Ball lock

The ball lock is a lock design that was mainly used in guns in the period from around 1890 to around 1924.

Basic requirements

The breech of the gun closes the barrel at the rear and must divert the forces of the recoil through the barrel into the carriage structure when a shot is fired. To do this, it has to lock reliably with the pipe. Together with the cartridge, it must seal the tube gas-tight in order to use the propellant charge as completely as possible. The breech should provide protection against accidental firing. In principle, it must be possible to open and close the lock quickly with just a few hand movements when manually operated. Low weight and small dimensions are still required in order to minimize the dead tube length, that is, the length of the tube behind the cartridge or powder chamber. This dead pipe length together with the return path of the pipe determines the maximum pipe elevation for a given carriage construction.

history

Muzzle loaders remained the dominant form of construction for artillery pieces until the middle of the 19th century. Since artillery battles were conducted both on land and at sea from a few hundred meters away, the shooting performance was sufficient for the requirements of the time. Effective armor for warships appeared from the middle of the 19th century. Penetrating this armor with conventional full bullets was practically impossible. On land, too, with the abandonment of conventional linear tactics, a higher range and penetration performance of the artillery was required. However, this could only be achieved with long projectiles and the associated use of drawn pipes. However, loading these long storeys through the mouth was difficult. Because of the small difference between the caliber of the grenade and the caliber of the barrel, these had to be pressed into the barrel with considerable effort. This was practically impossible, especially with larger calibers - and thus potentially long-range guns. In any case, the cadence of the guns sank to unacceptable values. An increase in the caliber difference was prohibited due to the poorer utilization of the propellant charge. By Giovanni Cavalli and Martin von Wahrendorff in Piedmont and Sweden and William Armstrong in Great Britain, modern breech-loading guns were constructed from the end of the 1840s . Since the barrel was inevitably open for reloading, it had to be closed with a lock during the shot. In order to enable reloading, this slide had to be movable. Initially, simple, manually operated drop block locks were used. Such guns were introduced by the Royal Navy and British Army in Piedmont, Sweden and Great Britain. However, Great Britain stopped producing such breech-loaders again after a short time, as production and maintenance were too cost-intensive and offered little tactical advantages over muzzle-loaders. A disadvantage of the breech-loaders at that time also proved to be the fact that a larger propellant charge could be used with the muzzle-loaders, which meant that their range and penetration performance were higher. The reason for the lower efficiency of the breech loader was the strain on the tubes and the use of fast-burning propellant powder, which generated a higher maximum pressure.

In the 1860s, the piston lock, a lock design that was gas-tight and enabled relatively quick reloading, was made ready for use. With it, as with the screw closure, the closure is inserted into the tube from behind in the direction of the longitudinal axis and locked. In contrast , with the wedge lock , which Krupp and Erhardt developed to readiness for use, especially in Germany , a round or flat lock wedge is pushed into the pipe and locked transversely to the pipe's longitudinal axis. The French designer M. Canet (1846–1913) developed a completely different locking system with the ball lock. The system was used, among other things, with a French field cannon of 7.5 cm caliber, but also with Italian ship and anti-aircraft guns of 7.5 to 10.2 cm caliber such as the Cannone da 76/45 R. (egia) M. (arina) Mod. 1911 . The Schneider-Creusot company, which manufactured this weapon, produced the Cannone da 102/35 , Cannone da 102/45 and the 90 mm flak model 1924 for export .

Construction principle

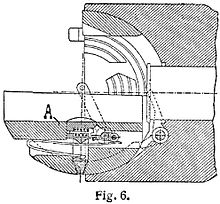

The Canet ball lock consists of a hemisphere (A), the diameter of which is slightly larger than the inner diameter of the pipe. For reloading, the hemisphere is rotated 90 degrees downwards, the flat bottom of the hemisphere reveals the cross-section for reloading. Then the hemisphere is turned back 90 degrees and seals the pipe to the rear. A quarter turn of the handwheel or locking lever is sufficient to open or close the lock. Since the firing pin lies in the movable locking part, it is only released when the lock is closed. The grenade cartridges used must have a hemispherical case base so that they can be supported with the full cross-section on the breech. The gas tightness and the locking of the closure and the need for special cartridges are problematic. Additional elements must be provided to lock the closure and to eject the cartridge. The advantages of this design are the short reloading time and the possibility of automation.

Individual evidence

- ^ Lueger, Otto: Lexicon of the entire technology and its auxiliary sciences

literature

- Lueger, Otto: Lexicon of the entire technology and its auxiliary sciences, Bd. 8 Stuttgart, Leipzig 1910.