heating circuit (temperature level around 100 ° C). From there the condensate is fed into the feed water circuit. The remaining steam works in the low-pressure part and is then liquefied in the condenser (Ko) at approx. 30 ° C (depending on the ambient condition) and fed to the feed water tank (not shown here) via the condensate pump (KoP) . The right side of the picture shows the associated idealized Ts diagram (see Clausius-Rankine process ) for an operating state in which half of the steam is used for heating purposes. The entire red area corresponds to the heat used, the upper hatched part of this area to the power loss in the low-pressure stage.

Of trigeneration (CHPC) is when the system can additionally provide refrigeration. The useful heat of the process is used to drive an absorption chiller . Despite the significantly higher investment compared to a compression refrigeration machine , the CHP system can be operated economically because the use of heat for air conditioning in summer increases the utilization of the CHP process.

Support measures

Funding in Germany

In Germany, CHP is generally promoted by the Combined Heat and Power Act (KWKG). Systems that use renewable energies in CHP (e.g. biogas CHP with heating networks) can optionally also be remunerated in accordance with the Renewable Energy Sources Act (EEG).

CHP law

With the law for the maintenance, modernization and expansion of combined heat and power ( Kraft-Wärme-Kopplungsgesetz (KWKG)) in the Federal Republic of Germany, the preservation, modernization and expansion of CHP systems that use gaseous or liquid fuels and are not funded by the Renewable Energy Sources Act. A further reduction in carbon dioxide emissions and the energy efficiency targets are to be achieved through increased use of CHP systems .

The CHP Act came into force on April 1, 2002. On January 1, 2009, an amendment to the CHP Act significantly expanded funding. Further amendments took place on July 19, 2012 and January 1, 2016. The goals of the KWKG have shifted over time: from an absolute saving in greenhouse gases to a relative share in electricity generation in Germany to an absolute value of the CHP net electricity generation. This was due, among other things, to the easier measurability.

The operators of very small CHP systems with an electrical output of up to 50 kW receive a fixed CHP surcharge as a market premium for 60,000 hours of full use; for larger CHP systems the funding period is 30,000 Vbh. The CHP surcharge on the fed-in electricity depends on the size of the system and is between 3.1 and 8.0 ct / kWh. Own consumption or CHP electricity used in area networks has not received any support since the 2016 revision, with the exception of small CHP systems up to 100 kW. In the plant segment from 1 MW to 50 MW, a tender for 200 MW per year has been introduced to determine the amount of the award. While all tenders have been slightly to heavily oversubscribed since the introduction of the tendering model in 2017, the bid and award amount in the tendering round in December 2019 was significantly below the tendered amount for the first time.

Since the combination of CHP systems and heat storage systems leads to a high degree of flexibility and at the same time efficient fuel use, the legislature has also included the promotion of heat and cold storage systems (see combined heat, power and cooling ) in the KWKG. Furthermore, the new construction and expansion of heating and cooling networks is funded with 30% of the applicable investment costs (or with small pipe widths of up to 100 mm with 100 euros per running meter).

Critics object that the subsidy is too low and that the conditions to be met are too high to help CHP achieve a breakthrough. Others complain that the regulations are too complex in interaction with other provisions of energy law, so that many interested parties are deterred.

Renewable Energy Sources Act (EEG)

With the amendment to the Renewable Energy Sources Act ( § 27 Paragraph 4 EEG 2009), which has been in effect since 2009 , the use of waste heat from electricity generation from biomass (e.g. in biogas plants and biomass thermal power stations ) was given a CHP bonus of 3 cents / kWh CHP electricity (EEG 2004: 2 cents / kWh) stimulated. This bonus was offset against the basic remuneration under the EEG and was payable by the operator of the upstream power grid. The bonus capable amount of current ( cogeneration power ) was calculated as the product of useful heat (in fact, used waste heat) and the current characteristic of the plant (electric power / Nutzwärmestrom, here is - different from above - with useful heat meant the theoretically usable portion; by the plant engineering such generator and heat exchanger , the power rating of a system is specified.). A high degree of electrical efficiency and the intensive use of waste heat thus increased the proportion of electricity eligible for bonuses. Various conditions had to be met in order to receive the CHP bonus (Annex 3 of the EEG 2009).

In addition, a further so-called technology bonus (innovation bonus ) of up to 2 cents / kWh was given when using certain CHP technologies ( fuel cells , gas turbines, steam engines, organic Rankine systems, multi-fuel mixture systems, in particular Kalina cycle systems, or Stirling engines ) (Appendix 1 of the EEG 2009). These surcharges and bonuses were indirectly passed on to all end consumers.

The 2012 EEG amendment abolished both the CHP bonus and the technology bonus. The CHP bonus is now integrated into the EEG basic remuneration and adopted as a minimum requirement for biomass plants, in that a heat utilization of at least 25 or 60 percent is prescribed if no more than 60 percent by mass of liquid manure fractions are used. Instead of the technology bonus, the EEG now provided for a gas processing bonus if lower methane emissions and lower electricity consumption could be demonstrated. With the last EEG reform in August 2014, the gas processing bonus was canceled without replacement to limit the costs of the EEG surcharge.

Tax breaks

For the fuels natural gas , heating oil and liquid gas , the energy tax , formerly " mineral oil tax ", was fully reimbursed until April 1, 2012 when used in CHP systems with an annual efficiency of at least 70 percent . Due to an application by the German authorities to the EU Commission that was too short-term, the processing of applications for energy tax relief was temporarily suspended in 2012. Due to a change in the law, the full relief will only be provided retrospectively from April 1, 2012 if the system has not yet been fully written off under tax law in addition to the minimum degree of utilization of 70 percent and is highly efficient in the sense of Directive 2004/8 / EC of the European Parliament.

