Milling

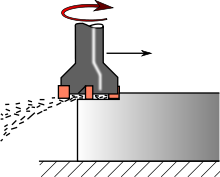

The milling is a metal-cutting production methods for the production of workpieces with a geometrically defined shape. As with all machining processes, material is removed from a blank in the form of chips . Milling belongs to the group machining with geometrically defined cutting edges , since the geometry of the cutting edges on the milling tools is known. During milling, the material is removed by the milling tool rotating around its own axis at high speed, while either the tool follows the contour to be produced or the workpiece is moved accordingly. During milling, this feed movement takes place perpendicular or at an angle to the rotation axis of the tool - when drilling, however, it takes place in the direction of the rotation axis and when turning , the workpieces rotate around their own axis while the tool follows the contour.

Milling is used in particular to produce flat surfaces. These include grooves or guides for moving machine parts . Before 1840, such shapes were mainly made by planing , after which it was quickly replaced by the much faster milling. However, complex three-dimensional shapes such as turbine blades or dies can also be produced on modern milling machines . A large part of all gears is manufactured by hobbing , for which special hobs are required. Threads are also possible. Special processes are hard milling and high-speed milling as variants of hard cutting and high-speed cutting .

Milling has a number of special features compared to other machining processes. On the one hand, it was only created in the 19th century together with the milling machines, while almost all other processes have been known since ancient times. In addition, it can only be done by machine, while there is almost always a manual variant. When milling, the individual cutting edges do not have constant contact with the workpiece. During one revolution, they penetrate the material, remove chips and detach themselves from the workpiece. This characteristic is referred to in the specialist literature as an interrupted cut . This leads to a jerky, fluctuating course of the cutting force that acts on the tool. The chip thickness changes during rotation and is not constant as in most processes. In addition, the angle between the cutting movement and the feed movement, the so-called feed direction angle, changes continuously during a tool revolution , which makes the calculation somewhat more complex. On the other hand, the cutting edges can cool down while they are not in contact with the workpiece and thus do not heat up as much. In addition, the interrupted cut creates short comma-shaped chips that cannot get caught in the machine. Separate measures for chip breaking are therefore not required.

definition

Milling is often defined as a machining production process in which the tool rotates. This is to be understood primarily as a demarcation from turning, another important manufacturing process in which the workpieces rotate around their own axis. Milling is defined as follows in DIN 8589, which is important for the classification and definition of machining processes and is often cited in the specialist literature:

Milling is machining with a circular, the tool associated cutting movement and any feed motion . The axis of rotation of the cutting movement maintains its position in relation to the tool regardless of the feed movement.

history

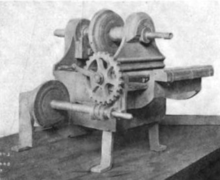

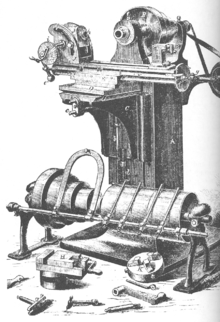

The oldest milling tool is said to be Jacques de Vaucanson and is said to date from 1760. The oldest recorded milling machine, on the other hand, dates from 1818 and was built by Eli Whitney , an American engineer. Milling was mainly used in the manufacture of firearms, for the production of grooves. While most machine tools, such as the lathe and planer , originated in England during the Industrial Revolution , the milling machine and milling machine was primarily an American development. There it was continuously improved in the period that followed. However, it also spread across Europe. The famous British machine tool builder James Nasmyth built one around 1830.

Machine tools were improved by two technical innovations from the early 20th century, the electric motor and the electric controls . The latter made it easier to operate, as numerous functions could be automated. In addition, it made copy milling possible, with which workpieces with complex shapes could also be produced economically in medium quantities. However, the prerequisite was the use of electric motors as a drive.

Classification

Differentiation according to the direction of travel

When milling, it is important to note how the direction of tool rotation relates to the direction of feed when cutting the tool cutting edge in the workpiece. Since the width of the incision should normally be no more than 2/3 of the tool diameter, the direction of travel is clear.

Up-cut milling

With up-cut milling, the cutting edge of the rotating tool moves in the area of engagement against the feed direction of the workpiece and forms a chip that thickens from the entry point to the exit point of the cutting edge (comma chip). Before the cutting edge enters the material, it slides on the work surface and solidifies the existing structure. This first creates high friction and then the cutting edge has to penetrate the solidified material. As a result of the increasing chip thickness, the machine is loaded differently and tends to vibrate (see also: Regenerative Effect ). The effort required is also slowly increasing as a result. When entering the cutting edge, it is low because little material has to be removed, but then increases during the milling process and reaches its maximum value shortly before the cutting edge exits, before the comma chip is finally cut off.

