Arrow (bullet)

An arrow (medium high German Phil , borrowed from latin PILUM "javelin, spear") is the litter floor of a sheet or the floor of a blow pipe . It is a form of long-range or ranged weapon. It usually consists of an arrowhead , a cylindrical arrow shaft and at the other end fletching and a nock to hold the bowstring or throwing device. Bow arrows have been around since the end of the Paleolithic ( Ahrensburg culture) known as archaeological finds. The forerunners of the bow arrow were thin and long spears that were thrown with the spear thrower. In contrast, the projectiles of the crossbow are usually referred to as bolts , whereby the long projectiles of modern hunting and field crossbows are increasingly also referred to as arrows. Today arrows are mainly used in sport archery and for bow hunting .

history

The arrow is older than the bow, as the principle of acceleration through a technical aid was already used in the Upper Palaeolithic spear thrower . With its limbs, the bow can store more energy and convert it into kinetic energy than a hurling movement of the human arm. Simple wooden bows (so-called selfbows ) were an invention of the Magdalenian . The production of the bow requires appropriate wood resources, while spear throwers and corresponding darts can also be made of inferior wood. With the Aleutians , bow and slingshot (special form of the spear thrower) existed side by side as hunting weapons until the beginning of the 20th century.

Arrows were also used as projectiles in combat and war. They could be shot with a bow or hurled with a catapult . Sometimes - as with the Falarika - combustible material was used to ignite it before hurling it and to achieve a higher combat effect.

Modern bows use additional requirements, the "overdraw", in order to be able to shoot arrows that are shorter than the archer's draw length . A lighter arrow reaches a higher speed.

The projectile of a blowpipe is also called an arrow , although it is much smaller and lighter. Primitive peoples use it as a poison arrow, mostly for hunting. Nowadays the blowpipe is also used by veterinarians to anesthetize animals or to give them medication. In addition, blowguns are used as sports equipment around the world. In terms of health, the positive increase in lung volume with regular training was recognized, which is why blowgun sport is even used therapeutically. Blowguns have only been known in Europe since the Middle Ages. They developed prehistorically in East Asia, North, South and Central America. The term arrow was transferred to their projectiles, in English these are called darts and not arrows "bow arrows".

construction

The arrow is basically a straight rod with a tip at the front end and natural feathers at the rear end or artificial feathers attached as fletching for stabilization. At the rear is the cam, a notch that ensures contact with the bowstring .

Arrow weights are traditionally given in grain , one grain corresponds to 0.0648 grams . Today's typical arrows are about a few hundred to about 500 grains, but old English war arrows could also weigh more than 800 grains, i.e. more than 52 grams.

shaft

The shaft shape can be conical (tapered) , elongated barrel-shaped (barrel taper) or cylindrical (standard). An important property of the shaft is its flexural rigidity, its spine (see below), which must be matched to bow and archer for the best flight characteristics and thus accuracy. Ideally, an arrow shaft is only slightly longer than the archer's extension.

Wooden stocks

The traditional shaft material is wood . In the European Neolithic , arrows were preferably made from the saplings of the woolly snowball . Arrow shaft straighteners made of stone, bone or antler have been used in pairs since the end of the last glacial period , also made of sandstone , as in the Mesolithic Ahrensburg culture (Buxtehude-Immenbeck), in the neolithic ceramic band - and the menhir culture . In the Middle Ages was ash a popular shaft material.

Today, Lawson's false cypress ( Chamaecyparis lawsoniana , in America Port Orford Cedar, also just “cedar” for short) or the giant arborvitae ( Thuja plicata , Western Red Cedar) are used. But also spruce shafts (lighter than cedar) and pine shafts are finding more and more followers because they are relatively light - today one no longer uses such high pulling weights - and are made from local wood and inexpensively.

Shanks made from other materials

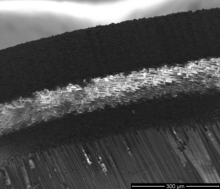

Modern arrow shafts are made from materials like aluminum , carbon fiber, or combinations of both. The shafts are thin tubes whose flexural strength is determined by the material, the wall thickness and the design.

