Keyseating machine

A keyseating machine , often also called utility drawing machine or keyway drawing machine , is a machine tool for metal-cutting metalworking with vertical-linear movement of the draw knife . The English name is Keyseating machine . It is driven by hydraulics or electromechanically by means of ball screws .

Manufacturer

Well-known manufacturers of keyseating machines are the Leistritz Group , Christian Gierth GmbH, Mario Beyer GmbH and Maschinenfabrik Frömag. Other well-known manufacturers were Balzat, Stuhlmann, WGW or TGW.

construction

The machine is usually divided into the main parts:

- Machine body

- Hydraulics or ball screws

- control

- Machine table

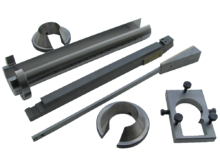

- Tool set consisting of:

- Tool guide

- Pushrod

- Knife holder

- centering

- Spanner

- Chip deflector

- Draw knife

- Special accessories

- Dividing device for the production of gears

application

In several vertical double strokes, the groove is drawn chip by chip into the workpiece with the single-edged draw knife. The workpiece, the centering and the tool guide are statically located on the machine table. The knife holder and the feed rod together make the vertical cutting movement. The chip thickness is delivered by the wedge of the feed rod, which is pulled down relative to the pull knife before each new downward stroke. The width tolerance of the groove is achieved by the appropriately sharpened pull knife. The workpiece and the pull knife are picked up exactly in the center of the tool guide. The positive connection between the workpiece and the tool ensures the exact position of the groove in the bore and the parallelism of the axes. The guided tool ensures a high surface quality. Simple manual or automatic dividing devices integrated into the machine control are used to produce multiple grooves, spline hub profiles and toothing.

Cutting speed

The electromechanical machine reaches cutting and return stroke speeds of 48 m / min. However, compared to the hydraulic drive, significantly longer distances are required to accelerate and brake. This means that the maximum speed only comes into play with larger strokes (approx. 300 mm or more). Hydraulic keyseating machines achieve a cutting speed of 20 m / min and a return stroke speed of 30 m / min with very short acceleration and deceleration distances. In practice, it has been shown that high return stroke speeds (especially with tough materials) lead to built-up edges and thus a shortened service life of the pull knife. Because of this, the maximum return stroke speed can often not be used sensibly. This can be counteracted by using coated pull knives or a fully synthetic emulsion as a cooling lubricant.