Multi-seat valve

Multi-seat valves , also block valves or multi- way valves, are used to shut off or control complex liquid flows in sterile areas of the beverage and food industry as well as in the pharmaceutical and fine chemical industries . They often replace combinations of several single-seat valves in the aseptic area.

Application and function

Particularly in the production of active pharmaceutical ingredients, but also for many other aseptic processes, systems require a high degree of customization, because the large number of variants can hardly be covered by standardized components. As a consequence, valve manufacturers are required to have a high level of competence in the area of design and close interaction between the planner and manufacturer in the planning phase of (aseptic) systems. This is the only way to B. ensure that the system can be emptied with the greatest possible compactness. This is primarily a result of the widely differing biotechnical processes due to the product and the special features in the processing and combination of ingredients for the highly sensitive end products.

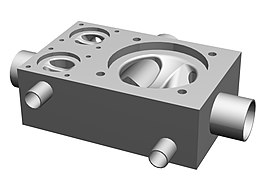

Similar to the single-seat valve, the multi-seat valve also consists of the valve housing, but equipped with several membranes and drives, and in many cases one control and feedback unit per drive.

With the exclusive use of straight-way valves , i.e. membrane valves that shut off the flow in a pipeline with a single membrane, the possible variations would be limited to the different nominal widths of the connections. Although the combination of such single-seat valves, which can also have a T- or Y-shape, can be used to design complex process sequences and distributions, multi-seat valves with specific advantages for the aseptic process are preferably used for this purpose. Due to the fact that they are made from a forged block and their very compact design, these valves are often referred to as "block valves". With multi-seat valves, there is an almost infinite variety of variations.

Some of the advantages of the multi-seat valve are immediately apparent: It saves space so that the system or sub-system takes up less space. In addition, the area in contact with the medium within the valve combination decreases considerably compared to the ring design.

The compactness of a multifunctional multi-seat valve and thus also the system can be strongly influenced by the size of the available drives . Multi-seat valves with particularly slim drives that do not protrude in diameter beyond the dimensions of the diaphragm offer considerable advantages.

Important manufacturers for multi-seat valves on the German and European market are u. a. GEMÜ , Bürkert , SED and SISTO .

- Comparison between valve combinations and multi-seat valves

Cleanability

Due to the compact arrangement of the multi-seat valve, the area in contact with the medium within the valve combination is significantly reduced compared to the ring design. This is of great advantage for cleaning and emptying. In addition, the multi-seat valve has significantly fewer sub-areas that are rarely flushed through or in which the product can collect. With regard to the purging of valve combinations, the “3-D rule” must generally be observed. After that, the length of a branch up to the valve seat should not exceed three times the diameter of the branch. With a multi-seat construction, "dead branches" are avoided and microbial contamination in the standing medium is significantly reduced.

With the correct installation of the diaphragm valve in a defined inclined position and with the appropriate quality of the inner metal surface, a modern internal geometry enables the multi-seat valve to drain completely, so that the medium flows completely and completely out of the valve housing without any additional measures.

Drive types

Due to the mostly complex structure of multi-seat valves, pneumatic drives are used in most cases . Depending on the design, pneumatic drives can be divided into piston and diaphragm drives. The advantages of the piston drive lie in the compact design, which pays off especially in multi-seat constructions. Multi-seat valves can thus be made more compact and lighter. Because the piston drive has a smooth surface without areas that are difficult to clean, it is usually easier to clean outside than the diaphragm drive. Its advantages, however, are the more cost-effective drive structure.

See also

Individual evidence

- ↑ Applications - SISTO Armaturen SA In: SISTO Armaturen SA ( sisto-aseptic.com [accessed on February 26, 2018]).

- ↑ Diaphragm Valves for Aseptic Processes . In: SZ Scala GmbH (ed.): The library of technology . tape 389 . Verlag Moderne Industrie, Munich 2017, ISBN 978-3-86236-104-5 , pp. 11-12 .

- ↑ Products - SISTO Armaturen SA In: SISTO Armaturen SA ( sisto-aseptic.com [accessed on February 26, 2018]).

- ↑ Bernd Thier: Industrial valves: components of pipeline technology . 5th edition. Vulkan-Verlag GmbH, Essen, ISBN 978-3-8027-2712-2 , p. 534 .

- ↑ Ralph-Harry Klaer: Practical Manual Industrial Valves 2003 . Ed .: Wolfgang Mönning. Vulkan-Verlag GmbH, Essen, ISBN 978-3-8027-2729-0 , p. 61 .

- ↑ Diaphragm Valves for Aseptic Processes . In: SZ Scala GmbH (ed.): The library of technology . tape 389 . Verlag Moderne Industrie, Munich 2017, ISBN 978-3-86236-104-5 , pp. 36-38 .

- ↑ Drives - SISTO Armaturen SA In: SISTO Armaturen SA ( sisto-aseptic.com [accessed on February 26, 2018]).