Rotary engine

The Wankel engine is a rotary piston engine (RKM) that has been named after its inventor Felix Wankel . With a Wankel engine, the combustion energy is converted directly into a rotary movement without the detour of a lifting movement, as is the case with reciprocating piston engines (HKM). In principle, there are two kinematic versions: the rotary piston Wankel engine (DKM 54) and the rotary piston Wankel engine (KKM 57), where the number stands for the year of creation. Only the rotary piston Wankel engine designed by Hanns-Dieter Paschke (1920–2015), which is generally referred to as a Wankel engine, could gain economic importance.

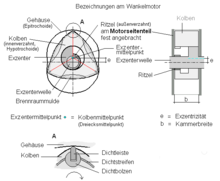

In the KKM 57P (designed in 1957 by Hanns Dieter Paschke), the curved-triangular rotary piston, known as the rotor, simultaneously performs the functions of power delivery and the control of gas exchange processes. The rotary piston rotary engine has an eccentric shaft and thus a low imbalance, which can be completely compensated by means of counterweights. The rotary piston Wankel engine DKM 54 has no eccentric shaft. Here the runner and the oval-arched envelope figure ( cycloid ) rotate unbalanced around their own centers of gravity. The axes are thus mounted eccentrically to one another. With the DKM 54, the external rotor is the force-emitting element, the internal rotor only serves as a shut-off part to control the gas exchange.

technology

Description of the workflow

The rotary piston engine works on the four-stroke principle . When the piston runs past the inlet slot, the volume of the working chamber increases and the amount of fuel -air mixture corresponding to the chamber volume is drawn in. As the working chamber becomes smaller and smaller as the rotary piston continues to rotate, the fuel-air mixture is compressed in the second working cycle. According to the gas law, it heats up in the process. When the fuel-air mixture has reached its highest density and has passed the spark plug , the mixture is ignited. The heat released during combustion leads to an increase in pressure , whereby usable work is performed on the rotary piston while it continues to rotate and the volume of the working space increases again: this is the working cycle.

After reaching the outlet slot, the exhaust gas is expelled. This cycle is run through by each of the three rotor flanks, which means that three ignitions take place with one rotor revolution. The combustion chamber is delimited by the rotor flank, the corresponding section of the chamber and the side walls.

The eccentric shaft of the rotary engine rotates by 1080 ° for one working cycle. This means that it takes three revolutions of the eccentric shaft until a flank of the rotor has passed through all four cycles. Because of the clocks running simultaneously on all three flanks, a working cycle that extends over 270 ° takes place with each revolution of the eccentric shaft. For comparison: a four-stroke reciprocating engine needs 720 ° for one work cycle , a single-cylinder engine only works during half of every second crankshaft revolution because two strokes are necessary for a gas exchange . If control times and work processes are related to the eccentric shaft, the Wankel engine achieves twice the volume flow of a four-stroke reciprocating engine with the same displacement at the same speed .

geometry

In a rotary piston engine, a triangular rotor rotates in a double-arched housing and constantly touches the housing wall. The contour of the rotary piston consists of three flattened circular arcs and looks like a bulbous triangle, similar to a Reuleaux triangle . It represents the inner envelope curve (math. An elliptical integral) to the housing, which has approximately the shape of an oval indented on the long side . The exact contour of the housing is an epitrochoid, which is generated as a so-called wheel curve . It arises as the course of a marked point on a smaller roller wheel when it rolls on a larger wheel without slipping. The shape of the wheel curve is created according to the radius ratio of the two wheels. In the case of the Wankel engine, the radii of the base circle are related to the rolling circle as 2: 1 and result in the familiar housing contour. For the real motor, the housing contour selected is an equidistant to the wheel curve at a distance from the tip radius of the sealing strip. The change in the angle of attack (tilt angle) of the sealing strip advantageously results in a constant migration of the contact line with the running layer back and forth over the sealing strip tip, so that the sealing strips can follow the housing contour with low wear. The equidistant also includes a sufficiently large clearance for the sealing strip and the runner within the trochoid. The rotor (rotor) together with the housing (stator) forms three independent, alternating large chambers. It takes along the eccentric of the eccentric shaft mounted in the center of the motor via the rotor bearing. The rotor center moves on a circular path with radius e ( eccentricity ); At the same time, e also corresponds to the distance between the eccentric center point and the eccentric shaft center point.

The toothing of piston and pinion results from the speed ratio of piston and eccentric shaft. The toothing has no force-transmitting function, but only supports the precise guidance of the piston. In the case of the Wankel engine, the tooth ratio of the internal toothing of the rotor to the external toothing of the pinion is 3: 2; For example, with 30 internal teeth of the rotor, this results in 20 external teeth for the pinion. This results in three revolutions of the eccentric shaft once the piston has rotated around its center point. The rotor bearings and the main bearings as well as both roller bearings as bearings to be carried out, which only on the type of lubrication depends (mixed or pressure lubrication).

The geometry of the Wankel engine represents a selection from a range of possibilities which result when either internal rotors or housings with varying roll curves are produced.

Engine structure

Designations, concepts, relationships

The chamber volume in a Wankel engine with a trochoid is:

and is calculated as:

with ... radius of the base circle ... eccentricity ... chamber width ... equidistant

The equidistant to the trochoid is not a trochoid, furthermore the sealing strips do not touch at and . Therefore, the formula for calculating the chamber volume is not exact, but it can be neglected.

For the four-stroke work process to run, the eccentric shaft of the roll motor must make three full revolutions (1080 °). Since a work cycle takes place at the same time on each piston side with a phase shift of 360 °, the entire work volume is sucked in once per eccentric shaft rotation and ignited once. This can be compared to a two-cylinder four-stroke engine, which has working strokes offset by 360 °. The working volume of the Wankel engine must therefore be calculated as follows:

with … chamber volume … number of runners

Source:

The Wankel engine has a relatively small size, which enables a high power density and low power to weight ratio . The reason for this lies in the more compact arrangement of the eccentric shaft and rotor compared to the piston, connecting rod and crankshaft in a reciprocating piston engine.

For the KKM 502 motor used in the NSU Spider , R = 100 mm,

e = 14 mm, b = 67 mm; the distance a between the rolling curve and the trochoid (equidistant) is 2 mm.

Materials and manufacture

The rotor is usually a precision cast part made of gray cast iron that does not require balancing . The further processing of the outer contours and sealing strip grooves takes place by means of broaching , turning and milling on several runners at the same time, which significantly increases the production throughput . Another possibility is the manufacture of the rotor from sheet metal, whereby the parts are then welded together (patent Audi). The housings are made of gray cast iron or aluminum, the side parts of nitrided or induction-hardened gray cast iron, of special steel alloys or of hypereutectic aluminum-silicon alloys .

Sealing system

Sealing strips , sealing strips and sealing bolts are available to seal the piston .

The piston is sealed on both sides to the side wall with two three curved sealing strips for the gas seal. The sealing strips are part of an axial seal and require flat and vertical side parts that expand unevenly due to different temperature and pressure conditions. The sealing strips are provided with spring elements to ensure that they are pressed on when the vehicle is started. After the engine has started, the gas pressure pushes them against the side wall. Made of pearlitic gray cast iron or steel, they slide over the running surfaces of the side parts.