In Asia , arrows are also made from bamboo shoots (for example the traditional arrow material in Kyūdō or the Beder in Java). The previously irregularly shaped, 2-year-old stalks of the arrow bamboo are straightened in several steps while heating over an open fire and ground with stones. With bamboo arrows, thread windings are attached to the ends in order to prevent the shaft end from splitting due to the inserted shaft of the arrowhead when firing. Due to the natural cavity and its tensile strength of the fiber composite, which is outstanding for a natural material, a bamboo shaft achieves higher strength values than a solid wood shaft ( flexural strength ) with the same mass .

A typical arrow shaft is about 1 ⁄ 3 inch thick. Standard thicknesses are 5 ⁄ 16 ″ (7.9 mm), 11 ⁄ 32 ″ (8.7 mm) and 23 ⁄ 64 ″ (9.1 mm).

Spine value

The so-called spine value , or spine for short , is a measure of the bending stiffness of the arrow and is traditionally given in pounds sterling , in such a way that the value roughly corresponds to the tensile strength of an English longbow for which the arrow would be suitable. The ideal spine value also has an individual component for each shooter. The adaptation of the spine to the bow and archer is especially important for traditional archer, because the string moves exactly towards the bow when firing, but the arrow has to wrap around the bow ( Archer's Paradox ). A wrong spine leads to poor flight characteristics, for example to a restless flight, a lateral deviation from the straight flight path or the undesired hitting of the arrow shaft on the bow - accuracy suffers. Ideally, the oscillations of the arrow shaft should be dampened after a few 10 meters of flight.

The spine is determined by placing the arrow on two supports with a defined distance and attaching or placing a corresponding weight in the middle of the arrow. The principle is the experimental determination of the flexural modulus in the 3-point bending test at a normalized distance interpolation point from the original 26 inches and a central loading weight from the original 2 pounds ( lbs ), or about 908 g. The deflection of the arrow shaft from the horizontal at the lowest point on the underside is measured in 1/1000 of an inch and referred to as the static spine value (in contrast to the dynamic spine value ) and, depending on the shaft type, converted into the sports technical unit used. The smaller the value, the stiffer the arrow and the larger the converted value in pounds for the traditional specification, which relates to the tensile strength of the bow (AMO standard measurement method, also to be found as ATA standard, see Archery Trade Association ).

In Easton's proprietary ASTM standard (also known as the "Easton Standard"), the support span is 28 inches and the weight is 1.94 pounds (880 g).

- AMO Spine

- at 26 ″ span, 2 lbs center load.

- ASTM Spine

- at 28 ″ span, 1.94 lbs center load.

- Conversion of deflection

- Spine in pounds of draw weight

To measure the spines comes a spine tester used.

For wooden stocks, the AMO standard is usually measured and specified. Wooden shafts are delivered either in groups of 5 lbs (41–45 #, 46–50 #, etc.) or, for an additional charge, per shaft “handspined” with a specified accuracy, for example to an accuracy of ± 1 lbs. In the case of hand-spun shafts, the spine value is usually noted in handwriting on each shaft, e.g. B. 50 # , pronounced "fifty spine" or "spine fifty".

The following table facilitates the conversion between AMO standard and spine in pounds (according to the formula: AMO spine = 26000 / tensile force of the bow).

| AMO spine in 1/1000 inch | Spine in pounds |

|---|---|

| 1300 | 20th |

| 1040 | 25th |

| 867 | 30th |

| 743 | 35 |

| 650 | 40 |

| 578 | 45 |

| 520 | 50 |

| 473 | 55 |

| 433 | 60 |

| 400 | 65 |

| 371 | 70 |

| 347 | 75 |

In general, the stronger the bow and the larger the extension, the stiffer the appropriate arrow must be. However, modern bows usually have a "shot window", a recess in the body of the bow. This enables the arrow to rest closer to the central axis of the bow , as a result of which the required amplitude of the bow of the arrow in the winding around the bow body is reduced. Some bows also have a structure that enables the arrow to be centered in the ejection plane of the bowstring, which means that the arrow is shot in a straight line - there is no need to "wind around" the body of the bow.

