glass fiber

A glass fiber is a long, thin fiber made of glass . During production, thin threads are drawn from a glass melt and processed into a large number of end products.

Glass fibers are used as optical waveguides (for data transmission and flexible light transport), as rovings or as textile fabrics (for heat and sound insulation ) as well as for glass fiber reinforced plastics . These are among the most important construction materials today. They are aging and weather resistant, chemically resistant and non-combustible. Their high modulus of elasticity is used to improve the mechanical properties of plastics.

history

Almost 4000 years ago, the Phoenicians, Greeks and Egyptians used melted glass threads to decorate vessels. In 1713 Ferchault de Reamur pointed out the possibility of weaving fine glass yarns. Glassblowers from the Thuringian Forest were also producing so-called fairy or angel hair as early as the 18th century. At first only used as a decorative medium, the possibilities of fibers (e.g. thermal insulation of glass wool) were gradually discovered in Thuringia (Lauscha, Steinach). In the Haselbach glass factory founded by H. and J. Schuller in 1896 (today Vitrulan Technical Textiles GmbH ), spinnable glass threads with a precisely defined diameter were first produced as rolled goods in the 1930s. The rod drum pulling process developed and used for this purpose was registered for a patent in the 1930s.

Manufacturing

Depending on the intended use, glass fibers are drawn from a preform or drawn from a glass tub through heated nozzles.

A preform is an enlarged "image" of the later cross-section of optical fibers. They contain the starting materials in their arrangement and structure (see also photonic crystal ).

The nozzle method uses heated nozzles (metal blocks or bushings made of platinum / alloys heated by direct current flow with thousands of holes) through which the glass emerges at a defined temperature (e.g. 1200 ° C) and is immediately drawn out thin and long and cooled . The withdrawal speed is significantly higher (e.g. 500 m / s) than the exit speed from the nozzles.

Both processes have in common the dependence of the final diameter on the starting temperature and the drawing speed.

The starting materials are mainly silicon dioxide , Al 2 O 3 , MgO , B 2 O 3 , CaO , whereby the starting materials and their purity determine the optical, mechanical and chemical properties.

Both textile and optical fibers must be protected immediately after being drawn, otherwise they would break or rub against each other. This so-called sizing is usually a company secret of the manufacturer and consists of a coating and / or an adhesion promoter. For example, it is also based on the synthetic resin used , with which the rovings are processed into glass fiber reinforced plastics (GRP). Alkoxysilanes as adhesion promoters have, for example, hydrophilic (bonds to the glass) and hydrophobic (bond to the resin) atomic groups.

Use as a light guide

In the fiber direction, light can propagate almost unhindered in glass fibers. The light is guided in the fiber by a refractive index that decreases radially outwards , continuously or in steps. This property as a light guide is used in many technical applications.

Data transfer

Glass fibers are used, among other things, as optical waveguides in glass fiber networks for optical data transmission . Compared to electrical transmission, this has the advantage of a considerably higher maximum bandwidth . More information can be transmitted per unit of time. In addition, the transmitted signal is insensitive to electrical and magnetic interference fields and is more secure against eavesdropping.

Lighting, decoration, art and architecture

The thyssenkrupp test tower is wrapped in fiberglass

Optical fibers are used in a variety of lamps and lighting installations today, the fibers being used not only for light transport but also as radiating elements themselves. An unusual application is the production of translucent concrete : the incorporation of three to five percent glass fiber creates translucent concrete elements through which light , shadows and colors can be seen up to a wall thickness of 20 cm ( see also: Litracon ). But buildings are also sheathed with fiberglass to beautify them. In the area of wall coverings, fiberglass wallpapers are also available.

Lighting and imaging in medicine and metrology

Glass fibers and fiber optic bundles are used for lighting and imaging purposes e.g. B. used on microscopes , inspection cameras or endoscopes or with cold light sources ( see also: fiber optics ).

Sensors

Glass fibers are increasingly used in measurement technology. So are fiber optic sensors , where the measured value is not as represented typically by an electrical quantity or transferred, but by an optical, for data acquisition in hard to reach areas such as dams or under extreme conditions such as in steel mills or magnetic resonance imaging . There are two classes of fiber optic sensors:

- extrinsic : Here the glass fiber only serves as a transmitter for the measured variable recorded by the sensor, which the sensor must provide as an optical signal. Examples are glass fiber pyrometers , fiber optic temperature probes or optical microphones ( glass fiber sound transducers ).