The sealing strips on the runner edges, also called apex strips , run with the chamber width b on the trochoid path and seal the chambers against one another. They lie in axial grooves and are each enclosed by two sealing bolts at the corners. The sealing strips can be made in one piece or in several pieces. The multi-part construction not only seals against the trochoid, but also against the side parts, which increases compression and thus also reduces consumption, especially in the lower speed range. The sealing bolts serve as a link between the sealing strip and the sealing strip. Sealing bolts as well as sealing strips are each applied to the side part by a spring. The sealing strips are also equipped with springs to enable the engine to start up. Then they are pressed by the gas pressure in the direction of rotation to the rear edge of the groove and against the track. Special designs in the foot part of the apex strips ensure that the apex strips are continuously pressed against the housing wall. They are made from sintered carbon (carbon-antimony or carbon-aluminum), gray cast iron, piston ring steel, FerroTiC (iron-titanium carbide sintered metal), silicon nitride, soft iron or pearlescent gray cast iron. All sealing parts have a lubricating film that must neither evaporate nor coke due to excessively high temperatures.

The sealing system of the rotary piston engine is not subject to any speed limitation as with a reciprocating piston engine.

control

In the Wankel engine, the gas exchange is controlled by slots, while the rotor simultaneously serves as a force-emitting and controlling component. The inlets and outlets can either be mounted in the housing chamber, then one speaks of circumferential inlet and circumferential outlet, or in the side parts, then one speaks of side inlet and side outlet, as it is e.g. B. is the case with the engine of the Mazda RX-8 . A combination of both inlet and outlet types is also possible, e.g. B. Mazda's early series rotary engines; there the side inlet was combined with a circumferential outlet.

The advantage of the circumferential inlet is that large cross-sections and thus long control times are possible, which leads to higher performance. This construction principle is therefore also the first choice for racing engines. The disadvantage of the circumferential inlet is the large overlap, which can lead to valve jerking. This is acceptable for a racing car, but unsustainable for a passenger car for reasons of comfort, which is why the NSU Ro 80 was always equipped with a damping torque converter and semi-automatic transmission. Because of the large overlap, the circumferential inlet is also not very suitable for charging because the inlet and outlet are open at the same time. The exhaust gas behavior is also relatively poor under partial load behavior.

The advantage of the side inlet and outlet is the lack of overlap. This means that there is no jerking of the valve and the engine is better suited for charging. Part-load behavior and emissions are also better and it harmonizes well with a manual transmission. The 90 ° deflection at the inlet results in better gas mixing. A disadvantage is the smaller inlet cross-section compared to a circumferential inlet, which is why the achievable power as a naturally aspirated engine is lower.

lubrication

As with conventional Viertakthubkolbenmotor often the engine mount pressure circulation lubrication , alternatively, also has mixed lubrication proven. The trochoid is supplied either with a mixture or with lubricating oil via a metering pump as loss lubrication. In the case of trochoid lubrication with a circumferential outlet, the mixing ratio is between 1: 400 and 1: 600; for motors with a side outlet, it is significantly higher. In the Mazda Renesis, some of the oil is pumped back into the oil sump through the side scraper rings.

cooling

Housing, rotor, side parts and sealing elements are cooled with water, fresh air or the gas mixture; the latter is preheated on its way through the piston.

Since the working cycles always take place in the same place in the Wankel engine, a steady temperature distribution develops with the result that constantly hot zones and constantly cold zones are formed, which are called hot arc and cold arc . The cooling should therefore ensure a temperature distribution that is as uniform as possible and lead to values that are compatible with the material. Cooling is used specifically for combustion in order to avoid spontaneous ignition of the mixture from hot spots. Spark plugs, for example, are hot spots.

The outlet area is located in the hot bend immediately next to the inlet zone and must be cooled so that the material stresses are kept within tolerable areas by means of appropriate cooling water or steel inserts. In reciprocating piston engines, the steel insert in the so-called regulating piston , in which the steel insert ensures that the piston expands in a controlled manner and does not expand too much, and that there is no need to allow excessive play between the piston and cylinder, is comparable to this. Not all rotary engines have a steel insert; For example, Audi NSU engines, Norton engines and derivatives do not have a steel insert. Today, modern rotary engines only cool the hot arc.

In order to reduce the heat losses, the temperature differences between the combustion chamber and the combustion chamber surface are reduced by providing a speed and temperature-dependent cooling of the rotor. For example, the rotor is only cooled from an oil temperature of 60 ° C and then only at speeds above 3,000 min −1 . The cooling oil supply is only released from an oil temperature of 60 ° C by an oil thermostat built into the eccentric shaft. Two spring-loaded ball valves provide at operating temperature that the runner only at a speed of 3,000 min -1 is cooled. In an air-cooled runner, such as that used by Norton, the intake air is passed through the runner or discharged through an ejector exhaust or a fan. This principle is still used today in the UAV UEL drone engines and Diamond Engines . Compared with mixture cooling, this has the advantage of a higher possible maximum output. In simple industrial engines, the piston is cooled with a mixture.

The choice of material for the trochoid ensures a more even temperature distribution. The use of an aluminum alloy for the housing results in a more uniform thermal load than a gray cast iron housing, which reduces the thermal expansion and thus leads to a reduction in stress.

ignition

In contrast to the reciprocating engine, the KKM ignites with every revolution of the eccentric shaft. The resulting high firing order places a heavy load on the spark plugs , especially since the cooling idle stroke is omitted. The Wankel engine shares this problem with the two-stroke engine . The invention of the multi-range candles led to considerable progress here. B. the copper core. In addition, through careful design of the candle position, the heat requirement can be reduced considerably. The Sachs engine of the Hercules W 2000 only needed a normal W175 spark plug from Bosch.

In general and with symmetrical combustion bowls, ignition takes place in advance, i.e. shortly before the narrowest point ( TDC ). If a second candle is used, one is at the beginning of the chamber and the second in or shortly after the constriction. Different effects of the candles on the combustion are noted. The leading candle reduces the pollutants in the exhaust gas and causes the engine to run more smoothly, while the lagging candle increases the power, as the flame front is accelerated by the squishy flow in the direction of the leading candle. As a result, you have the lowest fuel consumption if both candles ignite at the same time, but this leads to increased HC emissions . With series-production rotary engines, the lower candle is therefore often ignited first, which results in better exhaust gas values at the expense of fuel consumption. With the Renesis, Mazda has deviated from this strategy and ignites both candles in parallel at least at low load and idle. In connection with the most varied of trough shapes and arrangements, there is an almost confusing number of possibilities.

The arrangement of the candles also plays a key role in the emissions and consumption behavior. Basically, you reduce the expulsion of unburned mixture by using a double ignition or with a single candle in the late trailing position (late trailing = the trailing candle is arranged far above the constriction); This reduces consumption by around 30 percent compared to the earlier versions. The use of two spark plugs reduces the time sequence of the ignition intervals to microseconds, which is why up to a certain speed you work with two ignitions, above this only one ignition is used. The second candle is mandatory for aircraft engines anyway because of the higher reliability that it entails. The Mazda 787B had a triple-ignition Mazda 26B engine at the 1991 Le Mans 24-hour race . The third spark plug on the 26B ignites the mixture on the upper side of the chamber before the squeeze flow sets in, resulting in better chamber burnout and lower fuel consumption.

