LPG

| LPG | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| other names |

LPG (Liquefied Petroleum / Propane Gas), GPL (gaz de pétrole liquéfié) |

||||||||

| Brief description | Knock-proof petrol made from liquefied gases at a pressure of 5–10 bar | ||||||||

| origin |

Oil and gas refineries |

||||||||

| Characteristic components |

LPG propane , LPG butane ; Ratio 95: 5 to 30:70, usually offered as a "summer mix" 40:60 and as a "winter mix" 60:40 |

||||||||

| properties | |||||||||

| Physical state | gaseous under standard conditions (liquid under pressure) | ||||||||

| density |

0.54-0.60 kg / L (under pressure) |

||||||||

| calorific value |

46 MJ / kg, 12.8 kWh / kg; 24.8 MJ / L, 6.9 kWh / L |

||||||||

| Octane number |

105–115 RON (depending on the mixture) |

||||||||

| Boiling range |

Propane: −42 ° C, butane: −0.5 ° C |

||||||||

| Carbon dioxide emissions from combustion |

0.236 kg (CO 2 ) / kWh = 1.64 kg (CO 2 ) / L = 3.04 kg (CO 2 ) / kg |

||||||||

| safety instructions | |||||||||

|

|||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||||

Autogas ( LPG for short in international parlance , from the English Liquefied Petroleum Gas or GPL , from the French G az de p étrole l iquéfié ) refers to liquid gas intended for use in vehicle internal combustion engines , a variable mixture that mainly consists of butane and propane .

Are not designated as LPG compressed natural gas for natural gas vehicles (CNG from English compressed natural gas ) as well as down-cooled liquefied natural gas (LNG from English Liquefied Natural Gas ) which also fuels for internal combustion engines.

Name and origin

The main components of autogas, propane and butane, are liquid at room temperature under comparatively low pressure (less than 10 bar) and can therefore be transported very economically. Therefore one speaks of liquid gas. They evaporate under normal pressure and can be used as a gaseous fuel.

These gases are produced as “wet drilling gas” in natural gas and oil production and as a by-product in the refining of oil (e.g. for the production of gasoline or diesel ). Originally, their economic value was so small that they were flared on the spot . But now they are liquefied under pressure, used in various areas as an energy source and as a raw material in the chemical industry.

In Regulation (EC) No. 1099/2008, the European Union defines LPG as “light paraffin-based hydrocarbons, which are produced as secondary products in refining processes and in the stabilization of crude oil and the processing of natural gas; these are primarily propane and / or butane. Propylene , butene , isobutene, and isobutylene can also occur. For transport and storage, LPG is generally liquefied under pressure. "

LPG as fuel

Liquid gas ( butane / propane ) is used as a fuel for gasoline engines . The first German gas filling station went into operation in Hanover in 1935. It was already widespread in Italy and the Netherlands in the 1970s .

It burns more environmentally friendly than gasoline . Even taking into account the volume-related additional consumption, the pollutant emissions of nitrogen oxides are reduced by about 80% and that of unburned hydrocarbons by about 50%. According to a study from 2012 by the Saarland University of Applied Sciences (HTW), CO 2 emissions are reduced by an average of 16.4%. The start-up phase with gasoline and the transport of the liquefied gas are also included in this calculation.

LPG exhaust gases can be better converted into vehicle catalytic converters at low temperatures . Combustion engines powered by natural gas and liquefied gas in forklifts may be operated in closed rooms. Gasoline and diesel forklifts emit soot , unburned hydrocarbons and, above all, nitrogen oxides .

In direct comparison with gasoline, depending on the gas system (see below), there is a volumetric additional consumption of 5 to 20% for LPG, due to the lower density and the lower energy content per liter of liquid volume compared to gasoline. Petrol has a density of approx. 0.76 g / cm³, liquid gas, depending on the mixing ratio, between 0.58 and 0.60 g / cm³ under pressure. The lower density of LPG is partly compensated by the higher calorific value of approx. 46 MJ / kg (12.8 kWh / kg) against 42 MJ / kg (12 kWh / kg). With newer systems with direct injection nozzles, depending on the installed system, no starting gasoline or gasoline is required during operation.

At first, LPG was very common in private taxis (e.g. all taxis in Istanbul and Bangkok ), as well as in state taxis and driving school vehicles in the late 1970s and 1980s in the GDR, and later in the private motor vehicle sector in the 1980s Years in Austria due to low prices. Because of the higher taxation for private vehicles, it became uninteresting again in Austria. However, Wiener Linien switched all buses to LPG, since LPG remained tax-free for public vehicles.

Today, liquefied petroleum gas is an established fuel in most European countries. After a long period of growth, the number of autogas cars and LPG filling stations has stagnated in recent years and is currently even declining slightly. This is particularly related to the general uncertainty about a possible tax increase on LPG.

