Load iron

Load irons or weighting irons are placed as load bodies on the upper box of horizontally divided casting molds in order to compensate for the buoyancy and gas pressure forces when filling ( casting ) a casting mold.

In the case of molds, the individual parts of which cannot be clamped or only insufficiently clamped, this weighting is the only way to guarantee the dimensional accuracy of the casts. The pressure exerted by the melt increases with the height of the metal column in the sprue above the mold and with the base area of the upward-poured side of the casting geometry. If the mold has a core, this also causes an Archimedean buoyancy force to act vertically upwards, which is usually diverted into the upper case of the mold via core marks, as the core bearings in molds are called.

Dimensioning

To determine the required load weight, the total buoyancy force acting on the upper case is calculated:

- Lifting force against the upper case

- Buoyancy force of the core

The lifting force is calculated according to:

- Area of the casting projected against the upper box

- Height of the upper box

- Density of the melt

- Gravitational acceleration

The buoyancy force of the core corresponds to the weight of the melt volume displaced by the core. The density of the core itself is neglected:

- Volume of the mold core

- Density of the melt

- Gravitational acceleration

For coreless molds, the load weight required to support the upper case during casting can be roughly determined using the following rule of thumb:

- = necessary load weight in kg,

- = area of the casting projected against the upper box in dm²,

- = Height of the upper box in dm,

- = Density of the melt in kg / dm³,

- = Safety factor> 1

- = Weight of the upper box in kg

execution

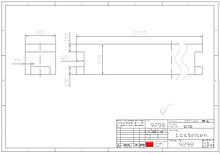

The material, geometry and dimensions of load bars are arbitrary and are adapted to the requirements and proportions of each company. However, they should be able to be transported safely with hoists and offer the possibility of stacking (see drawing for example).

Individual evidence

- ^ Stephan Hasse: Foundry Lexicon 2008. 19th edition. Fachverlag Schiele & Schoen, Berlin 2007, ISBN 978-3-7949-0753-3 , page 139.

- ↑ Primary molding by casting ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. . HS Pforzheim, Department of Mechanical Engineering, Production Technology I, WS 2007/2008. Retrieved August 20, 2010.

- ^ A. Herbert Fritz, Günter Schulze (Ed.): Manufacturing technology. 9th edition. Springer-Verlag, Berlin Heidelberg, 2010, ISBN 978-3-642-12878-3 , page 11.