Gasoline engine

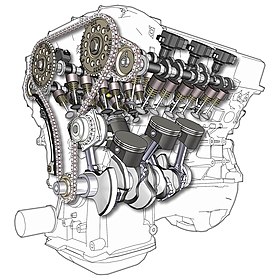

The FE engine is a design from the 1950s and has the traditional features of the gasoline engine. The carburettor, with which the gasoline-air mixture is formed, sits on top of the intake bridge in the middle. In this engine, the intake and exhaust valves are "suspended", i.e. from above, and are actuated by a central camshaft, which is installed in the middle between the cylinder banks, via tappets, bumpers and rocker arms.

The Otto engine is an internal combustion engine , i.e. a heat engine with internal combustion. The characteristic of the Otto engine is the compression of a mixture of fuel and air and the subsequent spark ignition by spark plugs . Gasoline engines with reciprocating pistons are available as two-stroke or four-stroke engines , with two-stroke engines one cycle of the crankshaft takes one turn, with four-stroke engines two. The four-stroke engine is the more common type.

The torque delivered by the gasoline engine is traditionally adjusted by throttling the intake mixture with a throttle valve . The previously common assignment of " external mixture formation " with carburetor or intake manifold injection for gasoline engines and " internal mixture formation " for diesel engines (fuel and air are only mixed in the combustion chamber ) has no longer been clear in every case since the introduction of gasoline direct injection in gasoline engines.

The name "Otto engine" goes back to a suggestion by the VDI in 1936 and was first used in 1946 in DIN No. 1940. It is named after Nicolaus August Otto , to whom the invention of the four-stroke process was ascribed. The aviation piston engine shown by Otto at the Paris World Exhibition in 1867, however, is not a gasoline engine, but an atmospheric gas engine, the functional principle of which differs from that of the gasoline engine.

history

Aviation piston engine

In 1864 Nicolaus August Otto co-founded the world's first engine factory NA Otto & Cie. Together with Eugen Langen . in Cologne, from which the DEUTZ AG gas engine factory emerged in 1872, which engaged Gottlieb Daimler as technical director and Wilhelm Maybach as head of engine design. Until 1876 Otto developed a flying piston engine , also known as an atmospheric engine, following a two-stroke gas engine patented by Lenoir in 1860 . In this engine, the pressure of the burnt gas hurls the piston freely up the cylinder. On the way back, as soon as the gas pressure has dropped to atmospheric pressure, it does work via a rack and a freewheel. In the end position of the piston, the exhaust gas is expelled and a fresh gas-air mixture is let in.

At this time the four-stroke engine was invented, for which Christian Reithmann received several patents on October 26, 1860 and, independently of that, Alphonse Beau de Rochas in France in 1862. The main innovation was the compression cycle and the valve control required for it.

Otto also acquired a German patent for a four-stroke engine in 1877, the year the “ Imperial Patent Office ” was founded. This powered by coal gas four-stroke -Motor made 3 PS (about 2200 W) at 180 min -1 . It was produced from 1877 and sold as "Otto's new engine". The licensee Crossley Brothers in Manchester advertised it as an Otto engine . About 5000 copies were built by Deutz and its licensees.

Dugald Clerk invented a two-stroke engine in 1878 and received a patent for it in Germany on February 11, 1879.

Because of the older patent claims and the previous inventions of the four-stroke engine, the so-called Otto patent (patent 532 by Deutz ) was revoked by court on January 30, 1886 and 1889 in Germany. Gottlieb Daimler and Carl Benz were therefore able to build and sell four-stroke engines in 1886 without hesitation. Independently of this, Siegfried Marcus also built a motor vehicle with a gasoline engine in Vienna from 1888 to 1889 . The worldwide patents outside Germany remained with Crossley. The name was retained from this engine construction company in the form of a product line of marine engines from the engine manufacturer Rolls-Royce . The historic site in Openshaw ( Manchester ) was closed in 2010.

Technology (four-stroke petrol engine)

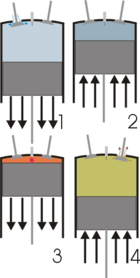

- 1st cycle: suction:

- The inlet valve (top left) is opened, the piston moves down and sucks the fuel-air mixture (or only air in the case of direct injection) into the cylinder, often supported by overpressure in the intake pipe, generated by a turbocharger or a compressor.