- intrinsic : Here the glass fiber serves directly as a measuring sensor and is therefore both a sensor and a cable. Examples are fiber-optic pressure sensors , fiber-optic temperature measurement or fiber-optic gyroscopes for measuring the angular velocity .

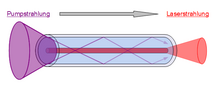

laser

For the flexible transport of laser radiation , glass fibers are used to guide the radiation to the processing point (cutting, welding, etc.) during material processing and in medicine and to the sample in measurement technology, microscopy and spectroscopy .

In laser show technology , laser light is directed from a central source via fiber optic cables to various projectors distributed throughout the room. The power here is a few hundred milliwatts up to double-digit watts.

Laser beams can not only be guided in glass fibers, they can also be generated and amplified in them. So find z. B. Fiber lasers and erbium-doped fiber amplifiers Use in the telecommunications sector. Due to the good efficiency of the conversion process and the good cooling through the large surface of the fiber as well as the very high beam quality, fiber lasers with high power are used in material processing and medicine.

Use of mechanical properties

| Typical properties of glass fibers | |

|---|---|

| density | 2.45 ... 2.58 g / cm³ |

| Filament diameter | 5… 24 µm |

| tensile strenght | 1.8… 5 GPa (kN / mm²) |

| Tensile modulus | 70… 90 GPa |

| Elongation at break | <5% |

For mechanical applications, the glass fibers are mostly in the form of rovings , nonwovens or woven fabrics . On the other hand, unidirectional fibers (only running in one direction) are used for profiles; For example, sports arrows for archery , sticks for insulation or z. B. in some umbrellas made of fiberglass-reinforced plastic.

Since glass fibers are very sensitive to notches, they are given a so-called size during manufacture or before weaving . This size (e.g. a silane size) serves as a lubricant during weaving and is chemically removed after weaving. Then the so-called finish is applied to the glass fibers, which acts as an adhesion promoter between the glass fibers and the synthetic resin for use in fiber composite materials . Finish is also referred to as an adhesive-containing size. It can be up to two percent by mass, but is usually 0.3 to 0.8 percent.

Glass fiber reinforced plastics show only a very low tendency to creep and absorb very little moisture .

strength

As a brittle material, glass is sensitive to voltage peaks, such as those that occur at imperfections such as notches (compare how a glass cutter works ). Cracks continue throughout the body. Due to the shape of the fiber, the size of the imperfections is limited to the fiber cross-section, in contrast to the compact material, and the molecular strength of the glass can be used. The elongation at break of a single fiber can be up to 5 percent. However, they are prone to kinks and sharp edges.

The tensile and compressive strength of the glass fiber ensures a special stiffening of the plastic while maintaining a certain flexibility thanks to the high elastic elongation at break (compared to steel). The properties of glass fibers are used, for example, in the production of high-strength and light components such as sports boats, GRP profiles, GRP reinforcements or fishing rods. Tanks and pipes for highly corrosive substances are usually made of glass fiber reinforced plastic.

Typically, the mean quasi-static strength of an unreinforced E-fiber of R G = 1.8 GPa is used for the construction .

Stiffness

The modulus of elasticity of glass fibers differs only slightly from that of a compact volume of material made of glass. Unlike aramid fibers or carbon fibers , glass fibers have an amorphous structure. As with compact window glass, the molecular orientation is random. The glass fiber has isotropic mechanical properties. Glass fibers are ideally linear and elastic until they break. Your material attenuation is very low.

The rigidity of a real component made of glass fiber reinforced plastic results from the modulus of elasticity, direction and volume fraction (standard: 60%) of the glass fibers and, to a lesser extent, from the properties of the matrix material, since a much softer plastic is usually used. The modulus of elasticity of the pure glass fiber is 70 to 90 GPa, about the same as that of aluminum .