Efficiency-performance characteristics-consumption

The cycle of the Wankel engine corresponds to the Otto process , which consists of two isentropes and two isochors ; it is also called the same-space process. The isochoric heat supply is assumed because with external ignition the energy is suddenly released and the volume hardly changes. The ideal thermal efficiency is:

With the ideal efficiency becomes:

Where = 1.4 ( specific heat capacity at constant pressure, specific heat capacity at constant volume). The efficiency depends solely on the compression ratio .

The following applies to isentropic compression: (1: start of compression, bottom dead center, largest volume; 2: end of compression, top dead center, smallest volume)

- and

As with all Otto engines , compression is desirable in the Wankel engine and leads to a higher degree of efficiency, but it is limited by the compression end temperature T 2 , which must be below the auto-ignition temperature of the mixture. The auto-ignition temperature of a Wankel engine is usually higher than that of a gasoline engine, so that Wankel engines tend to use less knock-resistant fuel, i.e. petrol with a lower octane rating, with the same compression .

The real process differs from the idealized one for a variety of reasons. If the indicator diagrams are recorded, the actual pressures p i and volume are reproduced, from which the indicated efficiency can be determined and represented in diagrams. It applies to the specific parameters in each case, such as speed , compression ratio, etc. The efficiency of a Wankel engine is shown here using an Audi NSU EA871 as an example for gasoline and hydrogen operation.

The formula for the indicated power [kW] is:

with the indicated pressure , the chamber volume , the number of pistons , the speed and the number of working strokes per crankshaft revolution / eccentric shaft revolution (with a rotary engine ).

The shaft power is obtained from torque measurement for HKM and KKM:

with in [Nm] and in [1 / min] the adjusted formula results in the power in [kW]:

The mechanical efficiency is the ratio of the shaft power to the indicated power :

As can be seen, the performance of an engine can be improved by using higher pressures or higher speeds. According to the illustration, the torque is generated by the chamber pressures with the associated piston crown surfaces. The forces F p always act in the center of the eccentric and generate the torque M d with the corresponding angle-dependent lever arm of the eccentricity e .

The maximum compression ratio of the engine is determined by the K-factor and can therefore be modified structurally. The real compression ratio is then set with the trough. The speed is limited by the wear of the sealing surfaces, problems with the degree of filling and the combustion time of the mixture.

Advantages and disadvantages compared to the reciprocating engine

advantages

- The Wankel engine has only a few moving parts, usually two rotors and an eccentric shaft, which, due to their compact design, require a comparatively small amount of space.

- The gas control works without valves and the associated elements such as camshaft, tappets, valve clearance compensation and rocker arm, which means that the engine achieves a higher power-to-weight ratio ( power -to-weight ratio ) than a four-stroke reciprocating engine of comparable performance.

- Since all moving parts either rotate (eccentric shaft) or rotate around their center of gravity, which revolves on a circular path (rotor), a rotary engine can be completely balanced. The result is a smooth and low-vibration run even with only one disc.

- The engine has a more uniform torque than four-stroke reciprocating engines of the same power because there are no reciprocating parts to be accelerated.

- Since the inlet and outlet are spatially separated from the combustion chamber, the rotary engine is very well suited for operation with hydrogen . This also allows the use of low octane fuels without ringing .

- It is better suited for stratified charge operation than a reciprocating engine, as the mixture does not homogenize. It can therefore also be operated with ideal ignition times, which reduces the wall heat loss compared to reciprocating piston stratified charge engines. Reciprocating stratified charge engines have to be operated with too early and therefore non-ideal ignition times because of the threat of mixture homogenization.

- The specific fuel consumption of the Wankel engine is lower compared to the two-stroke petrol engine (but higher compared to the four-stroke petrol engine).

disadvantage

- The Wankel engine has an unfavorably shaped combustion chamber and many heat-dissipating surfaces, which is why it has a poorer thermal efficiency compared to the reciprocating piston engine. In addition, the ratio between surface area and volume is also very poor, especially at the tips of the gussets, which leads to greater heat losses and the mixture cools down significantly, which also lowers the thermal efficiency.

- The resulting squeeze flow in the area of the constriction accelerates the combustion below the candle and thus a good burnout of the chamber is achieved, but the mixture above the candle is ignited only with difficulty or not at all. However, this only has an effect on engines with a circumferential outlet and homogeneous mixture formation; the unburned fat residual gas core is expelled via the peripheral outlet. With stratified charge there is only air in the affected area, and with the side outlet the rich old gas core remains in the chamber.

- The sealing surfaces of the rotary engine are considerably longer than in a reciprocating piston engine and lead to higher pressure losses.

- For the reasons mentioned above, the specific fuel consumption of the Wankel engine is higher than that of the four-stroke piston engine .

- The exhaust behavior of the rotary engine is very bad. As a result of the incomplete combustion due to the unfavorably shaped combustion chamber, it emits a large number of hydrocarbons (HC) in particular . The emission of nitrogen oxides (NO x ) is only about 40% compared to the reciprocating engine; however, the emission of carbon monoxide (CO) is roughly comparable to that of a reciprocating piston engine.

History of the rotary engine

History of rotary piston machines

The history of rotary piston machines began in the 16th century with the construction of water pumps , which were already designed in a manner similar to today's rotary and rotary piston machines . The kinematics of rotary piston machines, in which the moving parts only rotate around the center of gravity , was easier to master, which is why it was still a while before the first rotary piston engine.

In 1588 the Italian engineer Agostino Ramelli published various water pumps, which were rotary and rotary piston-type circulating machines.

In 1636, a gear pump invented by Gottfried Heinrich zu Pappenheim is said to have supplied a fountain with water for the first time. The gear pump, a regular rotary piston machine, still serves as an oil pump in most car engines today.

James Watt , who had decisively further developed the reciprocating piston steam engine and helped it achieve its breakthrough, tried again and again with rotary piston engines throughout his life until he constructed a rotary piston-like rotary piston steam engine in 1782. William Murdoch modified Pappenheim's gear pump in 1799 and provided the tooth head flanks with wooden sealing strips. With this steam engine he drove drills and lathes in his workshop.

In 1846 Elijah Galloway built the first displacement-forming steam engine that had no internal or external comb engagement . However, due to the lack of sealing elements, it could not hold its own against the now well-sealed reciprocating piston steam engines. In 1895, Philander and Francis Roots developed a rotary piston machine that is still in use today and named after them: the Roots compressor . Charles Parsons , the inventor of the steam turbine , built one of the first functional rotary piston machines with lifting engagement in 1884. The functionality of the piston ring was still unknown at the time.

In 1923, Wallinder & Skoog in Sweden created a KKM with a pentagonal runner.

In general, the seals caused problems, and it was more than two decades before Felix Wankel developed a rotary piston engine together with NSU .

Development of the Wankel engine from 1932 to 1960 and first run

Felix Wankel carried out tests on a rotary valve control for a four-stroke reciprocating piston engine and, when these failed, decided to specifically research the engine's sealing. In the course of these investigations, he was able to prove that it is the gas pressure that ensures the seal. His findings led to a significant improvement in the piston ring seal and after 25 test devices he succeeded in effectively sealing the rotary valve control, which laid the foundation for the development of the rotary engine.

