Underground gasification

As underground gasification (UTG) is defined as the exploitation of coal deposits by underground gasification.

Coal seams often reach depths of several 1000 m. The coal-bearing layers of the Upper Carboniferous in Central Europe slope northwards to below the North Sea and reach a depth of up to 8,000 m. Since the limit for conventional hard coal mining is only around 1,600 m due to the geothermal gradient , more than 90% of German coal deposits cannot be extracted using conventional mining. In addition, the extraction in civil engineering is compared to the large-scale coal extraction in opencast mines such. B. in Australia much more expensive. Such deposits can only be exploited through underground gasification.

The use of air or air-steam mixtures leads to the production of fuel gas (mostly lean gas ); synthesis gases are produced when using oxygen-steam mixtures as gasification agents .

history

As early as 1868 Carl Wilhelm Siemens and in 1888 the Russian scientist DI Mendelejew considered underground coal gasification. The American engineer Anson G. Betts received three patents on underground gasification in 1910. In 1912, in his speech at the International Smoke Abatement Exhibition , William Ramsay suggested that coal should not be burned but gassed. This drew international attention to the idea. This led Lenin to respond to Ramsay in a 1913 Pravda article.

Ramsay was also the first to begin exploring underground gasification in Durham, UK. Because of his death in 1916, the experiments were not carried out. The next attempts were only carried out again in 1933/34 by Kirichenko in the Soviet Union in the Krutowa mine in the Moscow Basin , in Lisichansk in Donbass and in Shakhty . However, the calorific value of the gas produced was very poor. In 1934 there was an experiment in Leninsk , Kuzbass , with a significantly better calorific value. From 1935 a pilot plant was operated in Gorlowka , Donbass.

By the late 1950s, the Soviet UTG program was ready for use on an industrial scale. In 1964, however, research on underground gasification was scaled back due to newly discovered large natural gas deposits.

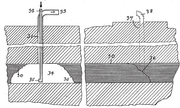

It was not until the energy crisis of 1973 that the technology was researched in the West with public funds. In the first American UTG program 1946–1959 in Gorgas (Alabama) , the electrolinking process , that is, connecting two bores using high voltage that burns a narrow channel, was invented. The second phase from 1973–1989 brought major breakthroughs for underground gasification. As in the USSR, however, the development of near-surface deposits was limited. In Centralia (Washington) , the CRIP process (in 1983 English controlled retracting injection point ) developed a teilverrohrte in which the injection well directional drilling leads to a defined point of injection.

| Test location | Coal type | Depth [m] | Operating time | gasified amount of coal [t] | generated gas volume [million m 3 ] |

|---|---|---|---|---|---|

| USSR | |||||

| Podmoskovna | Brown coal | 30-80 | 1947-1962 | 4,700 | |

| Angrenskaya | Brown coal | 120-200 | 1962-1977 | 5,000,000 | 400-1,400 |

| Yuzhno-Abinskaya | Hard coal | 50-300 | 1055-1977 (-1982) | 1,600,000 | 6,700 |

| United States | |||||

| Hanna | Brown coal | 85 | 1973–1979 (388 days) | 17,300 | 63.56 |

| Hoe Creek | Brown coal | 50-120 | 1976-1979 (123 days) | 5,100 | 12.18 |

| Pricetown | Hard coal | 270 | 1979 (12 days) | 234 | 1.39 |

| Rawlins | Brown coal | 30th | 1979-1981 (101 days) | 9,900 | 17.35 |

| Centralia | Brown coal | 75 | 1983 (30 days) | 13,315 | 1.78 |

| Hanna (Rocky Mountain I) | Brown coal | 110 | 1987-1988 (80 days) | 10,000 | 13.1 |

| Europe | |||||

| Thulin / Belgium | Semi-anthracite | 860 | 1986-1987 (200 days) | 340 | 0.55 |

tries

In Europe:

- 1981 in Bruay-en-Artois , France

- 1983–1984 in La Haute Deule , France

- 1982–198? in Thulin in Hainaut, Belgium

- 1992–1999 in El Tremedal , Spain

Commercial projects

The first commercial plant has been running in Angren (Uzbekistan) since 1961 . In the USA, coal bed methane has been mined in the Black Warrior Basin (Alabama) and the Powder River Basin since the 1980s .

Worldwide:

- Chinchilla (Queensland) , Australia

- Kingaroy , Australia

- Majuba , South Africa

Coal Bed Methanes

| component | unscratched coal (CBM) | active mine (CSM) | disused mine (CMM) |

|---|---|---|---|

| Methane (CH 4 ) | 90-95% by volume | 25-60% by volume | 30-95% by volume |

| Carbon dioxide (CO 2 ) | 2 - 4% by volume | 1-6% by volume | 1-15% by volume |

| Carbon monoxide (CO) | 0 vol% | 0.1-0.4% by volume | 0 vol% |

| Oxygen (O 2 ) | 0 vol% | 7-17 vol% | 0 vol% |

| Nitrogen (N 2 ) | 1-8% | 4-40% | 5 - 32% |

Coal Bed Methane (CBM) is the coal-bed gas released through a borehole in the unscratched rock. In contrast to this, the seam gas that occurs in mines is referred to as mine gas . In principle, a distinction is made between different forms of coal gases . Coal seam gases are naturally occurring coal gases. These include the seam gas and the mine gas. Furthermore, there are the gases that are produced by the actual mine work of coal mining: on the one hand, the coal seam methane (CSM), which is released by active mining; on the other hand, the Coal Mine Methane (CMM), which can still leak years after a mine has been closed.

While mine gases were feared in earlier times because of their explosiveness, they began to be used as fuel for energy in Germany as early as the beginning of the 20th century. The countries with the world's largest deposits of coal seam gas are China, Russia, the USA and Canada.

Web links

- Deutsche MontanTechnologie: Flözgas ( Memento from September 6, 2011 in the Internet Archive ), accessed on February 12, 2013

- Federal Institute for Geosciences and Natural Resources: Flözgas , accessed on February 12, 2013

- coal gas on clarke energy , accessed December 18, 2014

- Underground coal gasification as an energy source of the future? Retrieved December 18, 2014 from scinexx.de

- Utilization of Unmined Coal - Centennial of the Invention (2010)

Individual evidence

- ↑ Dieter Osteroth: From coal to biomass . 1st edition. Springer, 1989, ISBN 978-3-540-50712-3 , pp. 119-124 .

- ^ A b c Heinrich Wilhelm Gudenau, Helmut Knappstein, Klaus Guntermann, Florian Fuhrmann, Rainer Zechner: Research activities on the underground gasification of hard coal at great depths . In: The natural sciences . tape 76 , no. 6 , June 1989, pp. 237-242 , doi : 10.1007 / bf00368632 ( PDF ).

-

↑ Patent US947608 : Method of utilizing buried coal. Registered December 27, 1906 , published January 25, 1910 , inventor: Anson G. Betts. , Patent UK21674 .

- ^ A b c d Alexander Y. Klimenko: Early Ideas in Underground Coal Gasification and Their Evolution . In: Energies . tape 2 , no. 2 , June 2009, p. 456-476 , doi : 10.3390 / en20200456 ( PDF ).

- ↑ Where in the world?

- ↑ Coalbed Methane in the Powder River Basin, Wyoming and Montana: An Assessment of the Tertiary-Upper Cretaceous Coalbed Methane Total Petroleum System

- ↑ Ergo Exergy: εUCG Technology p. 4

- ↑ Classification of coal seam gases , accessed on February 12, 2013.