Plate chain

A link chain is a special type of drive chain in mechanical engineering and vehicle technology .

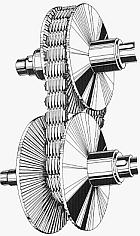

The positive-locking inverted tooth chain consists of cross bolts with a number of side-by-side straps that carry a tooth profile on one side . The force is transmitted from the tabs to normal gears.

In PIV gears (“Positive Infinitely Variable”), lamellar chains are used: the link plates have rectangular holes in which laterally sliding sheet metal lamellas are located, which engage in radial grooves on the V-belt pulleys. "Grooves" and "teeth" are opposite each other on the pulleys. These chains work positively, but can slip if overloaded.

Frictionally engaged plate-link chains in Audi's Multitronic transmissions have rocker joints. The force is transmitted to the flanks of the bevel gears via the lateral surfaces of the pivot pins. The conical discs can be adjusted axially in order to continuously change the translation. The individual links of the chain are not exactly the same length, and the different lengths are arranged randomly to make the gear noise more pleasant (hissing instead of whistling).

Lamella belts and V-belts are also used for mechanically adjustable continuously variable transmissions ( CVT transmissions ). CVT transmissions are controlled manually or automatically. The speed or torque can be adjusted both when idling and under load. The spread , i.e. the ratio of the largest and smallest gear ratio of link chain drives, reaches around 7 in automobiles. Slat belts generally have less spread because of the larger minimum radius of the bevel gear. Variomatic gearboxes with plastic V-belts on scooters (approx. 3) have even less spread.