The high pressure generated by the compression during the milling process causes severe wear to the flanks on the cutting edges, which reduces the service life . Due to this disadvantage, up-cut milling only makes economic sense when workpieces have hard ( cast skin or scale ) and wear-resistant edge zones (less hardening effect) or when the table drive is not without play. The surfaces milled in the opposite direction have a smooth but wavy structure due to the sliding action of the cutting edge.

For table drives with backlash, which usually only occurs in older or defective milling or boring mills, up-cut milling is recommended, because with this the milling cutter presses the driven workpiece table with evenly distributed load against the drive spindle. In this way, there is no play for the feed and undesired slide movements are excluded.

Climb milling

With down-cut milling, the cutting edge of the rotating tool moves in the area of engagement in the direction of the vector of the workpiece feed direction . If the force builds up slowly with up-cut milling, with down-cut milling it is greatest immediately at the cutting edge, but then decreases continuously. The chip becomes thinner and thinner towards the cutting edge and finally peeled off, which results in a smoother surface compared to up-cut milling (here too the chip is comma-shaped, but in this case a lot of material is removed at the beginning and little at the end).

The tendency of the milling cutter, due to the direction of force, to jerk the workpiece in the feed direction, favors unwanted changes in the slide or workpiece position. Therefore, the feed device of the slide of the machine tool must have absolutely no backlash or high rigidity, for which ball screw drives are suitable. Due to the lower tendency to chatter, the surface qualities that can be achieved with down-cut milling are better than up-cut milling under otherwise identical cutting conditions - provided that these do not favor the formation of built- up edges .

Because of the lower cutting edge and flank wear, the feed rate can be increased by 50% compared to upstream milling with the same tool life .

Classification of milling processes according to DIN 8589

The classification of milling, which is often cited in the specialist literature, is carried out, as in all other machining processes, according to the shape produced into face, round, screw, hob, profile and form milling. Face and profile milling is further subdivided according to the surface on the tool that creates the shape, milling into face, circumference and face circumference (profile). In the reform of DIN 8589 in September 2003, all procedures were given a serial number. In milling, all processes begin with sequence 3.2.3 (3rd main group: cutting , 2nd group: cutting with a geometrically defined cutting edge , 3rd manufacturing process: milling).

Face milling

Face milling is used to produce flat surfaces. These include shoulders, sealing surfaces on flanges , motor or gear housings , guideways on machine tools , turret faces, basic tool holders and three- jaw chuck faces. Face milling bears the order number 3.2.3.1. Face milling is the most frequently used variant. In practice, the further subdivision is usually made according to the tools used in cylindrical milling , end milling , disc milling and others.

- 3.2.3.1.1 With circumferential face milling, the newly created surface is created with the cutting edges that are attached to the circumference of the milling cutter. The axis of the milling cutter is parallel to the surface created.

- 3.2.3.1.2 With face milling , the newly created surface is created with the cutting edges on the face. The cutter axis is perpendicular to the surface created. The main cutting work is still done by the main cutting edges on the circumference, only the surface is created by the secondary cutting edges on the face, which is therefore of high quality. When face milling, the engagement width is usually significantly larger than the cutting depth . If the tool entering angle is also known as shoulder milling . Generally it takes values between 45 ° and 75 °.

- 3.2.3.1.3 With face milling , both the cutting edges on the circumference and those on the face are used to create two new surfaces.

Round milling

Circular cylindrical outer or inner surfaces are created with circular milling. The likewise circular feed movement can be generated by the tool or the workpiece. Round milling bears the order number 3.2.3.2.

- 3.2.3.2.1 Circumferential milling is characterized by the fact that the tool axis is parallel to the axis of rotation of the cylinder produced. This variant is also known as orbital milling or circular milling and is used to manufacture bores . It has the advantage over drilling that the diameter of the hole is not included in the tool. Different diameters can be produced with one milling tool. However, this requires a complex CNC control .

- 3.2.3.2.2 With face milling , the tool axis is perpendicular to the axis of the generated cylinder. It is also known as turn-mill.

- 3.2.3.2.3 With face circumferential milling , the tool axis can be perpendicular or parallel to the generated cylinder. There are cutting edges on the circumference and on the face in engagement. This variant is also referred to as turning-milling.

Screw milling

Screw milling with the serial number 3.2.3.3 is used to produce screw-type shapes, including in particular threads , spindles or cylindrical worms .

- 3.2.3.3.1 With long thread screw milling , a single-profile thread milling cutter is used. The feed corresponds to that of the thread pitch. The tool axis is slightly inclined in relation to the thread. It is similar to threading .

