SAE J1939

The network protocol SAE J1939 describes the communication on a CAN bus in commercial vehicles for the transmission of diagnostic data (e.g. engine speed, temperature) and control information.

Application area

The protocol was defined by the international Society of Automotive Engineers (SAE) and works on the physical layer with CAN high-speed in accordance with ISO 11898. The main focus of application is on the drive train and chassis of commercial vehicles. The protocol is used in heavy vehicles for both on-road and off-road use ( construction machinery ). Related to J1939 are the ISOBUS according to ISO 11783 for agricultural machinery, NMEA 2000 for maritime use and the Truck & Trailer Interface according to ISO 11992. The FMS standard is also based on J1939 communication.

Connector pin assignment

| Pin code | function |

|---|---|

| A. | Ground / GND |

| B. | Battery + |

| C. | J1939 + (CAN H) |

| D. | J1939- (CAN L) |

| E. | J1939 shield |

| F. | J1708 + (Data A, ATA +) |

| G | J1708- (Data B, ATA-) |

| H | - |

| J | - |

Protocol description

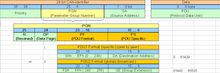

J1939 is a multimaster system with decentralized network management without channel-based communication. It supports up to 254 logical nodes and 30 physical ECUs per segment. The information is described as parameters (signals) and summarized on 4 memory pages (data pages) in parameter groups (PGs). Each parameter group can be identified by a unique number, the Parameter Group Number (PGN). Independently of this, a unique SPN (Suspect Parameter Number) is assigned to each signal.

Data transfer

Most of the communication takes place cyclically and can be received by all control units without an explicit request for data ( broadcast ). In addition, the parameter groups are optimized to a length of 8 data bytes . This enables a very efficient use of the CAN protocol. Certain information such as B. Configuration data or diagnostic data can also only be exchanged between two control units ( peer-to-peer ). The definition of the communication, broadcast or peer-to-peer, is a property of the parameter group used. In addition to the definition of which parameters are transmitted, the type of transmission also depends on the parameter group.

Transport protocol

If larger amounts of data have to be transferred, transport protocols (TP) are used:

- BAM ( Broadcast Announce Message ) and

- CMDT ( Connection Mode Data Transfer ).

With the BAM TP, the data is transmitted to all bus participants via broadcast. There is no control data flow ( handshake ) between sender and receiver . With the CMDT TP, the data is exchanged between exactly two control units. The control data flow that takes place here enables communication to be restarted without a complete repetition of the data transmission in the event of an error. The CMDT TP also enables the recipient to confirm receipt of the data.

Decentralized network management

So that peer-to-peer communication is even possible on a CAN network, each control unit must be assigned a unique address in the range from 0 to 253. In order to avoid two control units with the same address wrongly occurring during operation, a sophisticated strategy is required - network management (NM). With J1939 the NM is organized decentrally. In other words, each control unit must implement a minimum functionality of the NM. The tasks of the NM are:

- Resolution of address conflicts (minimum requirement)

- Ongoing check as to whether control unit addresses are assigned twice in a network (minimum requirement)

- Change of control unit addresses during runtime

- Unique identification of a control unit with the help of a globally unique name

- This name is also used to identify which functionality a control device has in the network

SAE documents

The standard is divided into the following layers (documents):

| standard | description |

|---|---|

| SAE J1939 | Recommended Practice for a Serial Control and Communications Vehicle Network |

| SAE J1939-11 | Physical layer - 250 kBits / s, shielded twisted pair |

| SAE J1939-13 | Off-board diagnostic connector |

| SAE J1939-15 | Reduced Physical Layer, 250 kBits / s, Un-Shielded Twisted Pair (UTP) |

| SAE J1939-21 | Data Link Layer |

| SAE J1939-31 | Network Layer |

| SAE J1939-71 | Vehicle application layer |

| SAE J1939-73 | Application Layer - Diagnostics |

| SAE J1939-81 | Network Management Protocol |

CiA documents

The association CAN in Automation (CiA) eV describes in the specification CiA-413 gateways from J1939 to CANopen and in the document CiA-602 a mapping of J1939 messages to CAN-FD.

literature

- Werner Zimmermann, Ralf Schmidgall: Bus systems in vehicle technology - protocols, standards and software architecture . 4th edition. Vieweg + Teubner, 2010, ISBN 978-3-8348-0907-0 .

swell

Web links

- SAE J1939 Standards Collection on the Web

- Free e-learning J1939

- An introduction to the protocol: Application Note Introduction J1939 (PDF file; 139 kB)