In 1932 Felix Wankel designed the rotary piston machine DKM 32, which later only ran for a short time, but as a compressor delivers an overpressure of 5 bar at 1000 min −1 , which is due to the first spatial sealing limit.

In 1936 he went to the German Aviation Research Institute (DVL) and quickly got a five-cylinder radial engine from Siemens & Halske (S & H) up and running. The later head of engine development at Daimler-Benz , Wolf-Dieter Bensinger, presented his report to State Secretary Erhard Milch , who then went to Reich Minister Hermann Göring . "This man is to be supported generously" was his instruction, whereupon Felix Wankel founded his own research workshop with his Wankel test workshop (WVW) in Lindau . From 1936 to 1941 he successfully developed rotary valve controls for aircraft engines from S&H, Junkers , BMW and Daimler-Benz.

Tests carried out in 1941 with high oil pressures of up to 1000 bar showed new ways of using plain bearings. The DVL and WVW signed a series of option agreements with the most important companies at the time. The end of the war in early May 1945 interrupted the planned series production of rotary vane motors. The WVW in Lindau were dismantled by the French occupying forces .

In 1951, Felix Wankel resumed his collaboration with Goetze AG (today Federal-Mogul ) in Burscheid with the newly created Technical Development Center (TES) in his Lindau house . This was followed by the conclusion of a research contract with NSU for the development of rotary valve controls, which was shortly expanded to include rotary piston machines. Felix Wankel was now looking for a high-speed rotary piston machine. In 1954 he negotiated with Borsig to use the DKM 53 as a compressor. Borsig and NSU agreed on a demarcation of interests, according to which NSU worked on the area of power machines and Borsig the area of work machines .

In 1956, NSU engineer Hanns-Dieter Paschke developed the rotary piston compressor DKK 56 from the test air engines (arena machines), which charged a 50 cm³ two-stroke NSU Quickly engine to an outstanding 13.5 hp and set the world record at 196 km / h a Baumm deckchair II made possible. The type of loader was kept secret, which led to all sorts of speculation.

On February 1, 1957, the DKM 54 ran for the first time only briefly in the NSU test department TX; After the mixture and the ignition were adjusted differently, the engine literally began to run smoothly. With the DKM 54, the chamber (external rotor) and the internal rotor rotate. The force-emitting element is the external rotor, the internal rotor serves only as a pure shut-off and control part. In April 1957 they switched from alcohol to gasoline. The motor still achieves the same performance and runs more smoothly at the same time. With the mixture cooling, more than 20 hp cannot be achieved with the 125 cm³ engine. The rotating inner rotor was provided with a water cooling system that was developed in the TES Lindau. In the same year, the NSU engineer Hanns-Dieter Paschke began to design the more simply constructed KKM 57P; For the first time, the external rotor has now been stopped. So that Wankel did not find out about it, this was done in strict secrecy, because he would have prevented it. Felix Wankel later said angrily about the KKM 57: "You made a plow horse out of my racehorse." NSU chairman Gerd Stieler von Heydekampf countered: "If we at least had the plow horse!" That was the relationship between Wankel and NSU Reached low point. The tests with the DKM 54 were discontinued in 1958, because the principle had shown its functionality. On July 7, 1958, a rotary piston engine ran for the first time with the KKM 57P.

The rotary engine in vehicle construction from 1960 until today

Development from 1960 to 1970

Two years later, in 1960, a car was powered by a Wankel engine for the first time , an NSU Prinz III was powered by a KKM 250.

On January 19 of the same year, the KKM 250 was presented to the public for the first time at an event organized by the Association of German Engineers (VDI) at the Deutsches Museum in Munich . Now the KKM 400 was developed, which was designed as a car engine from the start. In the same year he was built into a sports prince. Other converted NSU Sport-Prinz followed, in which the rotary engine completed a million test kilometers.

In 1962, on February 16, the so-called “Rattermark Conference” took place. It became necessary because the chrome layers flaking off the running surfaces led to frequent engine failures. Trials with lighter sealing strips led to success, and in September the KKM 150 was the first Wankel engine to go into series production. He also used sintered carbon sealing strips for the first time, which solved the chatter problem for the time being. The KKM 150 was used to drive a water ski towing device called Skicraft. The engine also served as an auxiliary drive, as a so-called lull pusher for sailing boats.

In 1963, the first mass-produced car with a rotary engine, the NSU Wankel Spider , was presented to the public at the IAA , and Mazda exhibited a test car with a two-disc engine at the Tokyo Motor Show . In October 1964 the NSU Wankel Spider went into series production. The KM 37 was the first Wankel engine to be mass-produced by Fichtel & Sachs . At the same time, the KM 914 with a chamber volume of 300 cm³ was created as a stationary engine and as a drive for snowmobiles , in which it was installed by Fichtel & Sachs in 1965. In the same year NSU exhibited the two-disc engine type 506/509 at the IAA.

In 1967 the NSU Ro 80 was presented to the public at the IAA in Frankfurt. On April 21st, NSU and Citroën founded the joint subsidiary Comotor in Luxembourg. Mazda went into series production with the Cosmo Sport in May, making it the first automaker to produce a car with a two-disk engine. In 1969, Citroën began Operation M35, selling Citroën M35s to around 300 handpicked customers , who together covered over 30 million test kilometers. Mercedes-Benz presents the C-111-I with a three-disk engine at the IAA in Frankfurt. In the fall, the Ro-80 engine was switched from double to single ignition and a high-voltage capacitor ignition was installed. The NSU Marine Ro 135 marine engine with dual ignition was built in series.

Development from 1970 to 1980

Mercedes-Benz exhibited its C-111-II at the Geneva Motor Show in 1970 . The body had been redesigned and instead of a three-disc engine, a four-disc engine was tested; subsequently, however, Mercedes decided against installing rotary engines. The British motorcycle manufacturer BSA tested a BSA A65 with a rotary engine. Hercules exhibited the W 2000 prototype at IFMA , using a modified KM 914B snowmobile engine from Fichtel & Sachs as the engine. The Graupner company introduced the model engine OS Wankel (Ogawa Seiki) into the series.

In 1971, BSA / Triumph developed their own air-cooled two-disc engine, which was built into a Triumph Bandit frame. Thermal exhaust gas cleaning and a speed warning system are introduced in the Ro 80.

In 1972 Ingersoll Rand manufactured the rotary engines IR-2500 and IR-5000, the engines with the largest chamber volume to date of 41 liters. Fichtel & Sachs introduced the second generation of engines, the KM 3 and the KM 24; the latter replaced the KM 914 as a snowmobile drive. Mazda produced 155,500 rotary-engine cars that year. VW withdrew from the contract signed by NSU and Citroën, and Comotor became the sole subsidiary of Citroën. Mazda produced around 240,000 rotary-engined cars in 1973, making the total for 500,000. Car produced with a rotary engine. OMC started under the label Evinrude and Johnson with a four-disc engine in the open boat racing class. Evinrude launched rotary engine snowmobiles in the same year. After Johnson and Evinrude dominated the open class in boat races, rotary engines were excluded from the competition for 1974. In September, Citroën began series production of the Citroën GS Birotor . Yanmar Diesel manufactured three types of outboard engines with rotary engines. Rhein-Flugzeugbau installed a 60-hp Fichtel & Sachs twin-disc rotary engine in the Sirius II motor glider . The Comotorwerk was inaugurated in Altforweiler . VW and Citroën reached a development agreement for the EA871, which was intended for the large Citroën models. Ford canceled the license agreement because Curtiss-Wright demanded a license fee of over $ 100 million; Ford tried to take over Mazda in return.