Until the end of 2018, liquid gas (LPG / autogas) will be taxed as a fuel in Germany at 18 cents / kg (= 9.74 cents / l). At the beginning of June 2017, the Bundestag voted to extend the funding of LPG beyond 2018, but to a decreasing extent. Accordingly, the tax will increase by 2.47 cents / l per year from 2019 to 40.9 cents / kg (= 22.1 cents / l) in 2023 (all tax rates plus VAT). According to this, a liter of LPG including VAT will cost 14.7 cents more from 2023. In Switzerland LPG is tax deductible in 2008. This made it around 0.25 francs per liter cheaper.

Vehicle conversion

End of the individual acceptances

Since October 1, 2017, the individual acceptance of a retrofit (assessment according to § 21 StVZO) is no longer permitted. The operation of a vehicle with a new LPG system is only permitted if the system manufacturer has approval for the vehicle concerned in accordance with the ECE R115 standard. Before buying a gas system or before buying a vehicle that may need to be converted, it is essential to check whether there is a gas system for which the necessary documents for the respective vehicle are available. Exceptions are vehicles in emission class Euro 2 and older, as well as import vehicles (TSN zeroed) or individually approved vehicles.

System installation

In almost any vehicle with a gasoline engine , a liquid gas system can be installed. Installation in a car is relatively straightforward. Usually costs of around 1800 to 3500 euros arise , depending on the number of cylinders, performance and the emissions standard to be achieved. The empty weight of an LPG system is around 40 kg.

Gas tank

There are various installation options for the tank:

- In the spare wheel well (34 to 94 liters), the missing spare wheel should then be replaced with a puncture spray or run- flat tire .

- In the trunk (60 to 200 liters), mostly in cylinder shape.

- Underfloor tanks: They are mainly used on passenger cars where the spare wheel is under the vehicle.

- on the roof: especially on buses

LPG tanks must remain about 20% unfilled in order to have a buffer volume when the tank temperature rises. The buffer volume and the pressure resistance of the tanks are designed so that they can withstand temperatures of 60 to 70 ° C, depending on the size of the tank. So z. B. a 60-liter tank can only be filled with a maximum of 48 liters. This is achieved with automatic filling volume limiters ("filling stop"). Another safety measure is a pressure relief valve, which allows gas or liquid gas to escape into the environment in the event of excess pressure.

Ranges

The liter consumption in gas operation is higher and the kilogram consumption lower than in gasoline operation. During the conversion, the petrol supply system is completely retained, so that it is possible to switch between petrol and liquid gas operation ( bivalent drive ) and the other is still available after one tank has been emptied. This means that LPG cars can also achieve a total range of over 1000 km.

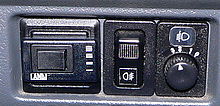

Toggle switch

With a cold start , the engine initially runs in gasoline mode and automatically switches to gas mode after a few minutes when the small cooling water circuit has reached a temperature of around 35–40 ° C. This is necessary so that the liquid gas does not freeze during expansion and evaporation in the pressure reducer. When the engine is warm, you can switch between petrol and LPG mode manually at any time while driving. When the gas tank is empty, the control automatically switches back to petrol operation and issues a warning.

Additive

For vehicles with an unfavorable material pairing between the alloys of the valve and valve seat, in addition to the unconditional compliance with the medium speed range when driving on LPG, the addition of an additive is recommended. The electronically controlled systems are complex as the additive dose is calculated and injected based on the engine load. The “1 ‰ example” applies in principle. If 100 liters of gas is consumed over a distance of 1000 km, the optimal amount of additive added is 100 ml. The additive consumption is therefore linear in relation to the gas consumed. This means that in vehicles with higher consumption of LPG, the additive consumption is correspondingly greater.

Shortly before the container filled with additive is empty, the dosing pump automatically shuts down and sends a signal to the control unit. This then initiates the switch to petrol operation. This prevents running in LPG operation without additives. In addition to the signal from the LED , which is placed in the dashboard, a buzzer warns the driver that the additive container will soon be empty. This leaves enough time to refill the additive.

Electronically controlled systems only add additives when the driver uses LPG. The additive is therefore only consumed when running on LPG.

Some retrofitters also recommend installing additives in the intake tract or adding an additive to the petrol and gas tank in order to reduce wear on the valves and valve seats when the fuel type and combustion conditions change, as the combustion times are longer than those with the same fuel-air mixture of gasoline. This means that the exhaust valves are subjected to significantly more thermal loads. In some vehicles, the valve seats are significantly less temperature-resistant than in other vehicles (so-called soft valve seats), so that under certain circumstances engine damage can occur in gas operation. Longer combustion times and the resulting engine damage can be avoided from the outset if a built-in gas system in the upper load range is set to be "richer" (lambda value <1). Every now and then, savings should be made on the consumption of LPG, and the mixture is set too "lean". This often leads to engine damage or, in the long term, to premature valve wear. As an alternative to installing an additive, there are gas systems that add small amounts of gasoline when operating on gas. The amount of fuel required for the respective vehicle can be adjusted. Some LPG systems also switch completely to petrol operation at high speed and back to LPG as soon as the speed is lower again.

disadvantage

- In addition to the main inspection and after every work on the gas system, a gas system test (GAP) is required for a fee, although not every test center has the necessary test device. A GAP that is carried out independently of the HU and certified in writing is recognized if it was not more than 12 months ago.

