Homokinetic joint

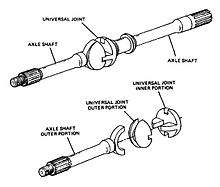

A constant velocity joint , also known as a constant velocity joint , is a joint for the uniform transmission of angular speed and torque from one shaft to a second shaft attached at an angle to it.

tasks

Constant velocity joints are used in mechanical engineering and on drive shafts in automotive engineering. Unlike simple universal joints , they transmit the rotary motion uniformly, which means that the angular speeds of the drive and output sides do not differ from one another. This avoids irregularities in the drive train and additional loads on the surrounding components. Constant velocity joints are most widespread in vehicle construction. There are many designs, for example in automobiles, if the flexion angle is the same on both sides and the inner forks and the flexion are in one plane (Z, W arrangement). The types listed below are a selection of the many constructions.

species

Wide-angle joints

Wide angle joints are typically required on front-wheel drive or all-wheel drive vehicles. They enable the deflection of the wheels required for steering axles and a bending angle of up to approx. 50 °.

- Homokinetic universal joint - a special version of the double universal joint

- Tracta joint - used by Tracta itself from 1927 and later under license from DKW, Adler and the supplier Bendix in the USA. It consists of forks on the shaft ends and two intermediate pieces that slide on them. During the Second World War it was found in all-wheel drive off-road vehicles, such as the jeep.

- Wide angle ball joint. In 1928 , engineer Alfred Hans Rzeppa , employed by the US manufacturer Ford , invented a constant velocity joint with balls running in a cage. It is characterized by a large deflection angle, relatively simple manufacture and a long service life. It is now installed in almost all front-wheel drive cars.

Sliding joints

With most wheel drives, the change in length of the drive shaft must be compensated for when the wheel is compressed. This type of joint is used on the transmission side in front-wheel drive vehicles and generally in rear-wheel drive vehicles. They enable angular deflections of up to around 20 ° and displacements of up to 30 mm.

- Tripod joint contains three cambered rollers between the inner and outer part .

- Constant velocity displacement joint with balls in a cage, similar to the Rzeppa joint. Patent of the Offenbach company Löhr und Bromkamp (LÖBRO - today part of GKN Driveline Germany ).

maintenance

Constant velocity joints must be lubricated by a grease pack, which is why they are usually encapsulated with an axle sleeve ( rubber or TPE material) to prevent contamination. This is usually made in one piece and is slipped over the shaft for assembly, which is why the shaft must be removed from the driven element (e.g. the front wheel of a vehicle) for this purpose.

literature

- Graf von Seherr-Thoss, Schmelz, Aucktor joints and cardan shafts. Calculation, design, applications Springer, 2002. ISBN 3540417591

Web links

- Image of the tract joint

- Ball joint on kfz-tech.de

- Tripod joint on kfz-tech.de

- Constant Velocity Joints (with a short text on the Rzeppa joint; English)