In 1975 Werner Wieland received patents for his Wieland motor , made from welded sheet metal parts, which was tested at Audi AG in Neckarsulm and was built over 250 times. This version of the Wankel engine is 22% lighter than an engine made from cast parts and offers advantages in terms of cooling and manufacturing costs. This variant did not get beyond the test use in some in-house Ro 80s.

In 1976 the Van Veen OCR 1000 motorcycle was created by the Dutch motorcycle specialist Van Veen ; he used the Comotor Wankel engine (Citroën) and equipped it with an electronic map- controlled ignition from Hartig . OMC stopped production after 15,000 engines and withdrew from the snowmobile market. Hercules brought out the improved Hercules 2000 injection with the more powerful KC-27 rotary engine.

The production of the Ro 80 was stopped at the end of the 1977 model year after 37,450 vehicles were built within ten years; Mazda built around 50,000 rotary engine cars in the same year. The RFB prototype Fantrainer 300 was presented to the public on December 14th. Two Audi NSU EA871A Wankel engines, whose lubrication system is suitable for aerobatics, served as the drive.

Mazda introduced the twin-disc KKM RX-7 SA into series production in 1978, and John Deere took over the rotary development from Curtiss & Wright. After BSA / Triumph went bankrupt, BSA rotary engine development was transferred to Norton .

Development from 1980 to today

In 1985, OMC sold its Wankel division to the Canadian developer and inventor Paul Moller . Norton produced the Interpol 2 in series for the British police . Teledyne Continental Aircraft Products developed aircraft engines based on Norton engines. Due to product liability in the USA, the project was later abandoned.

In 1986, Mercedes-Benz acquired Felix Wankel's institute for 100 million Deutschmarks. In 1988 Norton produced the Norton Classic , based on the Interpol , the first rotary motorcycle for the free market. The Interpol 2 was replaced in 1989 by the Norton Police Commander , a civilian version was built as Norton Commander .

In 1990 Mazda produced the Eunos Cosmo, the first production car with a three-disc rotary engine. Mazda won the Le Mans 24-hour race in 1991 with the Mazda 787B and starting number 55 . The racing car was powered by a four-disc rotary engine. In 1992 Mazda launched the RX-7 FD. In the same year, UEL emerged from a management buy-out of Norton's former development department. Midwest Engines was founded and manufactured rotary engines for manned aircraft based on Norton engines.

Carlos Fernandez Pello from the University of Berkeley developed a miniature rotary engine as part of Micro-Electro-Mechanical Systems (MEMS) and presented it in 2001. Mazda built the last RX-7 in autumn 2002, of which a total of 811,634 vehicles were sold.

The company Wankel Super Tec was founded under the direction of Ernst Sigmund, a former rector of the University of Cottbus, on February 12, 2003 in Cottbus and continues the development of rotary piston engines as a result of Felix Wankel's employees. This foundation has brought the rotary engine back into the focus of interest for various applications where a low power-to-weight ratio, great smoothness and low background noise are important.

From April 2003 to March 2006 Mazda produced the RX-8 in series with a quantity of 148,317. Since March 23, 2006, Mazda has been leasing the Mazda RX-8 Hydrogen RE , the first production car to use hydrogen as fuel, in Japan . On August 10, 2006, Freedom Motors achieved the SULEV emissions target for zero-emission vehicles with its Wankel engines .

Mazda showed the Premacy Hydrogen RE Hybrid at the 2007 Tokyo Motor Show . The improved Renesis 16X rotary engine was also presented to the public. The Premacy Hydrogen RE Hybrid was leased from March 25, 2009 in Japan.

At the Geneva Motor Show 2010, Audi showed the A1 e-tron, an electric vehicle in which a single-pane Wankel serves as a range extender. The Wankel is supposed to work here at a constant speed of 5000 min −1 close to its maximum efficiency. The compact Wankel engine is located under the trunk floor in this vehicle.

In Germany in 2010, the Kirchberg- based company Wankel AG and the Aachen- based company Aixro offered Wankel built-in motors.

Efforts to develop environmentally friendly drives lead to a renaissance.

Mazda plans to offer an electric car with a rotary engine range extender for 2020 .

Wankel diesel

Engines that work according to the diesel process

There have also been attempts to carry out the diesel process with a Wankel engine, although the rotary piston engine is poorly suited for this due to its special features. In the 1960s, Rolls-Royce developed a tank engine with the R1 to R6 series, with two Wankel disks connected in series. The rotary piston of the low pressure stage pre-compresses for the high pressure stage. Both pistons are connected via a gearbox, but the fuel is only injected into the high-pressure stage. In 1969 the best value for specific consumption was 180 g / kWh. Two coupled units of this version were designed for an output of 350 hp (261 kW) at 4500 rpm, in fact the engine could only run with externally supplied, pre-compressed air and achieved an output of only 180 hp (134 kW) on the test bench.

The high peak pressures and correspondingly high stresses that occur in the chamber wall turned out to be a problem during development. The problem was solved by integrated tie rods, which now absorb the shear forces. The so-called warm cycle creep of the aluminum used as the chamber material could thus be avoided. The greatest difficulty with the Wankel diesel engine was to find a suitable shape of the combustion chamber that would match the injection jet and, at the same time, to achieve a high compression ratio that would enable compression ignition, one of the main features of the diesel engine. For all documented prototypes that work according to the diesel process, externally pre-compressed air had to be supplied. There is no known Wankel diesel engine that can run safely on its own.

Engines that do not use the diesel method

In 1992, the former employee of Felix Wankel, Dankwart Eiermann, bought Wankel Rotary GmbH back from the LONRHO Group together with Jürgen G. Bax. In the following years the company developed a Wankel engine suitable for operation with diesel fuel with spark ignition (i.e. with spark plug) and direct injection, using methods known since the 1960s (including the F M method ); the engine therefore does not work according to the diesel process, but only with the fuel common to diesel engines. The use of direct injection and spark ignition has overcome many of the previous difficulties associated with using diesel fuel, such as poor combustion and low efficiency. The liter output of prototypes was up to 110 kW with consumption comparable to modern reciprocating piston direct injection engines. Despite this promising development, Wankel Rotary GmbH had to file for bankruptcy in 2000. The patent and trademark rights were acquired by Mario Häberer in 2001.