- 3.2.3.3.2 Short thread screw milling uses a multi-profile tool that is not inclined with respect to the thread. Here, too, the feed corresponds to that of the thread pitch. However, it only takes a little more than one workpiece rotation to produce the thread. It is similar to thread chasing .

Hobbing

The hobbing with the order number 3.2.3.4 is used to generate rolling surfaces . These include, above all, gears on gears and racks . In principle, these can also be produced by gear planing and gear shaping or drop forging , but gear hobbing is the most important process. The hob cutters used have a profile that corresponds to that of the teeth to be produced. The rotation of the milling cutter, the feed and the rotation of the gear to be produced are coordinated with one another. The gears are then usually finished by generating grinding.

Profile milling

The profile milling with the order number 3.2.3.5 uses profile cutter in which the manufactured form is included as a negative, to produce profiles. These include T-slots, dovetail slots or the chip slots on large milling cutters. Circumferential grooves can also be created for workpieces that rotate around their own axis. Depending on the feed movement, round, straight or any shapes can be created. Numerous form elements on workpieces such as radii and bevels are standardized. Therefore there are also corresponding standardized profile milling cutters.

- 3.2.3.5.1 Longitudinal profile milling is carried out with a straight feed movement.

- 3.2.3.5.2 Round profile milling, on the other hand, with a circular feed movement.

- 3.2.3.5.3 Form profile milling is carried out with any feed movement.

- 3.2.3.5.4 is profile milling with a milling chain .

Form milling

In form milling, tools are used that do not contain the shape to be generated. Any three-dimensional shapes can be created by controlling the feed movement. Form milling has the serial number 3.2.3.6 and is classified according to the type of control.

- 3.2.3.6.1 With free-form milling , the movement is controlled manually.

- 3.2.3.6.2 When Nachformfräsen a used template or a masterpiece as a template. Their shape is scanned and passed on to the feed drives of the machine. The variant is also known as copy milling and has hardly been used since the introduction of CNC controls.

- 3.2.3.6.3 With kinematic profile milling , gears are used to generate movements. These include cams or drum cams . It was used to manufacture large series of identical workpieces, but is rarely used today.

- 3.2.3.6.4 The NC mold milling uses a numerical control (English: numerical control), now mostly in the form of a CNC (computerized numerical control). In addition to the three movements in each axis direction, the tools can also be swiveled around two axes in order to create complex shapes. (The third axis is the rotation axis of the tool and therefore does not change the shape produced.) This process is used for the production of dies in mold making , for the production of casting molds ( direct molding material milling ) or for turbine blades .

Distinctions according to the materials to be processed

Wood is milled without cooling lubricant (KSS) and at a high cutting speed. Since wood is a poor conductor of heat, high temperatures occur on the tool surfaces. Therefore, the feed rate and milling depth must be selected so that the surface does not show any scorch marks. Plastics are machined at very high cutting speeds (200–3000 m / min). Depending on the type of material (hardness and plastic behavior), water, alcohol, air or oil is used for cooling.

The cutting speed for metals covers a wide range depending on the type (brittle or tough). Machines such as those found in workshops or training facilities are used at cutting speeds of around 15–500 m / min. In series production or with milling-intensive workpieces, for example in Pelton turbines , all parameters are optimally matched to one another due to the economic efficiency, and speeds of up to 10,000 m / min are possible. In most cases, cooling lubricants are used, but there is a clear tendency towards dry machining and minimum quantity lubrication . The share of coolant costs in the total costs of a milled workpiece is between 10 and 20%.

The tools used also differ greatly in terms of cutting material and shape. In contrast to metal cutters, wood and plastic cutters always have a positive rake angle and larger chip spaces . In practice, single or double-edged end mills are used for machining plastics.

Distribution of forces

Each cutting edge of the milling tool exerts the cutting force F tot on the workpiece . It is composed of the main cutting force F c (cutting force) in the direction of the cutting movement (i.e. tangential), the normal cutting force F cN in the direction normal to the cutting movement and the passive force F p in the direction of the tool's axis of rotation. The cutting force F tot is the vector sum of the forces F c , F cN and F p .

See also

- List of machining processes

- Chip formation

- Machinability

- High speed machining

- Energy conversion and heat during machining

swell

- ↑ Fritz Klocke , Wilfried König: Production Process Volume 1: Turning, Milling, Drilling , Springer, 8th edition, 2008, p. 23 f.

- ^ Günter Spur: On the change in the industrial world through machine tools , Carl Hanser Verlag, Munich, Vienna, 1991, p. 344.