If the arrow is too soft, it can break splintering when released and cause severe injuries, especially to the bow hand, sometimes in the face and neck area.

Cresting

The decorating and painting of the arrow shaft for individual identification with varnish is called "cresting". The arrow is embellished, more unmistakable and clearly visible due to the striking colors. In order to speed up the time-consuming work process, the idea of using printed foils, the so-called "arrowwraps", came up.

Arrowwraps

Under this name, a printed high-performance film is offered that can be stuck around the arrow shaft to improve the properties. The weather and UV resistance of the film including the color print is specified as at least 7 years with constant outdoor use in all conditions between −45 and +95 ° C. The film is about 3/100 mm thick and high demands are made on its adhesion. The adhesive bond of the “wrap” can be loosened by immersing it in boiling water.

top

1 u. 2 - Beginner arrows made of wood with sheet metal point,

3 - cedar wood shaft with field point,

4 - field point with "insert" on fiberglass

shaft, 5 - field point on aluminum shaft,

6, 7, 8, 9, 13, 14 - "bullet" points,

7 u . 11 - different disc tip "insert" for aluminum / carbon arrow shafts ,

10, 11, 12 - cone tip "insert",

11, 13, 14 - carbon shafts with different diameters,

15 - brass point in front of fiberglass

shaft , 16 - a destroyed aluminum arrow shaft after a stone

hit , 17 - a “blunt” point

The arrowhead is generally made of metal . But points made of flint , slate and bones are also known from prehistoric times . In principle one can also sharpen the wooden shaft and harden it in the fire , but since such arrows are poorly preserved, nothing is known about the actual prehistoric use of sharpened arrows.

The tip can either be placed as a sleeve on a conically shaped shaft, or a mandrel on the tip is placed in a hole or notch in the shaft. The tips are attached by gluing or screwing on. Medieval lace was often additionally secured with a thread winding .

Today's tips for sports are mostly simple, twisted metal tips that are put on as a sleeve and that are designed to damage the target as little as possible and to make it easier to draw the arrow. Modern broadheads either have an additional blade with sharpened edges (“broadhead”) or blunt, extended tips (“blunts”) to stun the prey .

In the past, there were numerous other point shapes, especially for war purposes. Typical was the Ahl point ("bodkin" point), which, thanks to its long, narrow wedge shape, could penetrate the riveted rings of the chain mail and thus burst them open . It was also very easy to forge . The tip of an incendiary arrow had a metal cage just behind the actual tip in which combustible material could be placed, so that the heat acted directly on the target but did not damage the shaft prematurely. For the targeted killing of horses that were less often protected by armor than their riders, particularly wide arrowheads were used.

Paulus of Aegina from the school of Alexandria wrote a treatise on arrow wounds in the 6th century. He distinguished between different shapes of arrowheads. So there were arrows that were barbed, which are directed against the direction of fire. They make it difficult or impossible to pull them out (extraction “per expulsionem”) and he advised to push them through if possible and pull them out on the other side (extraction “per impulsionem”). There were also barbs oriented in the direction of the weft. This could not be pushed through, but pulled out. There were also points whose barbs were aligned both with and against the direction of fire and whose shape was reminiscent of a lightning bolt. Such spikes made both types of removal difficult. He also described arrows whose barbs have joints and only spread when they are pulled out. He also described that some arrowheads are attached to the shaft with a spike and others with a small tube. Aulus Cornelius Celsus describes the "Spoon of Diocles" as a surgical instrument to cover or break off the barbs of arrowheads that are otherwise not removable. If the arrow could not be removed by pulling or pushing it through, for example because the tip was stuck firmly in the bone, various "solvents" applied to the wound and arrow shaft were used to soften the shaft or the connection between the tip and shaft. The shaft was pulled, the tip remained in the body. Often this method only consisted of an intentionally moist dressing of the wound in order to achieve the same effect by necrotizing the tissue along the shaft and increasing wound secretion. The arrow or shaft should rot out of the body for days or weeks. Most of those arrow wounded did not survive this treatment.