Licensee

| date | Licensee | country | License |

|---|---|---|---|

| 10/21/1958 | Curtiss-Wright Corp. | United States | without restriction |

| December 29, 1960 | Fichtel & Sachs AG | D. | Industrial engines, boat 0.5-30 HP |

| 02/25/1961 | Yanmar Diesel Co. Ltd | JP | Gasoline and diesel engines, 1-100 hp, 1-300 hp |

| 02/27/1961 | Mazda | JP | Petrol engines 1–231 HP for land vehicles |

| 04.10.1961 | Klöckner-Humboldt-Deutz AG | D. | Diesel engines without restriction |

| 10/26/1961 | Daimler-Benz AG | D. | Petrol engines 50 hp and up |

| 10/30/1961 | MAN AG | D. | Diesel engines without restriction |

| 11/02/1961 | Friedrich Krupp AG | D. | Diesel engines without restriction |

| 03/12/1964 | Daimler-Benz AG | D. | Diesel engines without restriction |

| 04/15/1964 | SpA Alfa Romeo | IT | Petrol engines from 50–300 HP for cars |

| 02/17/1965 | Rolls-Royce Motors Ltd. | GB | Diesel and hybrid engines 100–850 hp |

| 02/18/1965 | VEB IFA | GDR | Otto engines 0.5-25 HP and 50-150 HP |

| 03/02/1965 | Dr.-Ing. H. c. F. Porsche KG | D. | Gasoline engines from 50-1000 hp |

| 03/01/1966 | Outboard Marine Corporation | United States | Petrol engines 50–400 hp |

| 05/11/1967 | Comotor SA | L. | Gasoline and diesel engines 40–200 hp |

| 09/12/1967 | Graupner | D. | 0.1-3 HP model motors |

| 08/28/1969 | Savkel Ltd. | IS | Petrol engines from 0.5–30 HP industrial engines |

| 10/01/1970 | Nissan Motor Company Ltd | JP | Gasoline engines from 80-120 hp |

| 11/10/1970 | General Motors | United States | Everything except airplane engines |

| 11/24/1970 | Suzuki | JP | Gasoline engines from 20–60 hp for two-wheelers |

| May 25, 1971 | Toyota | JP | Petrol engines from 75–150 hp for cars |

| 04.10.1971 | Kawasaki Heavy Industries | JP | Gasoline engines 20–80 HP for motorcycles |

| 11/29/1971 | Ford-Werke AG, Cologne | D. | Gasoline engines 80-200 hp (canceled in 1974) |

| 07/25/1972 | BSA Ltd. | GB | Petrol engines 35–60 HP for motorcycles |

| 29.09.1972 | Yamaha engine | JP | Gasoline engines 20–80 HP for motorcycles |

| 02/07/1973 | American Motors Corporation | United States | Gasoline engines 20–200 HP |

The patents for the rotary engine have now expired, which is why licenses are no longer required to build it. However, since the naming rights lie with the VW Group, the corresponding Mazda engines were no longer referred to as rotary piston engines but as rotary piston engines.

Vehicles with a rotary engine

Automobiles

Series vehicles

- NSU Wankel Spider (1964–1967), first production vehicle with a rotary engine.

- Mazda 110 S Cosmo Sport (1967–1972), the first production vehicle with a twin-disk engine.

- NSU Ro 80 (1967-1977)

- Mazda R100 (1968-1975)

- Mazda R130 (1969–1972) Coupé with 13A rotary engine.

- Mazda RX-2 (1971-1974)

- Mazda RX-3 (1972-1977)

- Mazda RX-4 (1972-1977)

- Mazda Rotary Pickup (1973–1977), sold in the US only.

- Mazda Parkway Rotary 26 (1974–1976), the first bus with a rotary engine.

- Mazda Roadpacer (1975-1977)

- Mazda RX-5 (1975-1981)

- Mazda RX-7 (1978-2002) series SA (FB), FC, FD.

- Mazda Cosmo AP RX-5 (1981-1990)

- Eunos Cosmo (1990–1995), the first production vehicle with a three-disk engine.

- Mazda RX-8 (2003-2012)

Prototypes and small series

- Citroën M35 (1969–1971), purely a test vehicle, only 267 units were built.

- Mercedes-Benz C 111 (prototype 1969–1971) three-disc and four-disc engines

- Chevrolet prototypes XP-895 and XP-897GT (1972)

- Citroën GS Birotor (1974–1975), 847 units manufactured.

- Mazda racing cars: 717C , 727C , 737C , 757 , 767 and 787B (1991 Le Mans 24 Hours winners )

- Mazda concept vehicles: RX-8 Hydrogen RE (2004), 5 HRE (2005) and Furai (2008).

- Flying cars M200 and M400 of the company Moller

In the 1960s and 1970s, many other manufacturers experimented with rotary engines, including Škoda (1964–1967), Trabant and Wartburg (1961–1969), Nissan (1972) and Audi with the Audi 100 C2 (1976–1977).

motorcycles

Although all major motorcycle brands were working on the integration of a rotary engine for motorcycles, no significant sales figures could be achieved. The reasons were technical problems with engine installation and high development costs. The first production motorcycle to be equipped with a rotary engine was the Hercules W 2000. Although it performed well in comparative tests with direct competing models, it was not widely accepted by the market; 1780 copies were built.

- Hercules W 2000 "vacuum cleaner"

- Hercules KC31 in the GS 250 frame

- Suzuki RE 5

- Van Veen OCR 1000

- Motoprom

- MZ prototypes

-

Norton Motorcycles

- Norton P41 "Interpol 2"

- Norton P43 "Classic"

- Norton P52 "Commander Police"

- Norton P53 "Commander Civilian"

- Norton P55 "F1"

- Norton P55B "F1 Sports"

- Norton NRS 588

Watercraft

- Avenger sport boat with two Marine Ro 135

- Ski-craft water-ski pulling device and slider

- Racing boats OMC ( Evinrude / Johnson )

- Hiss 68

- Hiss 74

Planes

- Citroën RE2 helicopter with Citroën RMR07V rotary engine

- RFB AWI-2

- RFB Sirius II with Fichtel & Sachs twin-disc rotary engine

- RFB Fantrainer Two-seat training aircraft with coat screw prototype with two EA871A.

- Rhein-Flugzeugbau Fanliner Two -seat sports machine with an EA871A

- Alexander Schleicher ASK 21 mi , ASH 26 E , ASW 22 BLE and ASH 25 Mi , ASH 30 Mi , ASH 31 Mi , ASG 32 Mi with single-disc Diamond Engines Wankel engine

- Disc SF 24 with Fichtel & Sachs 20 kW Wankel engine

- Katana with Diamond Engines Wankel engine GIAE-110R.

Unmanned aircraft, drones, UAV

The low vibration for high-resolution camera recordings is interesting here.

- Blue Horizon II UAV manufacturer EMIT

- Camcopter S-100 with Diamond Engines AE-50R, manufacturer Schiebel (Austria)

- Crecerelle UAV, manufacturer SAGEM

- Darter UAV, manufacturer Silver Arrow

- Deltron III UAV, manufacturer TESTEM

- Dragon UAV, manufacturer Matra

- Galileo UAV with UEL AR-682

- GLOV UAV manufacturer Accurate Automation Corp.