- Retrofitting carried out by third parties can lead to the loss of warranty claims.

- A valve protection additive is necessary for older engines if the valve seats are not hardened at the factory.

- Increasing the curb weight and possibly reducing the loading space reduces the maximum payload of the vehicle.

- A spare wheel cannot be carried with a wheel tank.

- If the display elements (and / or the on-board computer) of the vehicle are not designed for additional gas operation when retrofitting, misleading error messages and false alarms can occur.

- The crash behavior can change by stiffening the body.

Liquid gas vehicle technology

Cars operated with LPG are either started with gasoline and then, depending on the installed system, switched to gas operation by switch or automatically in order to avoid any warm-up problems, or they start directly with LPG. A distinction is made between Venturi systems, sequential systems and LPI systems.

The first two types of system have in common that the pressurized liquid gas in the tank is fed to the engine in gaseous form via an evaporator and pressure regulator. Since the gas cools down considerably when it evaporates, similar to a cold spray, the evaporator is heated with cooling water. For this reason, most LPG systems only switch to gas from a cooling water temperature of around 30 ° C in order to prevent the evaporator from icing up at low outside temperatures.

In a two-year project, employees of the Saarland University of Applied Sciences (HTW) in Saarbrücken succeeded in converting a small car to a monovalent gas drive. The vehicle no longer needs petrol to start and only emits 90.9 grams of carbon dioxide per kilometer. The monovalence is achieved, among other things, by a liquid injection of the LPG into the intake pipe with an increased pressure of up to 15 bar. The LPG only becomes gaseous after the injection due to the expansion. In most previous LPG systems, however, an evaporator is used that first has to be brought to operating temperature by the cooling water.

LPI systems have been offered since 1995. These systems use a fuel pump to convey liquid gas under pressure in a ring line, from where it is injected into the intake tract in liquid form through metering valves. The heat absorbed for evaporation has a cooling effect on the intake air; depending on the gas throughput, the intake temperature is reduced by 5 to a maximum of 15 Kelvin . This leads to a slight increase in performance (see turbo engine / charge air cooler ) or a lower loss of performance in relation to evaporator systems. Combustion requires fuel and the oxygen contained in the air. Cold air contains more oxygen per volume than warm air. In a classic gasoline engine, the fuel is injected as an aerosol , which requires almost no volume. Gaseous fuels displace air and thus reduce the amount of oxygen in the cylinder. With LPG, 3% of the air is theoretically displaced, with natural gas up to 10%.

The LPG combustion takes place with lower pollutant emissions and increased smoothness. These effects include a. due to the high knock resistance of 105 to 115 octane and the homogeneous mixture formation. In contrast to aerosols, gases can be mixed very quickly and very evenly with the combustion air. By avoiding local air deficiencies or excesses, the formation of undesirable combustion by-products such as carbon monoxide, partially / unburned hydrocarbons or nitrogen oxides is suppressed.

Gas-air mixing methods

Venturi technique

Venturi technology is the oldest and cheapest solution. A Venturi nozzle is installed in front of the throttle valve in the intake duct, which automatically mixes gas into the intake air, which is requested from a vacuum-controlled evaporator. The working principle is similar to a carburetor. This technology basically works without any regulation, only the evaporator is set to a certain fuel-air mixture. Current regulated Venturi systems still have a control device that u. a. evaluates the existing lambda probe and optimizes the mixture by fine-tuning the amount of gas. Due to the principle-related narrowing of the intake cross-section, a slight loss of performance and increased consumption can be expected in Venturi systems. Many air flow meters work according to the same principle even in older vehicles (Quelle, Bosch K-Jetronik, air flow meter). The experience of the retrofitter is particularly important here. In addition, this technology can cause backburning in the intake tract. This phenomenon, known as backfire, is not a coincidence, however; it only occurs with faulty technology, e.g. B. by too lean or too rich a mixture (analogous to carburettor slapping), by defective or worn ignition systems or also by leaking inlet valves. Pressure relief valves built into the intake manifold and / or into the air filter box, which open in the event of an explosion and allow the pressure to escape, can prevent damage from Backfire. The (regulated) Venturi technology is suitable up to the Euro 2 emissions standard (or in some cases also D3) without losing a tax class.

Semi-sequential systems

Semi-sequential systems use an electronically controlled metering valve, which injects the gas into the intake ports of the cylinders using a star-shaped gas distributor. A cross-section narrowing in the intake tract and thus a loss of performance does not take place. The risk of backfire is also lower, as the gas is supplied directly in front of the inlet valves and therefore there is no significant ignitable mixture in the intake tract. These systems often have their own programmable map generator for gas operation, which only picks up the signal from the lambda probe, the speed (e.g. camshaft sensor) and the throttle valve position from the vehicle. Therefore, older vehicles up to the Euro 3 emissions standard can also be equipped with this system. However, the partially sequential systems are now offered very rarely. Compared to a Venturi, these are considerably more expensive to purchase and more complex to set due to the map to be programmed. Therefore, the price often exceeds the residual value of the vehicle to be converted.

