crankshaft

A crankshaft is a special shaft with integrated cranks and is used in particular in piston engines. It converts the reciprocating movement of one or more pistons into a rotary movement with the help of connecting rods (or vice versa). The components required for converting one type of movement into the other make up the crank mechanism .

The crankshaft is mounted in the crankcase . The component sequence cheek - crank pin - cheek is referred to as the crankshaft offset .

history

The first known machine in which a rotary motion was converted into a linear motion with the help of a crankshaft and connecting rod is the Roman sawmill of Hierapolis (3rd century).

The Dutch inventor Cornelis Corneliszoon used a crankshaft to run a sawmill through a windmill. In 1597 he received a patent for his crankshaft.

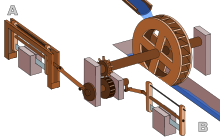

In the Reiffenstuel piston pressure pump , the power was transmitted from an overshot waterwheel to three pistons via a crankshaft. This pump was developed by Simon Reiffenstuel in 1612 for the "first pipeline in the world", the brine line from Reichenhall to Traunstein .

function

The crankshaft has the task of absorbing the piston forces that are conducted via the connecting rod, converting them into torque and transmitting this to the transmission via the clutch .

Crankshafts can also be stored in a height-adjustable manner, which enables variable compression. The crankshaft is raised by an eccentrically mounted crankshaft bearing. The advantage of variable compression is that consumption is up to 25% lower in the partial load range.

In order to be able to conduct engine oil within the one-piece crankshaft to the main and connecting rod bearings for lubrication purposes , the crankshaft is hollow bored , the oil is fed through a main bearing and then exits through bores in the shaft and crankpin. When the shafts are assembled, the main and connecting rod bearings are not plain bearings , but rather roller bearings ; these do not require pressure oil lubrication , but are supplied with lubricant by the oil mist in the cylinder crankcase .

Set

In the case of an offset crankshaft drive in a reciprocating piston engine , the crankshaft is offset laterally with respect to the cylinder axis. When the piston is at top dead center (TDC), the central axis of the connecting rod is no longer in the parallel plane of the cylinder axis.

The set can be used for various purposes:

- An offset on the counter-pressure side causes the piston to tilt earlier and the contact surface on the cylinder wall changes. In the case of a crankshaft drive without skew, this happens after TDC when there is already a high combustion pressure on the piston, so that tilting (changing the contact side) leads to increased noise (NVH, Noise Vibration Harshness ).

- An offset to the pressure side can reduce the friction, since the piston side force decreases and with it the friction between the piston skirt and the cylinder wall. This is particularly advantageous in the case of frequent full-load operation (for example in construction machinery).

- In VR engines , the offset is alternately carried out on the pressure or counter-pressure side, which is due to the geometry (penetration of the cylinder). This means that the cylinder axes are "more parallel". Without this offset pattern, the cylinder liners would penetrate too much and the pistons could touch or not make the full stroke.

The offset is often supplemented by offsetting the piston pin .

Examples of implemented engines:

- 12 mm to the counter pressure side of the Mercedes-Benz OM 654 ,

- 7 mm to the pressure side of the non-road engine family from FEV ,

- 14 mm for the 1.0 l 3 cylinder turbo engine from Honda (direction of offset not specified),

- 12.5 mm for the VW W12 TSI in the two blocks of the engine and also for the VR 5.

The restriction also requires adjustments to the tax times.

construction

A crankshaft consists of the following elements:

- Shaft journal. These run in the base bearings ( main bearings ) and define the axis of rotation of the shaft .

- Connecting rod bearings on which the push rods ( connecting rods ) are mounted. During operation, they describe a circular path around the axis of rotation of the crankshaft. The diameter of this circular path corresponds exactly to the piston stroke of the piston.

- Crank webs that connect the connecting rod bearings to the shaft journals.

- Counterweights that are attached to the cheeks are usually used for balancing (e.g. in- line engines ).

The rotating mass forces are completely and the oscillating first order mass forces are usually balanced to 50% by attaching counter masses. However, this has the effect of increasing the weight of the crankshaft. A further reduction in oscillating inertial forces of the first and second order does not take place via measures on the crankshaft, but via the Lanchester compensation .

Types and production

A distinction is made between built crankshafts composed of individual parts and forged or cast crankshafts made in one piece.

Cast crankshaft ( sand casting ) made of cast iron .

Forged crankshaft ( drop forging ) made of steel. The back two after forging, then after trimming, front after grinding

built crankshaft made of stainless steel

literature

- Ritti, Tullia; Grewe, Klaus; Kessener, Paul: A Relief of a Water-powered Stone Saw Mill on a Sarcophagus at Hierapolis and its Implications. In: Journal of Roman Archeology , Vol. 20: 2007, pp. 138-163

- Wilfried Staudt: Handbook Vehicle Technology Volume 2. 1st edition, Bildungsverlag EINS, Troisdorf, 2005, ISBN 3-427-04522-6

- Jan Drummans: The car and its technology. 1st edition, Motorbuchverlag, Stuttgart, 1992, ISBN 3-613-01288-X

Web links

- ws-technik.info: The crank drive ( Memento from August 1, 2016 in the Internet Archive )

- Image display for "twisting"

Individual evidence

- ↑ Ritti, Grewe, Kessener (2007), p. 161

- ↑ www.fev.com, Advanced Concepts , accessed November 17, 2010

- ↑ Richard van Basshuysen, Fred Schäfer (Ed.), " Handbuch Internal Combustion Engine ", Section " 6.1.1 Structure and Function ", 8th edition 2017, Springer Fachmedien Wiesbaden GmbH, ISBN 978-3-658-10901-1

- ↑ Günter P. Merker, Rüdiger Teichmann (Ed.), " Basics of Combustion Engines ", Springer Fachmedien Wiesbaden, 7th edition 2014, section " 19.3.1 Alternative Concepts ", ISBN 978-3-658-03194-7

- ^ A b Thomas Hamm, Michael Neitz, Vinod Rajamani, Sven Lauer: Nonroad engine family for emerging markets . In: ATZ offhighway . Springer Fachmedien, March 1, 2016, ISSN 2191-1843 .

- ↑ J. Liebl (Ed.): Mercedes-Benz E-Class . ATZ / MTZ type book. Springer Fachmedien, Wiesbaden 2017, ISBN 978-3-658-18443-8 .

- ↑ Tomonori Niizato, Mitsuhiro Shibata, Michael Fischer, Ulf Reinschmidt: The new 1.0-l three-cylinder gasoline engine from Honda . In: MTZ Motortechnische Zeitschrift . Springer Vieweg, Springer Fachmedien, January 1, 2018, ISSN 0024-8525 , Table 1 Technical data .

- ^ Friedrich Eichler, Wolfgang Demmelbauer-Ebner, Jürgen Strobel, Jens Kühlmeyer: The new W12 TSI engine of the Volkswagen Group . In: MTZ Motortechnische Zeitschrift . Springer Vieweg / Springer Fachmedien, February 1, 2016, ISSN 0024-8525 , Table 1 Technical data of the W12 TSI .

- ↑ Bern Ebel, Uwe Kirsch, Frank Thomas Metzner: The new five-cylinder engine from Volkswagen . In: MTZ Motortechnische Zeitschrift . Springer Vieweg / Springer Fachmedien, January 1, 1999, ISSN 0024-8525 , Table 1 Technical data .