Oscillating armature pump

The oscillating armature pump is a type of pump that is driven by a vibrating armature instead of a rotating motor. It can be found in two main designs: as a diaphragm pump and as a vibration pump .

Working principle

One with serving as a driving AC voltage impinged coil whose magnetic field to a swinging mounted armature acts. In oscillating armature diaphragm pumps, the armature acts on the pump diaphragm via a lever. The structure is thus very similar to that of an alternating current bell . Just like the AC bell, the oscillating armature pump works with the frequency of the AC voltage with which it is operated. In the vibration pump, the armature is surrounded directly by the pumped medium and also serves as a pump piston.

properties

Because of the few moving parts (no motor in the classic sense), vibrating diaphragm pumps can achieve service lives of over 60,000 operating hours if carefully designed . The noise development is extremely low with many designs. The disadvantage is that it can only be operated with alternating current. If a vibrating armature pump is to be operated with direct current , an oscillator is essential . Some designs have difficulty starting against pressure. The pumping media are mostly gases or air, but also water (well water from deep wells or ponds, streams, etc.).

Oscillating armature pumps, which have a natural resonance that is adapted to the oscillation of the alternating current to increase efficiency, have the disadvantage that this oscillation of the device generates a higher noise level.

Designs and applications

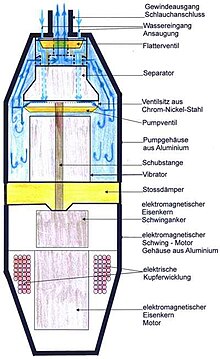

Oscillating armature pump (vibration pump)

An AC-powered electromagnet (2) generates an oscillating magnetic field via a yoke in an internal air gap , which causes a ferromagnetic armature (6) to oscillate against a compression spring (5). This armature also represents the piston , through whose central bore water can flow into the pump chamber (8). If the piston swings out of the air gap of the electromagnet due to the spring force, a valve (7) closes the bore in the piston and another valve (9) opens the pump chamber in the direction of the outlet when there is sufficient pressure. If the piston is pulled back into the air gap by the magnetic field, the outlet valve (9) closes again and the cycle starts all over again. To decouple the environment from the strongly vibrating pump, they are supported by elastomer bearings (1,11).

Due to their simple design, oscillating armature pumps are used in almost all portion coffee machines (e.g. Senseo , Nespresso or Dolce Gusto ) and many household espresso machines to generate the required water pressure between 2 and 16 bar with a flow rate of around 0.2 - 1.2 l / min used. Vibration pumps are not often run dry and often have no 100% duty cycle , so they are often on the coils of the electromagnets thermal switch or thermal fuses attached. The market leader Ulka alone, who made this type of pump suitable for the masses in the mid-1970s, produced more than 10 million pumps of this type in 2003.

Vibrating armature diaphragm pump

With the classic design of the oscillating armature pump with diaphragm, the pressure range is typically around 100 mbar, in exceptional cases up to approx. 350 mbar with delivery rates usually below 20 liters per minute. They are used as aquarium pumps, pond aerators, but also in gas analyzers and exhaust gas analyzers. The designs for deep wells and water pumps are designed to match the diameter of the well pipes and have an average delivery rate of approx. 20 ltr / min to 25 ltr / min. The delivery rate and the working head of an average of 25 meters to 30 meters depends on the quality of the work. The material used is mostly made of aluminum.

By installing a pump valve seat made of chrome-nickel steel , only built into the diaphragm pumps , wear was reduced to a minimum.

Linear diaphragm pump

In the linear diaphragm pump, an axis in an annular coil is excited to vibrate in the axial direction. This is done in an advantageous manner by attaching an iron ring to a non-magnetic axle, which swings into an air gap. The membrane is attached to one or both ends of the axle. The version with two diaphragms is also called a double-head linear pump. Particularly powerful versions work with mutually polarized, ring-shaped permanent magnets on both sides of the iron ring.

Large double-head linear diaphragm pumps achieve up to 100 liters of air per minute at final pressures of up to 600 hPa. This design is used as a clarifier aerator, in process technology, fuel cell technology or for electrolyte circulation in large batteries. However, there are also miniature designs for pumping very small amounts of liquid and gas.

References and comments

- ↑ Technical description e.g. B. in the disclosure DE102005048765A1 "oscillating armature pump"

- ↑ Technical data e.g. B. for ULKA E-model series (accessed on August 7, 2013)

- ↑ Interview with the company founder Giampiero Rossi, Jonathan Bell, " Talking with the electric: Mr. Rossi " in Tea & Coffee Trade Journal, ISSN 0040-0343 of November 20, 2003, accessed on August 9, 2013.

- ↑ In some articles it says that Ulka practically invented the vibration pump, but it already existed before, e.g. B. DE000001653447B suggests. The Ulka company seems to have significantly simplified and reduced the structure of the magnetic circuit in particular.

- ↑ For example in type MA-o1 & MA-o2 ( Memento of the original from December 5, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. .

- ↑ http://www.gd-thomas.de/productcategorylist.aspx?id=10342 Description with graphics.