Fully sequential systems

Fully sequential systems (state of the art in 2009) have their own metering valve for each cylinder. These modern systems often no longer have their own autonomous map computer, but instead convert the fuel injection duration determined by the petrol control unit into an equivalent injection duration for gas. Instead of the petrol nozzle, a gas nozzle is actuated; the gas control unit only determines pressure- and thus load-dependent correction factors. Therefore, the conversion and, above all, programming is easier, but requires an existing sequential or group-sequential fuel injection. Modern vehicles have had this technology since the mid-1990s. The introduction of the Euro 3 and Euro 4 pollutant standards with EOBD (Euro On-Board Diagnosis ) then made sequential fuel injection imperative. The Euro 4 emissions standard is easily achieved or undercut (manufacturer information). In any case, an exhaust gas confirmation of the currently valid (or the vehicle corresponding) emissions standard is to be requested, otherwise an acceptance (TÜV) in Germany is not (or very difficult, i.e. expensive) to obtain. A certificate of correct installation and the leak test in accordance with VDTÜV 750 etc. must also be requested. (This is also necessary for the aforementioned systems and is often not available for systems installed abroad.)

LPI systems

LPI is the abbreviation for L iquid P ropane I njection and translates liquid propane injection, ie LPG injection. The sequential gas injection in liquid form is probably the latest (so-called) 5th generation of LPG systems. This technology was introduced in the early 1990s. These systems are usually a bit more expensive compared to evaporation systems. The liquid gas pumps and tanks are relatively noisy and were vulnerable in the first series versions. There are now special liquid gas pumps which have been homologated according to the applicable ECE 67R-01 directive and are designed for operation with LPG. Since the pump is also a separate component of an LPG system, it must be marked with a corresponding test number according to 67R-01. Only then can the approval of the pump for LPG be clearly recognized.

Manufacturers advertise combustion chamber cooling because the LPG is injected into the engine in liquid form. Even if the LPG is injected into the intake manifold well before the intake valves of the combustion chambers and the LPG is already evaporating in the intake manifold, the charge air flow of the engine is still cooled by the heat required for the evaporation and thus the degree of delivery is increased. This does not apply to systems with evaporators. Here the necessary heat of evaporation is taken from the cooling water and can no longer be used to increase the degree of delivery.

The Dutch manufacturer Vialle has registered the name LPI under trademark protection. The manufacturer ICOM therefore calls the technology of liquid gas injection JTG.

With the Vialle system, a separate map is generated using a separate control device - various fields should already be specified.

The ICOM system uses LPG injection nozzles, the characteristics of which are similar to gasoline injection nozzles. This allows the injection times of the fuel control unit to be used. The gas control unit only works as a switch between gasoline and gas injection nozzle. Only the gas injection nozzles have to be calibrated during installation. Complicated setting of the gas control device is not necessary as with the evaporator systems. Further advantages are the non-existent maintenance costs for filter changes or readjustments of the software for driving.

Refueling

Refueling a vehicle with LPG must be done under pressure so that the fuel remains liquid. There are several connection systems ( ACME, DISH, bayonet , Euronozzle ) to create a pressure-tight connection ; Suitable LPG tank adapters are usually kept in the vehicle, but can also be borrowed at many petrol stations.

The handle of the nozzle is locked in the open position after the connection has been made. Not only is the line opened (as with other fuels), but a pressure-tight connection is first established. The refueling process only begins when a dead man's button on the fuel pump is pressed and held (occasionally a foot switch is offered for this function). This should ensure continuous supervision of the refueling process. By law, LPG tanks may only be filled up to 80% of their nominal tank volume in order to ensure adequate protection against bursting in the event of overheating. There is a float valve in the tank which mechanically closes the filler neck when the maximum permissible fill level is reached, whereupon the filling system stops refueling because the permissible refueling pressure is exceeded.

At 30 ° C, propane develops a vapor pressure (and thus internal tank pressure) of around 11 bar, in Germany most fuel pumps deliver a refueling pressure between 12 and 14 bar. Since the gaseous component in the tank is compressed and thus heated during refueling, which means that the internal tank pressure rises significantly above the idle value, it is not always possible to achieve the maximum filling volume at summer ambient temperatures.

distribution

Germany

In July 2014, Germany had the previous record number of 6,852 LPG filling stations. In view of the price and supply situation, saturation appears to be set in, the number has since declined slightly and stood at 6,469 filling stations in June 2018.

Europe

There are extensive gas filling station networks in many European countries:

| Netherlands | approx. 2,100 |

| Belgium | approx. 650 |

| Italy | 3.164 |

| Poland | approx. 5,000 |

| Czech Republic | about 700 |

| Slovakia | about 100 |

| Romania | approx. 1,300 |

| France | approx. 1,700 |

| Great Britain | approx. 1,400 |

| Hungary | about 500 |

| Turkey | about 10,000 |

In Belgium, the Czech Republic, Ireland, the Netherlands, Poland and Turkey, the density of LPG filling stations per inhabitant is higher than in Germany.

