Fuel pump

A fuel pump is used to transport the fuel in the required quantity and with the necessary pressure from the fuel tank to the carburetors , injection valves or injection pumps of internal combustion engines or jet engines , provided these are not supplied by a fall gasoline system.

construction

Apart from conventional diesel systems and some of the diesel common rail systems of the "first" generation, which still work with displacement pumps mechanically driven by the combustion engine, today's fuel pumps are electrically driven and are located in or near the fuel tank. The electric drive is deliberately not separated from the fuel, but rather flows through it. This ensures optimal cooling and lubrication of the electric fuel pump. There is no risk of fire due to flying sparks or overheating because air (and thus the oxygen required for combustion) is displaced by the fuel in the relevant parts.

Types and funding

Depending on the intended use, the delivery capacities of fuel pumps range from small quantities in vehicle engines to enormous capacities in rocket engines.

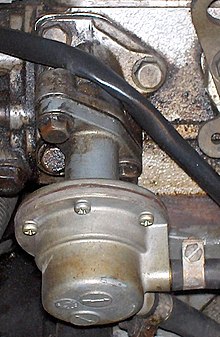

With carburetor engines, the tank of which can be on the same or lower level than the level of the float chamber, self-regulating diaphragm pumps with delivery pressures between 0.15 and 0.40 bar are used as a rule.

For injection engines, higher pressures are required, especially if the fuel pump has to provide the necessary pressure for an intake manifold injection . Flow pumps (peripheral or side channel principle) are mainly used for the main or preliminary delivery of gasoline, displacement pumps (gerotor, gear or roller cell principle) for the preliminary delivery of lubricious diesel oil. The delivery rate depends heavily on the combustion engine to be supplied and the tank components (e.g. suction jet pumps in saddle tanks) and is usually between 80 and 250 l / h at an operating pressure of 3 to 7 bar. Only about a tenth of the flow rate is used in the injection engine, the excess fuel flows back into the tank via the return line. The power consumption of a pump for tuning and motorsport is between 9 and 13 A with a 12 volt on-board voltage, the power consumption of over 100 watts corresponds to less than a thousandth of the possible engine power.

In top fuel class dragster engines, around half a liter of nitromethane per second (8 GPM, US gallons per minute) is pumped into a cylinder.

Each of the five F-1 engines of the Saturn V moon rockets requires more than two tons of liquid propellant per second, which are pumped with a 40 megawatt turbo centrifugal pump for cooling around the combustion chamber and for combustion in it. In the Russian RD-170 engine, four combustion chambers are bundled, which are supplied by a turbo pump with an output of 190 MW.

reliability

Since failure of the fuel pump inevitably brings the vehicle to a standstill, an extremely high level of reliability is required, with a failure-free operating time of 5000 to 10000 hours. This represents a considerable challenge, especially for alternative petrol based on ethanol or methanol, but also for all diesel fuels (here again especially for so-called biodiesel based on RME). Although an electric motor with electronic commutation ( brushless motor ) is the ideal solution, it was The classic commutator motor (brush motor) has been further developed for cost reasons . The development goal was achieved by switching to a commutator made of graphite instead of copper.

literature

- Max Bohner, Richard Fischer, Rolf Gscheidle: Expertise in automotive technology. 27th edition, Verlag Europa-Lehrmittel, Haan-Gruiten, 2001, ISBN 3-8085-2067-1

- Hans Jörg Leyhausen: The master craftsman's examination in the automotive trade part 1. 12 edition, Vogel Buchverlag, Würzburg, 1991, ISBN 3-8023-0857-3

See also

Web links

Individual evidence

- ↑ Bosch Motorsport Fuel Pump FP 200 5 bar No. 0 580 254 044 bosch-motorsport.de

- ↑ pumps comparative test realstreetperformance.com

- ↑ Video with the glass cylinder demonstration pump at the Wally Parks NHRA Motorsports Museum in Pomona, CA topspeed.com

- ↑ Pump with up to 116 GPM (439 liters / min, 7 liters / sec) watermanracing.com