- ^ Ulrich Fischer (Ed.): Fachkunde Metall , 53rd edition 1999. Verlag Europa-Lehrmittel, p. 169

- ↑ Gerald Frömmer and Armin Steinmüller (ed.): Zerspantechnik shedding , Verlag Europa-Lehrmittel, 2000, p 118

- ↑ Dirk Kammermeier: Overview of the milling processes in: Uwe Heisel, Fritz Klocke, Eckart Uhlmann, Günter Spur (eds.): Handbuch Spanen. 2nd edition, Hanser, Munich 2014, pp. 401–403.

- ↑ Dirk Kammermeier: Overview of the milling processes in: Uwe Heisel, Fritz Klocke, Eckart Uhlmann, Günter Spur (eds.): Handbuch Spanen. 2nd edition, Hanser, Munich 2014, p. 402.

- ↑ Herbert Schönherr: Machining , Oldenbourg, 2002, p. 228.

- ↑ Fritz Klocke, Wilfried König: Production Process Volume 1: Turning, Milling, Drilling , Springer, 8th Edition, 2008, p. 430.

- ↑ Dirk Kammermeier: Overview of the milling processes in: Uwe Heisel, Fritz Klocke, Eckart Uhlmann, Günter Spur (eds.): Handbuch Spanen. 2nd edition, Hanser, Munich 2014, p. 402.

- ↑ Herbert Schönherr: Machining , Oldenbourg, 2002, p. 229.

- ↑ Dirk Kammermeier: Overview of the milling processes in: Uwe Heisel, Fritz Klocke, Eckart Uhlmann, Günter Spur (eds.): Handbuch Spanen. 2nd edition, Hanser, Munich 2014, p. 402.

- ↑ Heinz Tschätsch: Practice of machining technology. Process, tools, calculation. 11th edition, Springer Vieweg, Wiesbaden 2014, p. 157.

- ↑ Fritz Klocke, Wilfried König: Manufacturing Process Volume 1: Turning, Milling, Drilling , Springer, 8th edition, 2008, p. 430 f.

- ↑ Fritz Klocke, Wilfried König: Manufacturing Process Volume 1: Turning, Milling, Drilling , Springer, 8th Edition, 2008, p. 433.

- ↑ Dirk Kammermeier: Overview of the milling processes in: Uwe Heisel, Fritz Klocke, Eckart Uhlmann, Günter Spur (eds.): Handbuch Spanen. 2nd edition, Hanser, Munich 2014, p. 402.

- ↑ Herbert Schönherr: Machining , Oldenbourg, 2002, p. 229

- ↑ Alfred Herbert Fritz, Günter Schulze (ed.): Manufacturing technology , Springer, 11th edition, 2015, p. 323 f.

- ↑ Herbert Schönherr: Machining , Oldenbourg, 2002, p. 229 f.

- ↑ Herbert Schönherr: Machining , Oldenbourg, 2002, p. 229 f.

- ↑ Herbert Schönherr: Machining , Oldenbourg, 2002, p. 229 f.

- ↑ Herbert Schönherr: Machining Technology , Oldenbourg, 2002, p 230th

- ^ Alfred Herbert Fritz, Günter Schulze (Ed.): Manufacturing technology. 11th edition. Springer Vieweg, Berlin / Heidelberg 2015, p. 324.

- ↑ Herbert Schönherr: Machining Technology , Oldenbourg, 2002, p 230th

- ^ Alfred Herbert Fritz, Günter Schulze (Ed.): Manufacturing technology. 11th edition. Springer Vieweg, Berlin / Heidelberg 2015, p. 324.

- ↑ Alfred Herbert Fritz, Günter Schulze (Ed.): Fertigungstechnik , Springer, 9th edition, 2010, p. 302.

- ↑ Herbert Schönherr: Machining , Oldenbourg, 2002, p. 230 f.

- ↑ Herbert Schönherr: Machining , Oldenbourg, 2002, p. 231.

- ↑ Alfred Herbert Fritz, Günter Schulze (Ed.): Fertigungstechnik , Springer, 9th edition, 2010, p. 302.

- ↑ Uwe Heisel, Fritz Klocke, Eckart Uhlmann, Günter Spur (eds.): Handbuch Spanen. 2nd edition, Hanser, Munich 2014, p. 402.

- ↑ Uwe Heisel, Fritz Klocke, Eckart Uhlmann, Günter Spur (eds.): Handbuch Spanen. 2nd edition, Hanser, Munich 2014, p. 402.

- ↑ Herbert Schönherr: Machining Technology , Oldenbourg, 2002, p 231 f.

literature

- Jürgen Eichardt: Milling for model makers. Volume 1 and 2, Verlag VTH, 2002, ISBN 3-88180-717-9 and ISBN 3-88180-718-7

- Jürgen Eichardt: Milling with a lathe. Verlag VTH, 2nd edition 2002, ISBN 3-88180-099-9