Wire race bearings

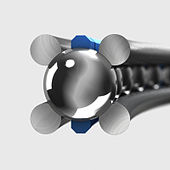

Wire race bearings are roller bearings whose rolling elements run on comparatively filigree running wires instead of being enclosed by a wider inner and outer ring. For stabilization, the running wires must be inserted into corresponding recesses or recesses in the surrounding structure. Balls or rollers, which are positioned by a cage, are usually used as rolling elements.

The wire race bearing was invented in 1934 by Erich Franke, co-founder of Franke und Heydrich KG, Aalen / Württ. (today Franke GmbH). As a young designer at the Carl-Zeiss-Werke in Jena, Franke tried to find a particularly space-saving storage with a large radius for an optical device. The storage had to be integrated into the surrounding construction in order to make it as compact and light as possible.

Types

As pure axial bearings or radial bearings , wire race bearings require at least one inner and one outer ring. For better guidance, bearing wires of ball bearings are given concave raceways. Variants with three or more rings are also used for special applications, e.g. B. to compensate for an angular misalignment of the inner and outer ring. They are also designed as angular contact ball bearings , angular contact roller bearings or three-row roller bearings , with the rolling elements rolling on one another in two or more rows.

Comparison with standard ball bearings

Wire race bearings are also space-saving, have a high load rating and can absorb forces from all directions.

Wire race bearings can, for example, also be inserted into the outer or inner toothed rims of gears .

With wire race bearings, the rotational resistance or the preload can be precisely adjusted using a corresponding device in the surrounding construction . The running wires can adapt to the load direction under load. In this way, especially with multi-row roller bearings, low and uniform rotational resistance can be achieved even when the adjacent construction and the surrounding rings are deformed. Hardenable, rust-proof materials can be used as materials for the running wires.

In addition to the higher construction effort, the assembly effort when inserting the races into the surrounding construction can also be viewed as disadvantageous. Special care is required to ensure that it functions properly. Ready-to-install wire roller bearings are preferably used, the running wires, rolling elements and cages of which are already mounted in the surrounding rings and the desired bearing function values such as B. preload and running accuracies are set.

Application examples of wire race bearings

Wire race bearings are used in particular when the installation space for storage is very tight or a lightweight construction is desired.

Web links

- Design practice specialist articles, rolling bearings

- Animated functional principle of wire race bearings

Individual evidence

- ↑ a b Decker / Kabus, machine elements, function, design and calculation, page 422, Hanser, 15th edition 2000, ISBN 3-446-21525-5

- ↑ Roloff / Matek, Hardware, Standards, Analysis, Design, page 486, Vieweg, 14th Edition 2001, ISBN 3-528-84028-5