- 2nd cycle: Compress:

- The inlet and outlet valves are closed, the piston compresses the fuel-air mixture to approx. 20 bar. In engines with direct injection, the fuel is added. Just before top dead center, the spark from a spark plug ignites the fuel-air mixture.

- 3rd cycle: work:

- The fuel-air mixture burns at a maximum pressure of around 80 bar at top dead center. The flame front spreads at a speed between 5 and 60 m / s (i.e. much slower than the detonation speed of explosives or the speed of sound in air). The hot gas generates an average additional pressure of just over 10 bar. By pushing the piston down, the gas does work , it delivers power to the piston.

- First, combustion is a slow, laminar process. The flame front spreads concentrically at a speed of about 0.2 m / s. During this laminar phase, the combustion is incomplete and inefficient, producing the majority of the pollutants in the exhaust gas. With the transition into the turbulent combustion phase, which penetrates the combustion chamber with a flame front speed of over 200 m / s, the combustion becomes efficient and mechanically usable.

- The combustion generates a hot gas at high pressure (over 100 bar) in the relatively small combustion chamber, which drives the piston in a straight motion towards the crankshaft. This movement is converted into the rotating movement of the crankshaft via the connecting rod , also known as the connecting rod .

- 4th stroke: Ejection:

- The exhaust valve (top right) is opened, the piston pushes the combustion gases, which are still almost 1000 ° C hot, out of the cylinder.

Fuels

In addition to the usual motor gasoline , liquid gas (propane and butane), CNG natural gas (methane), biogas , sewage gas , landfill gas , mine gas as well as ethanol / methanol , hydrogen and theoretically all other combustible gases can also be used as fuels for gasoline engines . Engine settings such as ignition timing / ignition strength, geometric compression ratio and air / fuel ratio must be matched to the fuel. Mixed operation is possible at the same time or alternatively (to a limited extent), but then usually requires appropriate adjustments.

Mixture formation and ignition point

The fuel - usually engine gasoline - is atomized in the fresh air drawn in; either before the intake by means of a carburetor or by intake manifold injection , or since around the turn of the millennium after intake with gasoline direct injection . In car engines, injection has mostly been electronically controlled since the late 1980s.

Theoretically, the ignition takes place shortly after top dead center, but earlier due to the ignition delay (up to approx. 40 ° before TDC). In modern engines, the ignition point is precisely calculated by an electronic engine control depending on the load and speed. In the past, there were also adjustment mechanisms operated manually or using flyweights and vacuum units.

Two- and four-stroke

In the case of a two-stroke engine, at the end of the working stroke and at the beginning of the compression stroke, the exhaust of the combustion gases and the introduction of the fresh mixture take place simultaneously, often with the latter displacing the former. In small engines, for example in gardening tools or road vehicles, the piston usually controls the inlet and outlet times by opening or covering the gas ducts in the appropriate position. With carburetor engines or manifold injection, scavenging losses are unavoidable, which has a negative effect on consumption. With direct injection, the scavenging losses can be significantly reduced. Another method to reduce scavenging losses in a limited speed range is to use a resonance exhaust . The pressure wave with which the exhaust gas stream shoots into the exhaust when the exhaust ports are opened is reflected. The pressure wave rushing back pushes the fresh gas, which had already flowed into the exhaust at the end of the flushing process, back into the cylinder.

Furthermore, the usable piston stroke for compression and the work cycle is shorter than the total stroke between the two dead centers , since it only begins when the overflow and outlet channels are closed or ends when the channels open. For this reason, a lower power is achieved in the work cycle (at the same speed) than with the four-stroke process, which is partly compensated by the fact that the two-stroke engine has a work cycle every 360 ° crank angle instead of every 720 ° as with the four-stroke engine. With two-stroke engines, a better power-to-weight ratio is possible compared to four-stroke engines , but a disadvantage in terms of specific fuel consumption remains. In simple, small two-stroke engines, the intake air is pre-compressed in the crankcase, which is why there is no lubricating oil there: such two-stroke engines use an oil-gasoline mixture to lubricate the engine. Larger and more complex two-stroke engines can have a closed lubricating oil circuit, but then require a charge pump or blower to fill the cylinder .

