Hollow jet pipe

Nozzles ( abbreviation : HSR) are valves of the fire brigade for extinguishing agent delivery (water or water-foam mixtures) which, besides the special radiant tubes , multi-purpose radiant tubes and foam jet pipes are used.

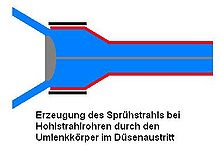

HSR are becoming increasingly popular. In hollow jet pipes, the water is passed through a ring-shaped nozzle, so that a hollow water jet is created which, however, can be filled with drops using certain techniques such as a fixed or rotating toothed ring, which allows better water distribution and thus more effective flue gas cooling. A full jet from such a ring jet nozzle is more stable (less rainfall) than a conventional full jet ("rod jet") and achieves a greater throw. It can also be used to achieve a spray cone with an opening angle of up to over 120 degrees. In most cases, the flow rate of the HSR can still be regulated, the water delivery does not have to be interrupted. In this way, the preceding nozzle operator can carry out a water-saving and dynamic extinguishing attack .

The fire brigades use a wide variety of jet pipe models and there has been a lively discussion for years as to which type of jet pipe is best suited for fire fighting .

Equipment differences

The nozzles can be equipped with a rotating or a fixed ring gear. In the case of a jet pipe with a rotating toothed ring, the jet is cut into fine water mist by the rotating toothed ring, which leads to better extinguishing success. However, this can lead to the flame being “sucked in” into the water cone, which takes some getting used to for the emergency services, but is also quite desirable in some situations, for example to catch and direct a gas flame. Depending on the design of the ring gear, the spray cone can be empty, partially or completely filled with water droplets. Beampipes that produce a filled cone will usually make more sense.

In the case of automatic pipes, the flow of the jet pipe is regulated within the specified limits by an integrated spring package, which opens further when the pressure rises and thus increases the flow while the pressure is kept constant. This means that the spray pattern and the throw do not depend on the flow rate. However, there must always be a sufficiently high pressure (around 6 bar) on the nozzle. However, these pipes are only suitable for internal attack to a very limited extent, as they no longer guarantee an insufficient amount of water for the squad to protect themselves at low pressure conditions (see LFKS RLP test).

The maximum flow rate varies greatly with different nozzle models. Hollow nozzles (with C-coupling) with a flow rate of around 130 l / min to approx. 300 l / min are common, but models are also available with a flow rate starting at 20 l / min or ending at over 1000 l / min. For pipes that are used for internal attack, a maximum flow rate of 130–150 l / min is completely sufficient, provided that no rollover prevention is to be carried out with these nozzles . Often, the high-jet nozzles also have a marking on the adjustment ring for the flow rate and the spray cone (similar to the rear sight and front sight of a target device) in order to be able to set the optimal setting for the internal attack. These markings are also shaped so that they can be felt blindly with gloves. For effective rollover prevention, nozzles with a water supply of at least 230 l / min are required, as otherwise the amount of water given off is not sufficient to cool the flue gas.

Special hollow jet pipes are also used on high pressure hoses .

Advantages and disadvantages compared to multi-purpose nozzles

- The infinitely variable adjustment of the spray cone and flow rate allows a quick and flexible adjustment to the conditions of a fire . Thus, major water damage can be avoided. However, the flexibility of the flow rate also has a disadvantage in terms of water consumption. If the machinist anticipates a water consumption of 135 l / min, but the team dispenses twice as much, the extinguishing water available may no longer be sufficient.

- The spray jet can cover a larger area (with an opening angle of over 120 degrees in some cases). On the one hand, this allows an improved cooling and extinguishing effect (especially when cooling off the smoke gas in the interior attack to prevent rollover ), and on the other hand, increased security for the attack troops (HSRs have effective "man protection", conventional multi-purpose nozzles without a special man protection shower).

- The spray jet consists of smaller droplets (≈ 0.3 mm) than with classic multi-purpose nozzles , this increases the surface of the droplets overall and thus also the cooling effect. The HSR droplets, which are somewhat larger than high and ultra-high pressure nozzles (droplets around 0.1 mm), are currently (2004/2005) viewed as an ideal compromise between cooling effect and penetration depth and are considered to be best suited for combating rollover .

However, the improved nozzle properties must be learned through special fire service training. Since many different hollow jet pipes are used, this training must always be based on the local equipment.

Usable jet nozzles are usually much more expensive to buy than multi-purpose nozzles (about twice to 10 times more expensive, depending on the model and manufacturer from ≈ 200 € / piece 2005), but significantly cheaper than high or maximum pressure extinguishing systems (which usually cost several thousand euros and are often very limited in their application).

Hollow nozzles can easily clog with heavily contaminated water (algae, dirt from open water, loosened incrustations from risers), the HSR should therefore always have a flush position.

Procurement guidelines

When purchasing HSR, the intended use should be carefully considered.

At the beginning of 2007, DIN EN 15182 with its four parts replaced DIN 14365 multi-purpose nozzles and DIN 14367 hollow nozzles. Part 3 includes the recommendation not to use the pipes according to Part 3 (e.g. multi-purpose jet pipes) for internal attacks. Part 1 does not include an electrical test. Instead, the recommendation was taken to maintain a distance of at least 1 m (up to 1000 V) with a spray jet of at least 30 °.

In Austria the guideline GA-21 is called "Purchase of hollow jet pipes" of the Austrian Federal Fire Brigade Association.

swell

- Holger de Vries: Fire fighting with water and foam. ecomed, Landsberg 2000.

- Holger de Vries: Investigations to optimize the fight against solid fuel fires with water and foam in mobile use by the fire service www.bod.de (dissertation on the topic)

- DIN 15182

literature

- Diverse: Hamilton - Handbook for the fire brigade. Boorberg Verlag, 21st edition, 2012, ISBN 978-3-415-04560-6 .

Web links

- Hollow jet pipes - structure of pipes - recommendations for procurement, by Silvio Faulstich, LFKS Rhineland-Palatinate ( PDF ; 0.6 MB)

- Water atomization in the jet pipe (Krüger, A., Radusch, R., Research Center for Fire Extinguishing Technology (Research Center for Fire Protection Technology, University of Karlsruhe), Westdeutscher Verlag, Cologne and Opladen 1956)

- Karlsruhe Institute of Technology (KIT) - Research center for fire protection technology: Comparison of the extinguishing effect of low-pressure and high-pressure water mist in fire fighting (PDF; 10 MB)

- Training material for the hollow jet pipe of the Hessian State Fire Brigade School (PDF 9.4 MB)

Individual evidence

- ↑ Austrian Federal Fire Brigade Association Guideline: ÖBFV-RL GA-21 Purchase of hollow jet pipes ( Memento from June 23, 2016 in the Internet Archive ) Status December 2007, approved February 26, 2008. - Download ( Memento from June 23, 2016 in the Internet Archive ) subject to a charge.