In addition, no electricity tax (2.05 cents / kWh) has to be paid for electrical energy from systems of up to 2 MW electrical output that is used in the “spatial context” . This exemption does not only apply to CHP systems, but to any system with a maximum size of 2 MW.

Promotion in Austria

In Austria, there is a subsidy for fossil thermal power plants in the form that the energy taxes for the primary energy do not have to be paid if the electrical efficiency is over 30%. This means that heat generation in CHP systems is de facto tax-exempt or subsidized.

Fossil cogeneration was supported in Austria from 2004 to 2010 with a total volume of around 500 million euros in the form of market price surcharges on top of the electricity price (support tariffs); however, this form of funding has expired. In 2014 a law was enacted which provides for the promotion of electricity production from fossil fuel systems via CHP points, the volume of which, however, is only 38 million euros per year. Furthermore, power plants such as the Simmering power plant received investment subsidies in accordance with Section 24 ff of the Green Electricity Act 2012 for the adaptation work.

Funding in Switzerland

In Switzerland, thermal power coupling in biomass, wastewater treatment and waste incineration plants is indirectly funded by the federal government.

literature

- Martin Altrock u. a .: New legal framework for combined heat and power and renewable energies. AGFW Projektgesellschaft mbH, Frankfurt am Main 2009, ISBN 3-89999-015-3 .

- Wolfgang Zander, Martin Riedel (eds.): Practical handbook energy procurement. Loose-leaf work, ISBN 978-3-410-22628-4 .

- Ulf Jacobshagen, Markus Kachel: The Combined Heat and Power Act (KWKG) 2012. 2013, ISBN 978-3-410-23468-5 .

Web links

- Federal Association of Combined Heat and Power V.

- COGEN Europe, European CHP Association

- CHP basics , BINE information service

- CHP principle , BHKW-Infozentrum GbR

- Introduction to the topic of CHP in combined heat and power plants, BHKW-Forum e. V.

- CHP - what is it? (PDF file; 386 kB), University of Duisburg Essen

- Calculation of energy cost savings when using a micro-CHP (PDF file; 344 kB), ITG Institute for Technical Building Equipment Dresden Research and Application GmbH

- Micro-CHP - Home Power - for whom is this technology suitable? RWE Efficiency GmbH - energiewelt.de

- Swiss professional association for thermal power coupling

- Information platform of the German transmission system operators

Individual evidence

- ↑ Gunter Schaumann, Karl W. Schmitz (Eds.)., Combined heat and power. 4th edition Berlin Heidelberg 2010, p. 5f.

- ↑ Dominic A. Notter, Katerina Kouravelou, Theodoros Karachalios, Maria K. Daletou and Nara Tudela Haberlandad: Life cycle assessment of PEM FC applications: electric mobility and μ-CHP. In: Energy and Environmental Science 8, (2015), 1969–1985, doi : 10.1039 / C5EE01082A .

- ↑ a b c Combined Heat and Power Act - KWKG in the previous and current version

- ↑ a b c Renewable Energy Sources Act - EEG 2009 in all versions

- ↑ Volker Quaschning : Renewable energies and climate protection. 3rd edition Munich 2013, p. 102.

- ↑ Press release Siemens: Siemens achieves world records in Düsseldorf power plant "Fortuna" , accessed on March 21, 2016.

- ↑ Cf. Volker Quaschning : Sector coupling through the energy transition. Requirements for the expansion of renewable energies to achieve the Paris climate protection targets, taking into account sector coupling . Berlin University of Technology and Economics , June 20, 2016. Accessed April 8, 2017.

- ↑ See Michael Sterner , Ingo Stadler: Energy Storage - Demand, Technologies, Integration. Springer, Berlin 2014, pp. 709f.

- ↑ Martin Zapf: Electricity storage and power-to-gas in the German energy system. Framework conditions, needs and possible uses. Wiesbaden 2017, p. 129.

- ↑ Philipp Pfeifroth: Functional power storage , research center for energy industry

- ↑ Lagom.Energy: Publication of the current CHP and iKWK tender results by the BNetzA. February 9, 2020, accessed March 30, 2020 .

- ↑ Power plant in the basement - electricity companies hinder energy saving ( page no longer available , search in web archives ), manuscript for Frontal21 from April 15, 2008

- ↑ Modernization of CHP systems - secure long-term economic advantage

- ↑ Deletion of Section 27 Paragraph 4 No. 1 and 3 EEG

- ↑ Insertion of § 27c EEG

- ↑ The EU advises on energy tax relief for CHPs. Retrieved October 22, 2012 .

- ↑ Only partial energy tax relief for CHP units. November 13, 2012, accessed December 4, 2012 .

- ↑ CHP plants will receive the energy tax refund again in the future. November 13, 2012, accessed December 4, 2012 .

- ↑ Bundestag: Electricity Tax Act. In: Laws on the Internet. Federal Ministry of Justice and Consumer Protection, August 27, 2017, accessed on February 26, 2018 .

- ↑ https://www.ris.bka.gv.at/GeltendeFnahm.wxe?Abfrage=Bundesnormen&Gesetzesnummer=20002168&FetzungVom=2006-11-29 Consolidated Green Electricity Act 2006

- ↑ Investment funding for CHP plants

- ↑ Thermal power coupling (WKK). Section Promotion of WKK with renewable energies . Federal Office for Energy SFOE, accessed on April 11, 2012 .