The so-called “tendon cutters” today were tips that ended in a wide sheet that ended openly in the shape of a crescent moon and the front side of which was ground as a cutting edge. The actual use of such tips in the war is unclear. In particular, whether these were actually used against ropes is controversial. Modern experiments, however, have shown an enormous potential for injury from soft tissue hits. Use in hunting is also conceivable.

Poisoned arrowheads were historically intended on the one hand for hunting, for example to prevent the prey from escaping in impassable jungle terrain or to hunt down large prey with weak bows. On the other hand, they were used for war purposes in order to increase the effect of not immediately fatal hits. In Europe and Japan, however, the use of poison arrows was frowned upon as "unknightly" (which did not rule out the occasional use). In South America, for example, curare and the skin secretion of poison dart frogs were used as poisons , in Europe, for example, extracts of monkshood . The rumor that the English were poisoning their arrows during the Hundred Years War in France can be explained. U. can be attributed to the fact that the English shooters stuck their arrows into the ground in order to be ready for fast shooting. B. spores from tetanus and gas fire pathogens could get into the wounds caused. The medical field of toxicology has its origins in the treatment of poisoned arrow wounds and the research into arrow poisons. Greek: Toxikon comes from Toxon (τόξον "arrow") and means "pillar".

In the field of sports, especially in roving, i.e. archery at objects in the great outdoors, blunt tips, i.e. judo points or rubber blunts, are also used today. Unsharpened arrows usually do not get stuck in wooden stumps and do not bury themselves so deeply into the earth if they are missed, so that they are easier to find again.

Fletching

In the course of history, a wide variety of fletching was used for arrows, with medieval archers favoring goose feathers. The main purpose of the fletching is to place the aerodynamic pressure point far enough behind the center of gravity. Only then can the arrow follow the parabola stably. If the springs are placed at an angle to the longitudinal axis of the arrow, it rotates. With certain arrow shapes, this can stabilize the flight path.

2–4 springs were found on historical arrows, 6 springs are also used on modern "Flu-Flu" arrows (for short distances).

Today (apart from self-found or plucked feathers from geese, seagulls or crows), three types of feathers are generally used:

Turkey feather

These are available in different lengths (3 to 5.5 inches or full length ), shapes (parabolic, shield, double parabolic, double shield, etc.) and colors (natural, signal yellow), which are mainly used in traditional archery and field tournaments or 3D tournaments become. (3D tournaments: three-dimensional targets, mostly animal dummies or fantasy creatures, made of plastic are shot with a bow and arrow. Full-length feathers are cut into a desired shape by hand or by means of a spring punch or, uncut, a Flu-Flu arrow is feathered with it.

There are left and right coiled feathers, a name for the natural direction of curvature of a feather, depending on whether it comes from the bird's right or left wing. A Sagittarius usually uses only feathers in one direction for a set of arrows (a dozen or half a dozen). The direction of the coil of the spring creates the direction of rotation of the arrow in flight. Through rotation, the arrow with its angular momentum gains an additional flight-stabilizing moment of inertia against the effects of forces perpendicular to the flight path. This also dampens the transverse vibration of the shaft more quickly. In order to generate a stronger rotation, the springs are often attached at a slight angle, in principle a ship's propeller. Because creating and maintaining required of rotational energy, this is rotational energy from the kinetic energy of the arrow in flight direction lost - the greater the rotation, the more stable the flight, the slower the arrow.

Natural feathers have the disadvantage that when wet they soak up and lie against the shaft. This results in poorer stabilization of the arrow. According to the manufacturer, this can be counteracted with various commercially available means. There are powders or sprays for impregnation. The big advantage of natural feathers at tournaments in the field is as follows: If the fletching of an arrow hits an obstacle, for example a tree branch, the arrow is not deflected as much as a plastic feathered one. The same advantage also comes into play when shooting. When the arrow leaves the bow, the feathers brush against the bow window, the rest or the back of the hand, depending on the shot. Real feathers then straighten up within a few milliseconds and optimally stabilize the arrow flight. With the same feather area, natural feathers are lighter than other fletching materials.