- Goldeneye UAV with UEL AR-741

- Harpy UAV, manufacturer IAI

- Hellfox UAV, manufacturer Mi-Tex

- Hermes 180 with UEL AR-74-1000, 10 hours flight time, manufacturer Silver Arrow

- Hermes 450 and 450S with UEL AR 80-1010 , 20 hours and 30 hours of flight time, manufacturer Silver Arrow

- i-Foile UAV

- ISIS with UEL AR-8010

- Lark UAV, manufacturer Kentron

- Marula UAV, manufacturer SAGEM

- Night Intruder 300 KAI

- Nishant UAV, manufacturer ADE

- Phantom Medium Tactical UAV

- Pioneer RQ2A with UEL AR-741, manufacturer PUI

- Pioneer RQ2B with UEL AR-741, manufacturer IAI

- Prowler I, manufacturer GA-ASI

- Scout UAV with UEL AR-801 manufacturer IAI

- Seabat UAV, manufacturer Orion

- Sea Scout with UEL AR-801

- Searcher II manufacturer IAI

- Shadow 200 with UEL AR-741, Shadow 200B with UEL AR-741, Shadow 400 with UEL AR-741, Shadow 600 with UEL AR-801, manufacturer AAI

- Sikorsky Cypher and Cypher II with UEL AR-801

- Skyeye with UEL AR 80-1010, manufacturer BAE Systems

- Sniper UAV, manufacturer Silver Arrow

- Starbird UAV, manufactured by Northrop Grumman

- STF-9A UAV, manufacturer Daedalus

- TPPV-1 Doysae UAV, manufacturer KAI

- UAV-X1, manufacturer TAI

- Vixen UAV, manufacturer Mi-Tex

Sports use

In order to establish the rotary engine in the engine world, the NSU and Mazda teams took part in various car races and were able to record some victories that, due to the system, do not allow any conclusions to be drawn about the engine alone. It was the German rally championship (1969), the 24-hour boat race in Rouen (1966), German mountain champion of all classes (1967 and 1968), the victory in the 24-hour race at Le Mans (1991) in which the engine consumed around 285 g / kWh in the range of the maximum torque, and also victories in the American and Australian touring car championships. Victories were also recorded in the open class of racing boats (1973). From 1980 to 1986 Mazda was the sole supplier of rotary engines for the South African Formula Atlantic Championship , in which British Formula 2 chassis were used.

Norton equipped motorcycles with rotary engines and achieved some success in the racing sector. For example the British Superbike Championship , twice the Powerbike International and in 1992 the Tourist Trophy on the Isle of Man with the RCW588 and driver Steve Hislop .

Karts have also been powered by rotary engines since the 1990s . The advantages lie in the low weight. The output is up to 30 kW with a chamber volume of less than 300 cm³ and a weight of around 17 kilograms. The engine power is delivered to the rear axle via a centrifugal clutch and an input gear.

Other uses

The rotary engine is also used as an aircraft drive . The Alexander Schleicher GmbH builds a Diamond Engines Einscheibenmotor into their folding driving the ASK 21 Mi ASH 26 E and ASH 25 Wed. The VLA (very light aircraft) two-seater Katana will in future be equipped with the 110 hp twin-disc rotary engine from Diamond Engines , and the Aeriks 200, also a two-seater from Manno , Switzerland , will also receive a Diamond rotary engine GIAE-110R . The company Wankel Super Tec in Cottbus has developed a positive-ignition diesel rotary engine, which in terms of consumption comes close to the highly optimized HKM TDIs. This is to be used in aircraft.

One variant is the "Wankel positive-ignition diesel", a multi-fuel engine that works with external ignition to drive so-called drones . Although diesel is injected here as fuel, the typical diesel auto-ignition is not used. The English company UAV EL is currently the world market leader in drone rotary engines.

Due to the spatial separation of the intake and combustion chambers, the rotary engine is particularly suitable for burning hydrogen (hydrogen operation) and similar highly flammable fuels (natural gas, LPG, etc.), as the gas mixture does not prematurely adhere to hot components (such as exhaust valves and the combustion chamber surface ) can ignite. There is a spatial separation of the compression and combustion chambers, which increases the knock resistance compared to the four-stroke reciprocating engine . Mazda is currently testing operation with hydrogen in the RX-8 HRE and Mazda 5 HRE. This is where the rotary engine benefits from its special combustion chamber shape.

Ingersoll-Rand built gas rotary engines in series for gas pumping stations between 1972 and 1986 .

Norton , Suzuki and Yamaha tried their hand at motorcycles, Sachs built a modified engine into the Hercules W 2000.

In-house developed rotary engines were used in the snowmobiles of the OMC company, other snowmobile manufacturers used F&S rotary engines.

The companies Italsystem and Aixro GmbH built rotary engines for racing karts and Freedom Motors for water scooters . Aixro GmbH also for paramotor and unmanned aerial vehicles. Fichtel & Sachs built rotary engines for lawnmowers and emergency power generators. In 1975 a Dolmar chainsaw was powered by a KMS 4 from Fichtel & Sachs. In the Stihl Timbersports Series , a forest workers' competition, rotary engines from Aixro GmbH were sometimes used to drive heavy chainsaws (output> 44 kW) in the “Hot Saw” discipline .

In 1997, small, compressed gas - powered , one-way rotary engines were used to drive belt tensioners , which VW installed in the Passat and Mercedes in its S-Class . The Sachs KKM 48 rotary engine was also installed in the twin anti-aircraft gun 20 x 139 RH 202 from the manufacturer Rheinmetall, which was used by the Bundeswehr Air Force and in other European countries until 1990 .

The company Wankel SuperTec GmbH developed a serial hybrid drive for the Volocopter helicopter from the company e-volo GmbH.

Motor vehicle tax (in Germany)

Vehicles with rotary engines are taxed according to the gross vehicle weight like trucks.

The amount of vehicle tax for cars in Germany is based on the engine size . The NSU RO 80 with almost 1000 cm³ chamber volume and 86 kW would have meant a tax of only 144.00 DM / year had the displacement tax of 14.40 DM / 100 cm³ applied at the time. In order not to favor rotary engines over reciprocating engines, the tax authorities first wanted to double the chamber volume, since a car with 86 kW at that time corresponded to a reciprocating engine displacement of 2 liters. After a number of negotiations, however, an agreement was reached on the application of the truck tax. The tax is based on the total weight permitted under traffic law. Costs with a permissible total weight up to 2000 kg: EUR 11.25 per 200 kg vehicle weight.

Others

- The postage stamp 50 years Wankel engine with a value of 145 cents was issued on January 2, 2007 by Deutsche Post

- The Autovision Museum in Altlußheim is showing the world's first permanent rotary engine exhibition

- Walter Frey in Gersthofen owns one of the world's largest collections of vehicles and devices with Wankel engines.

literature

- Felix Wankel: Classification of rotary piston machines. DVA Fachverlag, Stuttgart 1963.

- Kenichi Yamamoto: Rotary Engine. Sankaido, Tokyo 1981.

- Richard F. Ansdale: The Wankel Engine . Construction and mode of operation. 1st edition. Motorbuch Verlag, Stuttgart 1971, ISBN 3-87943-214-7 .

- Wolf-Dieter Bensinger: Rotary Pistons - Combustion Engines. Springer-Verlag, Berlin / Heidelberg 1973, ISBN 3-540-05886-9 .

- Andreas Knie: Wankel courage in the auto industry. Edition Sigma, ISBN 3-89404-145-5 .

- Dieter Korp: Protocol of an Invention: The Wankel Engine. ISBN 3-87943-381-X .

- Claus Myhr: NSU Ro 80 and Wankel Spider 1964–1977. ISBN 3-922617-49-2 .

- Marcus Popplow: Motor without a lobby? ISBN 3-89735-203-6 .

- Ulrich Knapp: Wankel put to the test. ISBN 3-8309-1637-X .

- John B. Hege: The Wankel rotary engine: A History. ISBN 0-7864-1177-5 (English).

- Ludvigsen Publications: Wankel Engines A to Z. ISBN 0-913646-01-6 .