Types of reinforcing fibers

The glass from which the reinforcing fibers are made influences the properties of the composite material. Therefore, different qualities of the reinforcing fibers are available:

- E-glass (E = Electric ): aluminum borosilicate glass with less than 2% alkali oxides; is considered the standard fiber for general plastic reinforcement and for electrical applications, approx. 90% of the market, is attacked in basic and acidic environments;

- S-glass (S = Strength ): aluminum silicate glass with additions of magnesium oxide; high mechanical requirements even at high temperatures;

- R-glass (R = Resistance ): aluminum silicate glass with calcium and magnesium oxide additives, high mechanical requirements even at high temperatures;

- M-glass (M = modulus ): beryllium-containing glass; Fiber with increased stiffness (modulus of elasticity), used with the highest mechanical requirements;

- C-Glass (C = Chemical ): fiber with increased chemical resistance;

- ECR-Glass ( E-Glass Corrosion Resistant ): fiber with particularly high corrosion resistance

- D-Glass (D = Dielectric ): fiber with a low dielectric loss factor, e.g. B. the radomes of a radar station

- AR-Glass (AR = Alkaline Resistant ): A fiber developed for use in concrete that is enriched with zirconium (IV) oxide . It is largely resistant to a basic environment.

- Q-glass (Q = quartz): fiber made of quartz glass (SiO 2 ). Suitable for use at high temperatures of up to 1450 ° C

- Hollow glass fibers: Fibers (mostly E-glass) with a hollow cross-section

Note: R, S and M glass are alkali-free and have increased moisture resistance.

Use of reinforcement fibers

Glass fibers are added to concrete , where they serve as reinforcement . Glass fiber reinforced concrete is used for corrugated sheets , facade panels or lost formwork . Glass fiber is also used in the screed . In addition, fine concrete is reinforced with fiberglass textiles, which is then called textile-reinforced concrete.

Glass fibers are of great importance in glass fiber reinforced plastic (GRP) (aerospace, printed circuit boards, boats, bobsleds, etc.). In the aerospace industry, long glass fibers are mainly used to build load-bearing structures (e.g. the Schleicher ASK 21 glider ). In the automotive industry , long glass fibers are still mainly used to stiffen thermoplastic components (e.g. cladding). But there is a trend towards load-bearing components here.

In process engineering , glass fibers are mainly used in coiled tubes. Here the glass fiber is characterized by its very good media resistance and electrical insulating effect.

In electrical engineering , glass fibers are used as reinforcement fibers in circuit boards or in electromagnetically transparent claddings ( radomes ). The High Voltage Technology uses high strength and insulating properties of the fibers in insulators .

Fiberglass erasers are used for manual technical drawing on drawing film and for cleaning .

Occupational safety in textile glass weaving mills

Textile glass fibers are processed in textile glass weaving mills. A distinction is made between glass filaments and glass staple fibers. The glass filaments used in textile glass weaving do not fall under the geometry criteria of the WHO fibers classified in the Technical Rule for Hazardous Substances (TRGS) 905 . However, textile glass filaments can break or shatter during processing into particles that correspond to WHO fibers. The BG / BGIA recommendations provide practical advice on how the state of the art can be achieved through protective measures in textile glass weaving mills. When processing glass filaments, there is no occupational exposure limit for fibers.

See also

literature

- Gerhard Neckermann, Hans Wessels: The glass industry - a picture of the industry. Duncker & Humblot, Berlin 1987, ISBN 3-428-06216-7 , p. 72 ff.

- Peter H. Selden (Ed.): Glass fiber reinforced plastics. Springer Verlag, Berlin / Heidelberg 1967.

- Alfred Hummel, Josef Sittel, Kurt Charisius, Fridel Oberlies, Deodata Krüger, Hans Lenhard, Martin Herrmann, Wolfgang Dohmöhl, Lothar Krüger: Recent studies on building materials and components. Springer Verlag, Berlin / Heidelberg 1942, pp. 25-27.

Web links

- Artificial mineral fibers. UmweltWissen - Bavarian State Office for the Environment (PDF; 595 kB)

- Fiberglass - Systems Glass fiber reinforced plastic pipe systems (accessed January 4, 2018)

- Novel glass fibers with innovative coatings for belt applications (accessed January 4, 2018)

- For the assessment of AR glass fibers in an alkaline environment (accessed on January 4, 2018)

Individual evidence

- ↑ Fedor Mitschke: Glass fibers. Physics and Technology, Spectrum Academic Publishing House, 2005, ISBN 978-3-8274-1629-2 .