In several other European countries, only basic services for tourists and travelers are guaranteed:

- Austria: 32 public filling stations (as of May 2013). As a fuel, liquid gas is not promoted in Austria beyond an exemption from the mineral oil tax, because renewable fuels are preferred.

- Switzerland: 52 well-known petrol stations (as of May 2013)

- Slovenia: 35 well-known petrol stations (mostly motorway petrol stations) (as of May 2013)

- Portugal: 95 known petrol stations (as of May 2013)

- Spain: hundreds of petrol stations spread across the country

- Sweden: 52 known petrol stations

- Norway: 115 known gas stations

In Denmark and Finland, LPG is almost not available at all.

Worldwide

South Korea (22%), followed by Japan (9%), Turkey (8%), Mexico (8%) and Australia (7%) has the largest share of all countries using LPG. LPG is also widespread in Croatia (129 filling stations), Russia, Armenia, China, Thailand, Cambodia, Vietnam, the USA and Canada. In Ukraine, almost every filling station also offers LPG, as almost 50% of all cars are equipped with LPG systems.

Prices and costs

The prices for autogas in Germany with uniform taxation by the energy tax vary greatly from region to region.

When comparing prices with petrol, it must be taken into account that the liter consumption is up to 25% higher, since liquid gas has a lower calorific value per liter (but a 10% higher calorific value per kilogram).

Unmixed liquid gas (LPG) as fuel is taxed in Germany with a mineral oil tax of only 9.74 ct / l (= 18 ct / kg, = 1.41 ct / kWh). Diesel or gas oil (sulfur content ≤ 10 mg / dm³) is taxed at 4.7 ct / kWh, petrol (sulfur content ≤ 10 mg / dm³) is taxed at 7.3 ct / kWh. (All taxes plus VAT )

The conversion costs and the fuel consumption are essential factors for the amortization . A correct conversion of a car can cost around 2,500 euros.

The running costs are increased by regular leakage tests (usually carried out during the general inspection) and regular maintenance work on the gas system (filter change). In systems with liquid gas injection, there are no maintenance costs for filter changes and readjustment of the software because the signals continue to come from the original control unit.

Investment amortization

The period in which the conversion to LPG pays for itself depends on the expenses and costs for the conversion, the changed maintenance and repair costs, consumption, the annual mileage and fuel prices. Only the low fuel prices have a positive effect - they have to outweigh the other factors. The breakeven point is usually only reached after a certain distance. This amortization distance is shorter, the greater the original fuel requirement was with gasoline, the higher the (kWh-related) price difference to gasoline and the lower the investment and maintenance costs. In cases of low fuel consumption, the distance to be traveled increases. Since usually only the cheaper fuel prices are included positively in the amortization calculation, an increase in fuel prices can completely prevent amortization.

Amortization calculators make the calculation easier, but usually do not take into account any loan interest. The amortization period is completed when the amortization distance has been covered.

Comparison of liquid gas (LPG) and natural gas (CNG) for motor vehicles

| Abbr. | designation | composition | Energy density (in MJ / l) |

Density (in kg / m³) |

Pressure (in bar) |

Temperature in the pressure tank |

|---|---|---|---|---|---|---|

| LPG | Liquefied Petroleum Gas / Low Pressure Gas | Propane, butane | 25th | 540 | 2 to 8 | Ambient temperature |

| CNG | Compressed natural gas | methane | 9 | 130 | 200 to 250 | Ambient temperature |

| LNG | Liquefied Natural Gas | methane | 21st | 400 to 500 | 8th | −170 to −120 ° C |

| CGH2 | Compressed hydrogen gas | hydrogen | 28 to 40 | 250 to 700 | Ambient temperature | |

| CCH2 | Cryo-compressed hydrogen | hydrogen | 80 | 4th | −220 ° C |

Chemically

- LPG is mainly a propane - butane mixture, the octane number , depending on the butane content, is between 105 and 115, i. d. Usually from 103 to 111 octane RON with mixed gas in the ratio propane to butane 60:40 or from 104 to 107 octane RON at 40:60.

- CNG mainly consists of methane (around 84–99% by volume), the octane number is 120–140.

Physically

- LPG is stored in liquid form at a pressure of around 5–15 bar (around 400 g of fuel per liter of gross tank volume).

- CNG is stored in gaseous form at around 200 bar (approx. 130 g fuel per liter of pressurized gas tank volume) and reduced to 7 bar by a high pressure regulator.

Engine power

Every gaseous fuel (LPG and CNG) has a displacing effect, therefore the possible air supply in the intake tract is reduced. This means that less oxygen is available for combustion than with fuels added in liquid form. This means that less maximum power can be available. In the part-load range that is relevant for everyday use, however, the engine output can even increase slightly through a more homogeneous and better mixture. In the case of charged engines with a turbocharger or compressor, the loss of power can be compensated for by a higher boost pressure and thus a higher oxygen charge. The high octane number of well over 100 of LPG and CNG favors this fact. In the case of classic naturally aspirated engines, however, a performance loss depending on the fuel must be expected with both fuels.

