Rib (technique)

In technology , a rib is a piece of plate with which another, often flat component is made more stable against deformation . It is attached vertically to such a plate-shaped component, after which potential bending or arching out of the plane of the plate is reduced. Very often a rib is also placed between two parts of the body so that they can bend less against each other. The axis of reduced bending is perpendicular to the plane of the ribs.

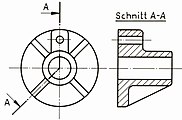

In technical drawings , a guided in the ribs level interface not hatched. Since ribs are often very large in relation to the entire component, this avoids the impression that the component is very massive (large in volume and mass).

In civil engineering , e.g. B. in the construction of vaults, the vault ribs are not reinforcing, but independent and self-supporting components.

In heating and cooling technology , thin metal sheets are attached to power components for thermal contact with the air, which are also known as fins. Examples are power transistors , finned tubes, and finned heating and cooling sinks.

Vault ribs as edges between the vault surfaces, which are supported by the ribs

Finned tubes : numerous, closely spaced annular sheets for the heat exchange between a medium in the tubes and the air

Remarks

- ↑ Der Neue Brockhaus , fifth edition, 1975, rib: 3) a transverse reinforcement in flat components

- ↑ With the material pattern model , the cut is not made through a rib if possible, in order to prevent the knife or saw from slipping out.

- ↑ Der Neue Brockhaus , Rippe: 2) ridges of a vault

- ↑ Der Neue Brockhaus , Rippe: 6) Parts of a radiator