- BMF report on the positive-ignition diesel rotary engine (PDF file for download, with finished part drawings, temperature and load diagrams in 3D; 12.19 MB).

- M.4-Rotor Rotary Engine for Le Mans (26B report, .doc file for download, English).

Web links

- Publications on the subject term Wankel engine in the catalog of the German National Library

- Search for a rotary engine in the German Digital Library

- Search for a rotary engine in the SPK digital portal of the Prussian Cultural Heritage Foundation

- Pictures of cars with rotary engines on Heise

Animations

- Housing shape from the rolling curve (Java required; entering 18 gives the housing shape of the rotary engine)

Further information

- der-wankelmotor.de (information about the rotary engine)

- MEMS Rotary Engine Power System (English)

Individual evidence

- ↑ maz-online.de: Without Paschke there would be no "rotary engine"

- ↑ Wolf-Dieter Bensinger: Rotary piston combustion engines , Springer, Berlin / Heidelberg 1973, ISBN 978-3-642-52174-4 , p. 65f.

- ↑ MTZ 10/2002 Volume 63, Pages 810-812

- ↑ SAE 2004-01-1790 Developed Technologies of the New Rotary Engine (RENESIS)

- ↑ SAE Paper SAE 920309 Mazda 4-Rotor Rotary Engine for the Le Mans 24-Hour Endurance Race; Table 1 and page 7.

- ↑ Andsdale The Wankel Engine K = R / e page 81

- ↑ Techniklexikon https://www.der-wankelmotor.de/Techniklexikon/techniklexikon.html

- ↑ Husni Taher Izweik Distation CFD INVESTIGATIONS OF MIXTURE FORMATION, FLOW AND COMBUSTION FOR MULTI-FUEL ROTARY ENGINE page 16

- ↑ 17. R. Kamo, RM Kakwani, and W. Hady, Adiabatic Wankel Type Rotary Engine, SAE Paper 860616 (1986).

- ↑ SAE Paper 2844263 Research and Development of a Direct Injection Stratified Charge Rotary Engine

- ^ Robert Bosch GmbH: Kraftfahrtechnisches Taschenbuch. 19th edition. 1984, ISBN 3-18-418005-0 , p. 329. 300-380 g / kWh

- ^ Bosch: Kraftfahrtechnisches Taschenbuch. 26th edition, 2007. ISBN 978-3-8348-0138-8 , p. 509. 380-500 g / kWh

- ↑ Wolf-Dieter Bensinger: Rotary piston combustion engines . Springer-Verlag, Berlin / Heidelberg, ISBN 3-540-05886-9 , pp. 84–85 ( “The mixture in the narrow gussets at the corners is hardly used; it has cooled down too much due to the unfavorable surface-volume ratio here. The combustion process is therefore slow, which on the one hand results in a poorer thermal efficiency, on the other hand very The result is pleasant, soft combustion (...) The rotary engine is undoubtedly inferior to the reciprocating piston engine in terms of thermodynamics, as the shape of the combustion chamber and the large heat-dissipating surfaces immediately reveal. " ).

- ↑ MTZ 10/2002 Volume 63 Fig. 4 page 812 The side outlet in the Renesis prevents unburned hydrocarbons from escaping from the combustion chamber into the outlet openings

- ↑ Wolf-Dieter Bensinger: Rotary piston combustion engines . Springer-Verlag, Berlin / Heidelberg 1973, ISBN 3-540-05886-9 , pp. 86–87 ( “Due to the slow combustion and the exhaust gas component present at part load, the nitrogen oxide emissions (NOx) in the Wankel engine are significantly lower than in the reciprocating engine (only approx. 40%) (...) are very much worse than in the reciprocating engine due to the unfavorable Combustion chamber shape, the hydrocarbon emissions (HC) (…) With regard to carbon monoxide (CO), reciprocating piston and rotary engines behave roughly the same. " ).

- ^ Another report from the Frankfurt IAA. In: Automotive Technology . 11/1963, pp. 421-423.

- ^ The ancestry of freedom motors. (PDF) (No longer available online.) Archived from the original on October 16, 2006 ; Retrieved October 9, 2008 (English, Freedom Motors family tree). Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ The incredible shrinking engine. (PDF; 1.1 MB) (No longer available online.) In: Forefront. University of Berkeley, 2001, archived from the original on July 10, 2010 ; accessed on October 9, 2008 (English, Der Berkley MEMS Wankel). Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Peter Münder: The rotary piston rotates again. In: The time. December 27, 2013, accessed December 27, 2008 .

- ↑ Berny Herrera: Rotapower Engine Achieves SULEV Emissions Goal. (No longer available online.) In: RotaryNews.com. August 10, 2006, archived from the original on December 21, 2008 ; accessed on October 9, 2008 (English). Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ March 25, 2009 first Premacy Hydrogen RE Hybrid leased and approved in Japan. Source Mazda Media

- ↑ Audi A1 e-tron ( Memento of the original from April 13, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. .

- ↑ The pocket-sized engine. September 1, 2016, accessed September 6, 2016 .

- ↑ Range Extender: Mazda wavers in the electromobility report of the IT-related news portal Golem.de from October 3, 2018, accessed on October 4, 2018

- ↑ PDF Mazda press release Electric vehicle with optional rotary piston engine range extender

- ↑ Stefan Zima, Reinhold Ficht: Unusual engines. 3rd edition, Vogel-Buchverlag, Würzburg 2010, ISBN 978-3-8343-3140-3 , p. 420.

- ↑ a b Road Test, Volume 9, Quinn Publications, 1973, p. 11

- ^ John B. Hege: The Wankel Rotary Engine: A History , McFarland, 2017, ISBN 978-0-7864-8658-8 , p. 102

- ↑ The world of August 25, 2000: Legendary rotary engine is waiting for a new chance

- ↑ Gmünder Tagespost from August 5, 2004: Mario Häberer is not fickle ( Memento of the original from July 14, 2015 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. .

- ↑ Motorcycle: Interview with Mario Häberer, Managing Director of Wankel AG: What about the Wankel MZ? ( Memento of the original from July 14, 2015 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. .

- ↑ Mazda Parkway Rotary 26 (1974) [1]

- ↑ Škoda MB Wankel jezdila a měla řadu výhod. Proč revoluční novinku v AZNP zamítli? -. In: autoroad.cz. February 19, 2018, accessed June 8, 2018 .

- ↑ Klaus Taubert : A status symbol is 50 - the "Wartburg" legend. In: klaustaubert.wordpress.com. January 23, 2017, accessed June 8, 2018 .

- ↑ Ben Hsu: History Lesson: Datsun's Own Rotary Engine, the 1972 Sunny RE. In: japanesenostalgiccar.com. November 30, 2012, accessed June 8, 2018 .

- ^ Erich Moechel: drone metropolis Wiener Neustadt. In: fm4.orf.at, March 15, 2012

- ^ Hydrogen and the Rotary Engine. (No longer available online.) In: MAZDA. Archived from the original on October 15, 2008 ; accessed on October 9, 2008 (English, Mazda hydrogen rotary engines). Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ The development network of e-volo ( Memento of the original from November 30, 2013 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. at e-volo.com; Retrieved November 23, 2013.

- ↑ Tom Grünweg: In the turning circle of the piston. at spiegel.de (visited on March 1, 2009).