- LPG: One molecule of propane consumes five oxygen molecules during combustion, one molecule of butane six and a half. Depending on the gas composition, up to 4% of the cylinder filling consists of LPG. Old Venturi systems or their nozzles (only permitted up to Euro 2) can cause a performance loss of up to 10% due to additional throttle losses in the intake tract, which, however, is only noticeable when the maximum performance is requested. With newer sequential evaporator systems, a power loss of up to 3.8% can theoretically be expected, but this is not noticeable in practice. A liquid-injecting system cools the air down during evaporation using the necessary heat of evaporation in the intake tract, which improves the cylinder filling (analogous to classic gasoline injection in front of the inlet valve). Therefore, there is often no measurable loss of performance or even a slight gain in performance can be observed. This is further increased by the higher octane number , which allows the ignition point to be shifted in the "advance" direction. This is set by the knock sensor .

- CNG: One molecule of methane (methane is the main component of natural gas) consumes two oxygen molecules during combustion, so significantly more natural gas (typically 12%) has to be metered into the cylinder, as a result of which even more atmospheric oxygen is displaced. As a result, this oxygen is not available for combustion and a power loss of 12 to 15% (depending on the increased load) must be expected. The loss of performance can be very noticeable, especially in vehicles with a weak engine and high full-load fueling.

Carbon dioxide emissions

- The LPG CO 2 emissions are 1640 g per kilogram. LPG reduces CO 2 emissions by around 15% compared to gasoline combustion. Calculation method for propane: density of the liquid fuel approx. 500 g / l, molar mass propane 44 g / mol, each combustion produces 3 CO 2 at 44 g / mol each. That gives 500/44 * 3 * 44 = 1500 g / l. Plus 30% more consumption (see above) corresponds to one liter of premium gasoline with an energetically identical amount of propane gas, replacing CO 2 emissions of around 2.0 kg per liter. For premium gasoline, 2.32 kg / l is calculated (see [Fuel consumption]). If butane is used, the higher density and the higher carbon content generate more CO 2 per liter, but the additional consumption is reduced by the higher calorific value. Data that are exact to the decimal point cannot be given due to the temperature-dependent density of the liquefied gas and the seasonal change in the propane / butane ratio.

- CNG reduces CO 2 emissions by around 25% compared to gasoline combustion. In engines that are optimized for CNG combustion, a greater reduction in CO 2 is theoretically possible by increasing the compression and the resulting increase in efficiency. However, this assumes that the engine has been designed for the higher compression in gas operation. On the other hand, in reserve operation, even with 100-octane gasoline, consumption is higher - more than if a super-plus-optimized vehicle had to run on regular gasoline.

Tank technology

LPG can be retrofitted in wheel recess tanks without loss of luggage space. Cylinder tanks are available with volumes of over 200 liters; Wheel recess tanks are offered up to over 60–95 liters, depending on the recess size. The installation of additional tanks is z. B. possible with pickups or vans. The net tank volume is 80% of the gross volume. This is prescribed for safety reasons (expansion in the hot vehicle) and is ensured by a shut-off valve in the vehicle. The test pressure of these tank systems (TÜV) is 40 bar. The usual operating pressure below 10 bar. Since LPG tanks are not high-pressure containers, a large number of tank shapes are possible. However, cylinder and ring tanks are widespread.

distribution

- LPG: is currently offered nationwide at 6200 filling stations in Germany (as of February 2020). Approx. 75% of the LPG filling stations also carry petrol and around 45% are open 24 hours a day. The density of LPG filling stations is lowest in Brandenburg.

- CNG: is currently offered at just over 900 filling stations in Germany (as of mid-2013). Approx. 81% of CNG filling stations also carry petrol and around 65% are open 24 hours a day. With the exception of North Rhine-Westphalia, the density of CNG filling stations is low.

- General: Since June 2006, there has been the legal basis for nationwide uniform advance signage on motorways for LPG and CNG filling stations. If there is a low density of gas filling stations, it is advisable to inquire about the gas filling stations on the route before starting your journey. Pure gas filling stations are often not manned by staff, so that payment is only possible by card (EC card or customer card). Unoccupied petrol stations are usually a little cheaper than regular petrol stations.

distribution

- Like gasoline and diesel fuels, LPG is usually transported to the petrol station by road and thus pollutes road traffic. However, the filling station operator is not necessarily tied to a regional gas supplier.

- CNG, on the other hand, consists of natural gas and finds its way to the consumer via pipes. Petrol stations get their natural gas from the network of local gas supply companies; the compression to the tank pressure of more than 220 bar takes place on site. Rural CNG filling stations without a connection to a natural gas network are difficult or expensive to supply. Here make biomethane fueling stations is a sensible alternative.

