Finishing (textiles)

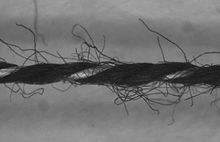

In the textile industry, sizing is the application of a protective film to protect yarns that are to be processed into woven textiles in the subsequent production step. The sizing agents are intended to protect the yarns from splicing and chafing during weaving. The choice of sizing agent depends on the type of yarn to be protected and the type of fiber from which the yarn is made.

Finishing

Before the weaving process , a protective film, the so-called size , is applied to strengthen the warp threads . As sizing agents are starch (often in oxidatively more open form), starch (carboxymethyl starch), higher alcohols , polyvinyl alcohol , acrylic acid (and their salts) or cellulose derivatives (eg. B. carboxymethyl cellulose ) are used.

Desizing

After creeping and weaving, the treated fabrics are usually removed before further processing (dyeing). This is done using desizing agents.

- Methods of desizing

- hydrolytic : with acids

- oxidative : with persulfates

- enzymatic : for starch sizes

- thermal: for glass fibers

- mechanical: for water-soluble sizes, by washing with hot water

The aim of the desizing process is, on the one hand, to eliminate the hard feel and, on the other hand, to improve the net and through-dyeing behavior of the fabric.

Colored finishing

Here the sizing agent remains on the goods, which are given a certain finishing effect.

Individual evidence

- ↑ a b c Brockhaus ABC Chemie , VEB FA Brockhaus Verlag Leipzig 1965, pp. 1244-1245.

- ↑ Keyword "sizing agents" in: Hans-Dieter Jakubke, Ruth Karcher (coordinators): Lexicon of Chemistry in three volumes, Spektrum Verlag, Heidelberg, Volume 3, 1999, ISBN 3-8274-0381-2 , p. 207.