Diaphragm pump

The diaphragm pump is a machine for pumping liquids or gases, which is particularly insensitive to long-term stress and contamination in the conveyed material.

Its functional principle is a modification of the piston pump , but the medium to be conveyed is separated from the drive by a membrane . It is also similar to the heart , but instead of a mechanically moved membrane it uses contracting muscles.

The advantage of this pump is that the separating diaphragm shields the drive from harmful influences of the pumped medium, for example sludge or impurities in the pharmaceutical or food industry. One of the major disadvantages of the conventional piston pump, the problem of the piston sealing, is thereby solved.

The diaphragm is deflected either hydraulically, pneumatically, mechanically or electromagnetically.

Areas of application

The diaphragm pumps are used where a leak-free pump design is particularly important. For example, they are used where dangerous sludge has to be pumped or dry running is to be feared. They are useful for pumping abrasive fluids because they do not have any rubbing seals and because of the low maintenance requirements generally for slurries.

They are not well suited for higher pressures; in the past they were often used as fuel pumps in cars.

On the other hand, there are diaphragm pumps as vacuum pumps . They are used specifically when the vacuum has to be oil-free. Since diaphragm vacuum pumps are very insensitive in comparison to other vacuum pumps, they have established themselves as standard pumps for rough and fine vacuum in chemistry and process engineering . With diaphragm pumps, vacuums of up to about 0.5 mbar can be generated.

Mechanically

Mechanical diaphragm pumps are somewhat more efficient than compressed air diaphragm pumps, especially if you add the energy loss due to the generation of compressed air, but they still cannot come close to the efficiency of a hydraulic diaphragm pump.

Hand diaphragm pump

In most cases these are driven by hand using a pump lever. They are used z. B. to generate a vacuum for centrifugal pumps or for pumping small amounts of liquid. They are also common equipment used by fire brigades when deploying dangerous goods. Another example of an early form of the diaphragm pump is the bellows .

Mechanical transmission

In most cases, these are driven by an electric motor via a connecting rod and an eccentric . They are used z. B. in leak detection devices to maintain the negative pressure.

Pumps of this type have been used as fuel delivery pumps in motor vehicles for decades. Here they were operated by the engine's camshaft. In single-cylinder and two-stroke engines, the diaphragm was occasionally actuated directly by the negative pressure in the intake tract.

One area of application for this pump is, for example, the diaphragm ventilation pump in the fire service.

Micromembrane pumps

Disc-shaped piezo actuators , which can be mounted directly on the membrane, are used in micromembrane pumps . They are used for the continuous delivery or dosing of smaller amounts of liquid.

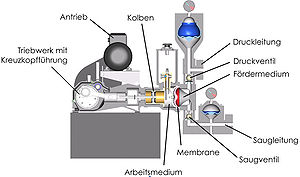

Hydraulic: piston diaphragm pump

Hydraulic pumps are required for higher pressures. The counter pressure of the hydraulic fluid relieves the diaphragm and thus increases its service life.

With a piston diaphragm pump, the oscillating movement of the piston is transmitted to the diaphragm via a working medium. The working fluid used is water with a water-soluble mineral additive or a hydraulic oil. The operation of the piston diaphragm pump can be viewed in a similar way to that of a pure piston pump, since the movement of the piston directly causes a deflection of the diaphragm and thus induces suction and pressure pulses due to a constant volume of liquid between the piston and the diaphragm. By using a liquid, however, the diaphragm is loaded over the entire surface and there is no point loading of the diaphragm as with a pure diaphragm pump.

Pneumatic

They consist of a double housing containing two membranes connected by a connecting rod. These are acted upon on the outside by the pumped medium and on the inside by the compressed air. When the membrane has reached its end position, a valve is actuated via the connecting rod, which diverts the compressed air to the other membrane. A compressed air diaphragm pump transfers the air pressure to the pumped medium without any loss. As the only positive displacement pump , the delivery volume is set by throttling on the pressure side and can therefore be adjusted very precisely. However, at the moment of reversal, there are relatively strong fluctuations in the delivery pressure (no pressure surges, since the pressure drops, but cannot rise above the air pressure), which can interfere with some applications. In fuel pumps for two-stroke engines (AWE Wartburg, DKW), the pressure vibrations of the crankcase were used for pneumatic drive.

Another disadvantage is the relatively high energy requirement, since as much compressed air is required as is conveyed with the pump.

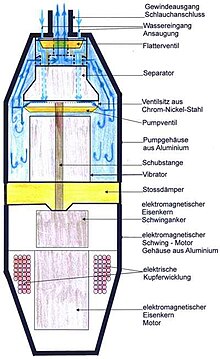

Electromagnetic (oscillating armature pump)

These types of diaphragm pumps use a vibrating armature that is moved by an alternating magnetic field.

The electromagnetic pumps are significantly more efficient than the pneumatic pumps.

literature

- Gerhard Vetter: Leak-free pumps, compressors and vacuum pumps. Vulkan-Verlag, 1998, ISBN 3-8027-2185-3 , pp. 251-260.

Web links

Individual evidence

- ↑ Ulrich Harten: Physics: An introduction for engineers and natural scientists. Gabler Wissenschaftsverlage, 2011, ISBN 978-3-642-19978-3 , p. 90.

- ↑ Ulrich Harten: Physics: An introduction for engineers and natural scientists. Gabler Wissenschaftsverlage, 2011, ISBN 978-3-642-19978-3 , p. 90.

- ↑ Gerhard Vetter: leak-free pumps, compressors and vacuum pumps. Vulkan-Verlag, 1998, ISBN 3-8027-2185-3 , p. 251.

- ↑ Vacuum pumping station for laboratory use , accessed on March 10, 2017.

- ↑ Gerhard Vetter: Rotating displacement pumps for process technology. Vulkan-Verlag, 2006, ISBN 3-8027-2173-X , p. 28 f.

- ↑ Gerhard Vetter: leak-free pumps, compressors and vacuum pumps. Vulkan-Verlag, 1998, ISBN 3-8027-2185-3 , p. 252.

- ↑ Gerhard Vetter: leak-free pumps, compressors and vacuum pumps. Vulkan-Verlag, 1998, ISBN 3-8027-2185-3 , p. 251.

- ↑ Gerhard Vetter: leak-free pumps, compressors and vacuum pumps. Vulkan-Verlag, 1998, ISBN 3-8027-2185-3 , p. 251.