Rubber blanket

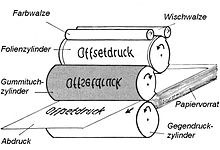

The rubber blanket ( English blanket rubber ) or blanket is a term used in the offset printing and refers to an intermediate support with which the printing ink from the printing plate to the printing is transferred. For this purpose, the rubber blanket is stretched onto a rubber blanket cylinder, or rubber cylinder for short , which is operated between the plate cylinder with the printing plate and the impression or impression cylinder with the printing material.

properties

A rubber blanket consists of several layers of rubber with layers of fabric in between. These fabric layers determine the tensile strength, whereby one kind of running direction has to be considered, because the fabric is largely stretch-resistant only in the direction of the so-called warp threads . With some blankets, this direction is indicated by colored threads on the back of the blanket. You have to walk around the cylinder. With other blankets, a gripper edge is printed on, which indicates the clamping direction. The top layer of rubber, the top layer, primarily determines the print quality. Their properties must not be impaired by washing with unsuitable detergents.

A distinction is made between compressible and incompressible rubber blankets. Compressible here means that the rubber blanket can be compressed without forming a bulge in the pressure zone. Compressible blankets are mainly used. Such an elastic rubber blanket has certain surface characteristics that the dampening water retains in non-printing parts and does not output to the paper. It is also able to compensate for any unevenness in the printing material at the printing points. Areas and halftone dots are transferred almost as if the substrate had an ideal flat surface. Rubber blankets age in terms of their physical and chemical properties and can also be damaged through prolonged use. They are therefore exchanged after a certain period of time.

handling

Assembly

The rubber blankets are usually attached to the cylinder using clamping rails or clamping systems . In web offset , blankets placed in front are common, which are also becoming increasingly popular in sheet-fed offset and offer advantages for quick changes. Calibrated sheets as a base are used to bring the surface of the rubber blanket to pitch circle diameter . Together with the base, the result is rubber cylinder elevators of different hardness. Both the rubber blanket and the hardness of the rubber cylinder lift determine the print quality. B. the exact transfer of the grid points .

storage

Rubber blankets should be stored away from light, heat and moisture and should lie "rubber layer on rubber layer" on top of one another.

literature

- Wolfgang Walenski: The web offset printing. History. Modern technology. Materials . Fachschriften-Verlag, Fellbach 1995, ISBN 978-3-931436-01-8 .

Individual evidence

- ↑ Helmut Kipphan (Hrsg.): Handbook of Print Media: Technologies and Production Processes . Springer-Verlag, Berlin / Heidelberg 2000, ISBN 3-540-66941-8 , pp. 253 .