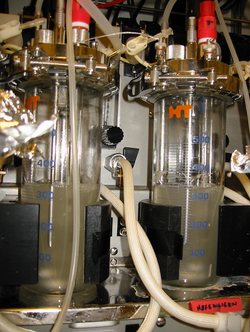

Chemostat bioreactor

The chemostat -Culture is a common method of cultivation of microorganisms . In contrast to batch culture (static culture), it is a form of continuous culture of, for example, bacteria or phytoplankton .

A chemostat is a culture vessel into which nutrient medium is fed continuously and at a constant rate ( flow rate ) . At the same rate as fresh nutrient medium is supplied, the used medium including the organisms suspended in it is removed via an overflow. This simulates the mortality rate of natural populations . Is the flow rate in the chemostat less than the maximum growth rate of the cultured organisms, then provides a steady state ( steady-state a), wherein the gross growth rate of the loss rate corresponds. The number of organisms per volume thus remains constant and, should fluctuations occur, it is self-regulating. If the population density decreases, fewer nutrients are consumed, that is, the nutrient concentration increases. This in turn results in an increase in the number of individuals, which in turn leads to a reduction in the amount of nutrients per volume, etc.

Using the chemostat culture, parameters of the population development can be investigated as models.

Determination of the optimal dilution rate

In order to be able to determine the optimal dilution rate, the parameters must be determined in such a way that the production rate is maximized. The production rate is the product of the inverse residence time or dilution rate (dilution rate) D [h −1 ] (nominal exchange frequency for the reactor volume, quotient of volume inflow / outflow and liquid reactor volume) and the biomass concentration x [typically g biomass L −1 ]. Since the concentration of biomass is to remain constant in the reactor is considered for the growth rate: μ = D .

The following applies to the maximum production rate:

The production rate reaches its theoretical maximum close to the critical dilution rate D crit. From which the growth rate is smaller than the dilution rate and therefore the biomass in the reactor decreases. The chemostat's maximum productive dilution rate for exponential growth is given by:

S with a substrate concentration in the inlet and K s the Monod constant. D opt is close to the critical dilution rate D crit . Since from this point on, the biomass is flushed out faster than it is formed, a chemostat is typically not operated at this potentially unstable operating point.

Individual evidence

- Journal Article Proc. NAS 1950 , 36 , pp. 708-719. doi: 10.1073 / pnas.36.12.708

- ^ Horst Chmiel, 2006, Bioprozesstechnik 2nd edition, Elsevier Spektrum Akademischer Verlag, ISBN 3-8274-1607-8