Eagle feather

In kyūdō , eagle feathers are considered to be of the best quality, as they also withstand the impact of the feather on stone. For reasons of species protection, eagle feathers are very expensive; a single arrow can cost several hundred euros. Today, turkey feathers are mostly used for training purposes.

The fletching on kyudo arrows is longer than on European arrows and is straight. The rotation of the arrow is generated by the “wing” profile of the spring, similar to the lift of aircraft. One arrow with the right feathers ("Haya") and one arrow with the left feathers ("Otoya") are fired per round. This is historically justified by the fact that the second arrow (for a marksman) is the first due to the slightly different flight characteristics Arrow does not hit the nock and thus destroyed. In practice, however, both wings of the eagle will have been used for practical reasons.

Plastic spring

Is the most common type of spring that comes in different lengths and stiffnesses. The sporty elite use so-called spin wings for long distances (outdoors up to 90 meters). They are also made of plastic and are screwed in parallel to the arrow axis so that they rotate even faster.

FOB vanes

For "compound" bow arrows there is a new type of fletching that has nothing to do with feathers. FOB ("Fletching Only Better") is a three-bladed propeller with a jacket ring, which is placed as a plastic part on the arrow shaft and causes a faster rotation (see also turbo cam ).

Flu-Flu fletching

A flu-flu arrow refers to an arrow for a bow that is specially designed for short distances. So it is u. a. especially when shooting at targets in flight or at high altitude, for example in trees. The Flu-Flu does not fly far and is therefore easier to find again if the target is missed - also because of its conspicuous fletching.

A flu-flu arrow is designed in such a way that it has a relatively high air resistance after a short flight time. Initially, immediately after leaving the bow, the feathers put themselves on, after a short flight they straighten up, due to the then oversized area the arrow suddenly slows down and sometimes falls almost vertically from the sky. This is achieved through a special fletching. Possible techniques here are a spiral winding of one or two full-length feathers around the shaft without cutting the height of the flag - the appearance of the arrow is reminiscent of a toilet brush - or attaching particularly large or bushy feathers or using four to six feathers instead of the usual ones three.

Nock

To ensure that the arrow sits securely on the bowstring, the rear end of the arrow has a nock. This is so narrow that the arrow will hold on to the string by itself, but still so loose that the arrow can be easily released when fired without being slowed down.

1 - wooden shaft,

3, 4, 10, 11 - aluminum shaft,

5 u. 6 - fiberglass

shaft , 7 - carbon shaft Fletching

with visible twist : 1 - clockwise, 3 - counterclockwise

Selfnock

Originally the nock consisted of a slot sawn or ground into the end of the shaft. This must be formed perpendicular to the cross-section of the wood grain to prevent the shaft from splitting due to the pressure of the tendon. For additional stability, a circumferential wrap made of a thread can be attached below the nock behind the fletching. To further strengthen the nock, an inlay made of hard wood, horn or bone is sometimes glued in, into which the nock slot is then sawn. Today there are special tools for sawing or grinding in the cam.

Glued-on nock

The modern arrows have a plastic nock that is attached to the shaft and glued in place. Various adhesives are used , for example superglue , two-component glue or hot glue . If the nock cannot be glued to an existing cone, an “insert” adapter is used for arrow shaft tubes, which is often referred to as “bushing” to delimit inserts for screwable arrowheads. Often the nock is simply attached and possibly adapted to the individual shaft with a little thread in order to later enable easy replacement or rotation of the nock. For wooden shafts, there are special sharpeners to shape the matching cone to the inner cone of the glue block at the end of the shaft. Similar to the self-nock, the slot of the nock on the wooden shaft is aligned perpendicular to the course of the cross-sectional grain.

Turbo-Nock

Previous nocks were provided with an axial cutout or slot. This innovation has the same cutout, but it is provided with a twist. After being shot, the arrow is brought into a rotary motion by this new "nock twist" on the bowstring, which can reach between 4,000 and 9,000 revolutions per minute. The rotational energy supplied to the rotation is lost from the kinetic energy of the arrow in the direction of flight, the arrow flies more stable, but is slower than without or with less rotation. The Turbo-Nock can be manufactured individually or in one piece with very short (plastic) springs. This is attached to the (carbon) arrow shaft tube and glued in place (see also FOB-Vanes ).