- ^ Peter Grübl, Helmut Weigler, Sieghart Karl: Beton. Types, production and properties, Verlag Ernst & Sohn, Munich 2001, ISBN 978-3-433-01340-3 , p. 622 ff.

- ↑ Fiber-reinforced polymers ( Memento of the original from January 4, 2018 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF, accessed January 4, 2018).

- ↑ a b Axel Donges: Optical fibers - physical principles and applications netzwerk-lernen.de (PDF, accessed on January 4, 2018).

- ↑ Trudi Gerster: How angel hair got on the Christmas tree. In: Christmas stories. Buchverlag Basler Zeitung, ISBN 3-85815-094-0 .

- ↑ a b Ginger Gardiner: The making of glass fiber. compositesworld.com. Retrieved Jan 6, 2018.

- ^ A b Karen Mason: Sizing Up Fiber Sizings compositesworld.com, accessed on Jan 6, 2018

- ↑ Erwin Böhmer, Dietmar Ehrhardt, Wolfgang Oberschelp: Elements of applied electronics. Compendium for training and work, Vieweg + Teubner, ISBN 978-3-8348-0543-0 , p. 282.

- ^ Andres Keller: Broadband cables and access networks. Technical principles and standards. Springer-Verlag, Berlin / Heidelberg 2011, ISBN 978-3-642-17631-9 , pp. 73, 82, 141-144, 157, 173, 181, 257, 268.

- ↑ Erik Theiss: lighting technology. New technologies for indoor and outdoor lighting, Oldenbourg R. Verlag GmbH, Munich 2000, ISBN 3-486-27013-3 , pp. 84–86.

- ↑ Helmut Naumann, G. Schröder, Martin Löffler-Mang: Handbook components of optics. Basics - Materials - Devices - Measurement technology, 7th edition, Carl Hanser Verlag, Munich 2014, ISBN 978-3-446-42625-2 , pp. 532-536.

- ^ Dieter Bäuerle: Laser. Basics and applications in photonics, technology, medicine and art, Wiley-VCH Verlag, Weinheim 2009, ISBN 978-3-527-40803-0 , pp. 87-94, 110, 161.

- ↑ Glass roving fabric (PDF, accessed on January 4, 2018).

- ^ A b Manfred Flemming, Gerhard Ziegmann, Siegfried Roth: Fiber composite construction methods . Fibers and matrices, Springer Verlag, Berlin / Heidelberg 1995, ISBN 978-3-642-63352-2 , pp. 51-66.

- ↑ Chokri Cherif (Ed.): Textile materials for lightweight construction - Techniques - Process - Materials - Properties. Springer-Verlag, Berlin / Heidelberg 2011, ISBN 978-3-642-17991-4 , p. 68.

- ↑ Monika Helm: Steel fiber reinforced concrete in practice. Manufacturing - processing - monitoring. Verlag Bau + Technik, Düsseldorf 2014, ISBN 978-3-7640-0560-3 , pp. 28–35.

- ^ Roman Teschner: Glass fibers. Springer Verlag, Berlin / Heidelberg 2013, ISBN 978-3-642-38328-1 .

- ↑ Joachim Lenz (Ed.): Pipelines - a neverending story? Vulkan Verlag, Essen 2003, ISBN 978-3-8027-5389-3 , p. 321 ff.

- ↑ Serope Kalpakjian, Steven R. Schmid, Ewald Werner: materials technology. Manufacturing - processing - manufacturing. 5th updated edition, Pearson Education, Munich 2011, ISBN 978-3-86894-006-0 , pp. 1111-1115.

- ^ Association of German Secretaries V. (BDS) (Ed.): Departure into the office future. Special edition of the magazine SEKRETARIAT, Springer Fachmedien, Wiesbaden 1982, ISBN 978-3-409-91021-7 , p. 94.

- ^ Beuth Verlag GmbH: DIN 61850: 1976-05: Textile glass and processing aids; Terms. Accessed January 2, 2020 .

- ↑ German statutory accident insurance e. V. (DGUV): DGUV Information 213-721 - BG / BGIA recommendations for risk assessment according to the Hazardous Substances Ordinance - Textile Glass Weaving. Accessed January 2, 2020 .