Practical consequences

- LPG can be used with relatively simple retrofitting, the achievable range with 40 liter tanks is 450 to 500 km and thus higher than with CNG. If a gasoline engine is retrofitted to run on gas, LPG is often an option for reasons of cost and space.

- Due to the higher pressure, CNG requires thicker-walled and therefore heavier tanks and, when retrofitted, allows ranges of 240 to 300 km, less than with LPG, depending on consumption. If a vehicle is equipped with underfloor tanks ex works, then even with CNG ranges of over 650 km can be achieved with one tank of fuel. Often new purchases and retrofitting are funded by the local gas supply company, the average funding amount is around € 500.

safety

properties

LPG and CNG are extremely flammable mixtures. LPG also contains some of the carcinogenic 1,3-butadiene . According to Annex VI of the European Chemicals Ordinance, the GHS labeling of mixtures such as LPG, which contain a concentration of less than 0.1% 1,3-butadiene, does not need to be classified as carcinogenic.

Safety regulations

Liquefied gas installations are classified installations for the industrial safety regulations , they must therefore repeatedly through a before commissioning and in certain periods approved body be examined ( gas system testing ). The provisions of the Industrial Safety Ordinance regarding explosion protection must also be observed.

Legal restrictions on parking autogas vehicles in underground garages have been relaxed since 1998. In the garage regulations of most federal states, it is generally allowed to drive with LPG cars in underground garages . Restrictions apply in Berlin , Bremen and the Saarland . However, sometimes the garage owners prohibit entry by means of signs. Pay attention to the house rules of the garage owner. The ordinances are not uniform within Austria either, as they fall within the competence of the federal states .

A LPG tank consists of a steel wall approximately 3.5 mm thick and is designed for an operating pressure of a maximum of 20 bar. The TÜV safety test prescribes a test pressure of 40 bar.

In the event of extreme damage, safety valves also ensure that the gas filling is blown off in a controlled manner or when exposed to heat - for example in the event of a vehicle fire - that the gas filling is burned off in a controlled manner, thus preventing the risk of explosions. However, compliance with the test intervals and guidelines is important for the safe use of the new technology.

Security technology

Regarding the safety risks, the ADAC writes : “There is no evidence from practice that there is an increased safety risk with these vehicles, not even from those countries where a relatively large number of autogas vehicles are registered. Crash and fire tests show that LPG cars are no more dangerous than comparable petrol vehicles. ”LPG tanks and their pipe connections are equipped with different safety systems: The filling line connection is equipped with a non- return valve that prevents gas from escaping if the pipe breaks. The transport line into the engine compartment is secured with a solenoid valve when the tank is removed, which closes immediately if the power supply is interrupted. If the pressure loss is too high, the gas control unit interrupts the power supply to the solenoid valve. If the vehicle power supply no longer works in the event of an accident, the described solenoid valve is definitely closed due to the lack of power supply.

In the event of a fire, most tanks are tested up to an overpressure of (30… 35) bar (burst pressure approx. 60… 90 bar). Depending on the type of tank (1-hole / 4-hole), either a separate pressure relief valve or a pressure relief valve integrated into the multi-valve is installed. This opens at a pressure of approx. (25 ... 28) bar, which ensures that the gas is released in a controlled manner in the event of a fire and the tank cannot burst. A redundant safety valve can also be installed for increased safety. This consists of a total of 2 pressure relief valves, e.g. B. one in the primary multi-valve and another in the secondary multi-valve, or 2 pressure relief valves in the main multi-valve.

Movable containers

With the spread of refueling options, gas containers are increasingly coming into circulation, as shown in the picture: Older gas container in the form of a gas cylinder . They are the same size as the 11 kg gas bottles used in motorhomes , balloons and for grilling at parties and celebrations, but are technically identical to the tanks built into vehicles. For motorhome drivers in particular, they promise a considerable increase in flexibility, since the usual bottles can often not be refilled abroad, but refueling is increasingly possible in more places.

Despite the technical conformity of the containers with gas tanks, refueling at a gas filling station in Germany is not permitted. According to Section 2, Paragraph 12, No. 3 of the Ordinance on Industrial Safety and Health, these were bound to the TRG ( Technical Rules for Compressed Gases ), specifically to TRG 440. There, Section 4.1 requires that only tanks according to TRG 380 may be filled, in TRG 380 It then says, among other things, in § 2.1: "LPG tanks are permanently connected to motor vehicles or other portable operating systems and are to be filled volumetrically ..." This makes it clear that only permanently installed containers, such as in the picture: Gas pressure containers permanently installed in a motorhome for to see external refueling , may be filled. The background is that if you hold movable containers at an angle, they can become overfilled.

In a campaign in 2010, flyers similar to the one shown in the reference were distributed to the petrol stations. The petrol station operators were sensitized again and since then there have been frequent rejections of petrol customers with such containers.

