Natural circulation evaporator

A natural circulation evaporator or self- circulation evaporator is an evaporator whose circulation is generated without a circulation pump through natural convection due to the formation of bubbles. It is mostly used in rectification . Natural circulation evaporators are used in the sugar industry to evaporate juices containing sugar.

principle

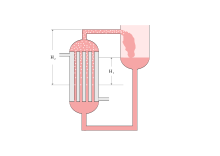

The transfer of heat causes bubbles to form in the liquid as it evaporates. The bubbles create buoyancy that promotes the liquid upwards. The buoyancy arises from the fact that the mean density of the vapor / liquid mixture is lower than that of the pure liquid. This mechanism creates a circulating flow that always delivers fresh liquid to the evaporator without the need for a pump, as is the case with the forced circulation evaporator , which means savings in investment and operating costs. The lower the viscosity of the liquid to be evaporated, the better the circulation.

A certain immersion depth H 1 is required for a natural circulation evaporator to work properly . The hydrostatic pressure resulting from this height with the density of the pure liquid must be higher than the hydrostatic pressure of the column H 2 and the mean density of the mixture.

scope of application

Natural circulation evaporators are used from pressures of approx. 300 mbar abs and can be used particularly in the overpressure range. In addition to the diving depth, it is crucial that bubbles can form. If the hydrostatic pressure exceeds the vapor pressure of the liquid at the given temperature, the liquid cannot evaporate and bubbles do not form. The circulation then does not work. This can happen especially with a higher vacuum. If the temperature difference between the heating and evaporation sides is too low, the formation of bubbles can also be hindered.

See also

literature

- Klaus Dialer: The heat transfer in the natural circulation evaporator . Dissertation ETH Zurich 1983.

Individual evidence

- ↑ a b c d Klaus Dialer: The heat transfer in the natural circulation evaporator . Dissertation ETH Zurich 1983. pp. 3–5.

- ↑ Ralf Goedecke: Fluid Process Engineering: Fundamentals, Methodology, Technology, Practice . Wiley-VCH-Verlag, Weinheim 2006, ISBN 978-3-527-31198-9 , p. 614.

- ↑ Dieter Osteroth (Ed.): Pocket book for food chemists and technologists . Volume 2, Springer Verlag, Berlin 1991, ISBN 3-540-53441-5 . P. 232.

- ↑ Volker Gnielinski, Alfons Mersmann, Franz Thurner: Evaporation, crystallization, drying. Springer Fachmedien GmbH, Wiesbaden 1993, ISBN 978-3-540-67064-3 . P. 36.

- ↑ Ralf Goedecke: Fluid Process Engineering: Fundamentals, Methodology, Technology, Practice . Wiley-VCH-Verlag, Weinheim 2006, ISBN 978-3-527-31198-9 , p. 618.