Luminous nock

So that the flight of the arrow can be followed well from the point of view of the shooter even in low light, and game or a lost arrow can be found more easily, there are nocks that are equipped with color LEDs and (lithium) batteries. In one design (Lumenok), the small, long-cylindrical battery with a coaxial pin contact and an O-ring in the housing groove is inserted into the cam from the front while rotating. This is inserted into the end of the arrow tube and pulled out a little to turn off the light. When fired, it is pushed back in under the pressure of the tendons. This closes the circuit and the LED lights up.

See also

literature

- Bruno Fridrikhovich Adler: The North Asian Arrow , A Contribution to Knowledge of the Anthropogeography of the Asian North, Volumes 13-14, Diss., EJ Brill, Leipzig 1901.

- Charles E. Grayson et al. a .: bow, arrows, quiver. The Charles E. Grayson Collection . Verlag Angelika Hörnig, Ludwigshafen 2010, ISBN 978-3-938921-17-3 .

- Volkmar Hübschmann (Ed.): Archery - equipment and accessories made by yourself. 2nd edition, Verlag Angelika Hörnig , Ludwigshafen 2007, ISBN 978-3-938921-03-6 .

- Hubert Sudhues: wound ballistics for arrow injuries. Dissertation. With a comprehensive introduction to the basics of archery. Institute for Forensic Medicine, Westfälische Wilhelms-Universität Münster, 2004.

Web links

- Daniel Yononindo: Ultra Slow Motion Video - Archer's Paradox. Different spine values until the arrow breaks. Video (2:54 min.). In: youtube.com. Retrieved August 16, 2016.

- Archer's multitool. Various calculators and converters (spine, front of center, fps ↔ km / h, etc.). Retrieved August 16, 2016.

- Making a stone-tipped arrow. ( Memento from January 1, 2009 on the Internet Archive ) Video.

- Instructions for building a four-spring Flu-Flu arrow ( Memento from January 22, 2013 in the web archive archive.today )

Individual evidence

-

↑ Photo: Injury to bow hand (right), broken carbon arrow when loosening. In: www.pirate4x4.com ,

photo: injury to bow hand (left), broken carbon arrow when loosening. In: discussions.texasbowhunter.com . Retrieved August 15, 2016. - ^ A b c d Hubert Sudhues: Wound ballistics in arrow injuries. Dissertation. Institute for Forensic Medicine, Westfälische Wilhelms-Universität Münster , 2004. (PDF 2.7 MB). Retrieved August 15, 2016.

- ^ Spoon of Diocles, at Medicus-Romanus.de

- ↑ G. Embleton, J. Howe: Mercenary life in the Middle Ages. Motorbuch Verlag, ISBN 3-613-02678-3 .

- ↑ http://www.lumenok.net/ Lumenok, Burt Coyote, Lighted Arrow Nock, accessed August 20, 2012

![{\ displaystyle {Spine} _ {AMO} = {Deflection} \ left [{\ tfrac {1} {1000}} '' \ right] \ quad}](https://wikimedia.org/api/rest_v1/media/math/render/svg/28876c44d030ead242abc8de4b317d50f076d066)

![{\ displaystyle {Spine} _ {ASTM} = {Deflection} \ left [{\ tfrac {1} {1000}} '' \ right] \ quad}](https://wikimedia.org/api/rest_v1/media/math/render/svg/88877df2204588f6de49856dbb5d511466189d0a)

![{\ displaystyle {\ begin {aligned} {Spine} \ \ left [{lbs}, {\ #} \ right] & = {\ frac {26 '' \ cdot 1000} {{Spine} _ {AMO}}} = {\ frac {26 '' \ cdot 1000} {0 {,} 825 \ cdot {Spine} _ {ASTM}}} \ end {aligned}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/89b518bc8cc8c4dc972262ed51e052b53bfd14a9)