However, the filling station operators sometimes send away customers whose vehicles with permanently installed fuel bottles meet the requirements. The reason is often that the gas is not used to operate an internal combustion engine. However, there is no technical or tax justification for this. The use as fuel is the use to which the highest energy tax rate is linked, namely the full taxation according to § 2 Paragraph 1 No. 8 and Paragraph 2 No. 2 EnergieStG . If the energy product is only burned, as in a motorhome, a reduced tax rate according to Section 2 (3) No. 5 EnergieStG could be applied.

literature

- The Autogas Journal, Germany's magazine for alternative fuels No. 1 , Dr. Martin Steffan Media, first edition February 2008, ISSN 1865-8644

- Sven Geitmann: Alternative Fuels - What is the best way to drive? Hydrogeit Verlag, Nov. 2010, ISBN 978-3-937863-15-3

- Ralf Ortmayr, Wolfgang Schüler: Advice on autogas information and tips self-published, 1st edition July 2006, ISBN 978-3-00-017181-9

- Technical rules for liquid gas: TRF 1996; Publisher: DVGW / DVFG; 1st edition 1996, ISBN 3-87793-039-5

Web links

Individual evidence

- ↑ Erich Rummich: Energy storage: Basics, components, systems and applications . expert-Verlag, Renningen 2009, ISBN 978-3-8169-2736-5 , p. 62 ( limited preview in Google Book search).

- ↑ a b Registration dossier on petroleum gases, liquefied ( GHS section ) at the European Chemicals Agency (ECHA), accessed on March 25, 2019.

- ↑ Entry on Petroleum gases, liquefied in the Classification and Labeling Inventory of the European Chemicals Agency (ECHA), accessed on March 25, 2019. Manufacturers or distributors can expand the harmonized classification and labeling .

- ↑ Regulation (EC) No. 1099/2008

- ^ Olaf Grohmann, History of the water and energy supply of the city of Hanover: From the beginnings to the present , Hanover 1991, p. 217.

- ↑ Richard van Basshuysen (Ed.): Otto engine with direct injection - process systems development potential , 3rd edition, Springer Vieweg, Wiesbaden, 2013, ISBN 978-3-658-01408-7 , p. 191

- ↑ LPG tax after 2018 , as of June 2017.

- ↑ a b c ADAC: The ADAC cost comparison - convert to LPG? , accessed March 5, 2017.

- ↑ a b c d GTÜ Gesellschaft für Technische Zusammenarbeit mbH: Things worth knowing about the topic of gas vehicles, October 13, 2014 , accessed on March 5, 2017.

- ↑ a b c autogas-umruestungen.de: autogas-umruestungen.de - advantages of LPG conversion , accessed on March 5, 2017.

- ↑ GAPplus.de , accessed on June 9, 2017.

- ↑ Valve protection for LPG operation. Retrieved June 10, 2017 .

- ↑ Project CO2-100minus of the Saarland University for Technology and Science (HTW)

- ↑ a b de.statista.com , accessed June 8, 2017.

- ↑ LPG stations in Romania - myLPG.eu. In: www.mylpg.eu. Retrieved December 17, 2016 .

- ↑ LPG stations in Hungary - myLPG.eu. In: www.mylpg.eu. Retrieved December 17, 2016 .

- ↑ a b c d e f g h LPG & CNG gas station directory , gas-tankstellen.de, accessed May 5, 2014.

- ↑ Federal Ministry for Agriculture, Forestry, Environment and Water Management: Inquiry response no. 3697 / J, regarding the promotion of liquid gas as fuel (PDF; 27 kB) from January 26, 2006.

- ↑ MyLPG.eu , accessed January 8, 2018.

- ↑ MyLPG.eu , accessed January 8, 2018.

- ↑ MyLPG.eu lists four stations nationwide for Denmark, not a single one for Finland.

- ↑ Global Autogas Industry Network: Statistics ( Memento of October 7, 2007 in the Internet Archive ).

- ↑ Example of an amortization calculation. Retrieved June 10, 2017 .

- ↑ Autogas-Online ( Memento of the original from January 4, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ CO2 emissions from a car

- ↑ ECHA: Annex VI CLP ( Memento of the original dated August 7, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Basic knowledge about LPG: technology and the environment. ADAC, archived from the original on April 24, 2008 ; Retrieved on September 26, 2010 : “A rear crash and fire test carried out by ADAC in 2008 with an Opel Astra station wagon converted to LPG showed that the gas tank housed in the spare wheel well was not damaged in the event of an impact and that all lines and connectors were sealed by activating electromagnetic shut-off valves. Even in the subsequent fire test, the safety concept with programmed draining valves worked perfectly, there was no risk of explosion at any time. "

- ↑ LPG: ADAC Crashtest - LPG , accessed on March 5, 2017.

- ↑ TRG 440 , PDF, read: March 2, 2011.

- ↑ TRG 380 , read: March 2, 2011.

- ↑ State Office for the Environment, Water Management and Trade Inspectorate Rhineland-Palatinate (ed.): Ban on refueling portable pressurized gas containers (refuelable gas bottles): Notes for gas station operators ( Memento of the original from June 7, 2015 in the Internet Archive ) Info: The archive link was inserted automatically and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF), accessed on March 2, 2011.