In the four-stroke engine, on the other hand, the intake and exhaust strokes are separate and each cylinder only has a power stroke every two revolutions. To control the gas exchange, a valve control is necessary, which is usually implemented via camshafts that run at half the engine speed. That means more constructive effort, additional friction as well as higher weight and volume than the two-stroke engine - but this is mostly justified by the lower fuel consumption . Furthermore, four-stroke engines can be better tuned to a wider speed range thanks to the valve control . In two-stroke engines, the resonance oscillation of the gas column in the intake and exhaust tract is decisive for the degree of filling in the cylinder; a good cylinder filling and thus good performance and good torque is therefore only possible in the resonance range of the intake and exhaust system, i.e. in a relatively narrow speed range.

Two-stroke gasoline engines are used in applications that require a low mass-performance ratio and not fuel costs , such as in the leisure sector ( mopeds , mopeds , light aircraft , model aircraft or jet skis ), for portable work equipment ( chainsaws , generators , lawn mowers ) or special sports equipment ( Moto-Cross - and Trial motorbikes).

features

The classic features of the gasoline engine are:

- Spark ignition: The mixture is ignited at a certain point in time by the spark from a spark plug .

- External mixture formation: Fuel and air are already mixed before compression (exception gasoline direct injection, see below in this section).

- Quantitative control : The engine torque is set with the amount of fuel-air mixture supplied through the throttle valve or (in special cases since the turn of the millennium) with controlled intake valves.

- Combustion flame : The combustion flame is a premixed flame .

Source:

Otto engines with gasoline direct injection no longer fully correspond to these characteristics: The direct injection of the fuel into the combustion chamber is not tied to the inlet control times of the valves and can therefore only take place later in the compression phase. This enables stratified charges, i.e. zones in the cylinder with different mixture compositions, for example in the case of a lean- burn engine : a rich or stoichiometric fuel ratio (i.e. 14.7 parts air: 1 part fuel) is in the area of the spark plug and a lean mixture in the rest of the combustion chamber.

Even HCCI engines , which work self-igniting or externally igniting depending on the speed and load, do not correspond to the classic features of a gasoline engine, but are generally referred to as gasoline engines if they are designed to run on gasoline.

Displacement

The size of the displacement is an important characteristic for the classification of engines. The displacement describes the volume that is displaced by the piston between bottom and top dead center . In the case of multi-cylinder engines, the displacements of all cylinders are added.

For motor vehicles, cubic capacities from approx. 0.4 liters were / are common, the smallest engines for model airplanes in glow-igniter design have a cubic capacity of only 0.16 cm³. At 13.5 liters, the Pierce Arrow from 1912 marked an upper mark, while the BMW 803 aero engine developed in the 1940s had a total displacement of 84 liters.

Efficiency

The maximum efficiency is around 40% and is achieved today by engines that have a high mechanical compression in the so-called Atkinson cycle .

See also

- Otto cycle

- Wankel engine (rotary piston engine)

- Homogeneous compression ignition (HCCI), also Diesotto engine (CCS), a combination of diesel and gasoline engine

- Leanen

- Split engine (new 2 + 2 stroke principle for higher efficiency)

- Critical point (thermodynamics) injection of supercritical gasoline

- Engine repairs

Web links

- Franz Winter: mass balancing of reciprocating engines (animated) (animated GIF )

- Knospe - Ostwaldgymnasium Leipzig: Interactive FlashLet of a 4-stroke Otto engine (requires Adobe Flash )

Individual evidence

- ↑ a b c engine of progress. October 28, 2019, accessed December 23, 2019 .

- ^ Decisions in nullity proceedings against the patents of the Deutz'er Gasmotorenfabrik number 532, 14254, 2735 ; in: Patentblatt and excerpts from the patent specifications, January 30, 1886, accessed on April 6, 2014.

- ↑ Rolls-Royce Closes Engine Manufacturing in Openshaw, Manchester Evening News, accessed March 7, 2016 .

- ↑ Stefan Pischinger, Ulrich Seiffert (ed.): Vieweg Handbook Motor Vehicle Technology , 8th edition, Springer, Wiesbaden, 2016, ISBN 978-3-658-09528-4 , p. 348.

- ↑ [1] ; "Motor vehicle energetically considered" from FU Berlin, accessed on February 12, 2018.