Steam jet feed pump

Steam jet feed pumps are equipped with steam -driven jet pumps , as the feed pumps for steam generator of the steam power plants and steam locomotives are used.

Alexander Friedmann (1838–1882) developed it from Giffard's injector in 1868 , manufactured it in Vienna and successfully sold it, a. a. because the carefully experimented pump, which was simple and had no moving parts, worked very reliably. It was known as the Friedmann injector . Ernst Körting developed the pump further (including higher water temperature possible, easier production) and acquired a patent. Messrs. Körting Hannover AG manufactures jet pumps today.

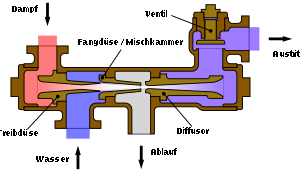

principle

The high pressure steam extracted from the boiler is fed into a pipeline with a nozzle , where it reaches a high exit speed. Supply water is sucked in from a bypass pipe and accelerated to the speed of steam. The speed of the water is converted into static pressure by braking in the opposite diffuser , which is higher than the overpressure in the boiler. The water is thus transported into the boiler. This process is only possible because the hot steam is cooled and condensed by the feed water. When decelerating, the water reaches a higher pressure than steam could reach at the same speed, on the one hand because it has a higher density and on the other hand because, unlike steam, it is not compressible and thus does not convert the gained flow energy back into heat by compression can be.

Use with the steam locomotive

This type of feeding device, often also known as the “ injector ”, is divided into non-sucking and sucking pumps, depending on whether the water flows from the tender to the pump or has to be sucked in by it. The first-mentioned pumps (Friedmann type) have a somewhat simpler construction, but are exposed to the risk of freezing in steam locomotives, as they have to be lower than the tender floor and are therefore usually located below the driver's cab. The suction pumps have the advantage that they are more accessible. They are screwed to the side of the rear boiler and are therefore protected from frost.

The Friedmann exhaust steam injector is a special design for the locomotive steam jet pumps. Here part of the machine exhaust steam is used as motive steam for the injector. Live steam can also be added if the machine output is low and the amount of exhaust steam is insufficient. When the locomotive is at a standstill, the exhaust steam injector can also only be operated with live steam.

The steam jet pumps are characterized by their simple construction and very low wear and tear, as, unlike piston pumps, they have no moving parts. However, the water to be pumped must have a sufficiently low temperature for the pump to operate reliably.

literature

- W. Müller, W. ller: The ship engine . Salzwasser Verlag, Paderborn 2011, reprint of the original from 1908, ISBN 978-3-86444-015-1 .

- Max Wutz, Hermann Adam: Theory and Practice of Vacuum Technology. 4th edition, Vieweg Verlag, Braunschweig / Wiesbaden 1988, ISBN 3-528-24884-X .

- Konrad Hartmann, J. Oskar Knoke: The pumps. Second increased edition, Springer Verlag Berlin Heidelberg GmbH, Heidelberg 1897.

Web links

- Steam jet pump in Lexicon of Physics. (accessed on December 28, 2015)

- Lecture 6 - TU Ilmenau (PDF, accessed December 28, 2015)

Individual evidence

- ^ Anonymus: New Friedmann'scher Injector. In: Polytechnisches Journal . 232, 1879, pp. 501-502.