blade

The blade is the main component of various tools and weapons . In the real sense, it is the entire device, with the exception of the parts that are used for holding ( handle ) or protection ( sheath ). Blade is also colloquially referred to as the cutting edge , the sharpened part of the blade.

Parts and function

profile

Apart from unusual, material or randomly free and special shapes, a distinction is mainly made between three- and four-edged, elliptical, full and three-quarter round blade cross-sections. Three- and four-sided engraving blades like swords or stylet may have partially or on all sides sharpened or unsharpened edge. Whether and how a sharpened edge can be designed as a functional cutting edge is primarily determined by the blade profile. Elliptical and diamond-shaped blades such as swords or daggers can be single or double-edged. Due to their shape, full round stabbing blades have no cutting edge.

Leaf, back, neck

In the case of wide blades, the blade refers to the part that carries the cutting edge. The edge opposite the cutting edge is called the back of the blade . The weaker half that lies against the tip is called blade weakness , the other blade strength .

The piece between the sheet and the booklet (handle) is commonly referred to as the neck . The extension going through the booklet is called Erl or Angel . In the case of special fields of blade production, however, other terms are also used.

Cutting edge

The geometry of the cutting edge is decisive for the function of the cutting edge (the term is widespread in manufacturing technology, but also applies to weapons analogously.)

The blade gets its sharpness by grinding ( sharpening ). Cutting edge or blade sharpness describes the sharpened part of the blade and also its cutting properties. The cutting edge is tapered to a point and is made with special whetstones , with particularly good cutting edges polished with leather ( strop ).

Tools for cutting woodworking are also given a hollow grind . Exclusively stabbing weapons and tools (like the awl ) are only sharpened. Sharpening due to the profile does not count as cutting in the technical sense.

materials

The blade is mostly made of metal , nowadays almost always made of knife steel with a few exceptions made of ceramic , titanium alloys or other non-ferrous alloys (e.g. Talonite). Even more rarely, plastics are used that have comparatively little edge retention, but are not detected by metal detectors .

For particularly noble or stressed blades, two or more layers of steel are used, which consist of layers of tough iron , spring steel or tool steel . With famous blades, the patterns that are created on the cutting edge during manufacture can be a distinctive distinguishing feature ( Damascus steel or hardening pattern ).

Blades for medical use are mostly made of hardenable, corrosion-resistant stainless steels. Particularly high-quality scalpels for microsurgery are also made from natural or artificial diamond. These diamond blades are considered to be the sharpest blades in the world.

Areas of application

Tool blades

Blades are necessary in numerous separating processes. There are knives , scissors , axes , gouges , etc.

A distinction is made according to the design, for example:

Or after use:

- razor blade

- Surgical blade (scalpel), surgical knife

- Microtome Blade: Ultra-thin biological sections for clinical diagnostics.

- Industrial blade - industrial knife: Use of blades / knives in industrial production processes for separating / cutting fabrics / materials (foils, paper, etc.)

- Planer knife

- Knife blades (hunting, kitchen and other knives), see main article Knives

Blades on cutting, thrusting and throwing weapons

Blades of cutting weapons must have a wedge shape. The thinner the back and the sharper the cutting edge, the easier it is to penetrate and the less force is required. Penetration is further facilitated by making the blade curved because the penetrating part is then smaller.

Blades of stabbing weapons must be completely straight and have their center line in the direction of impact. Any bend would break the impact force and cause missed hits. A conical or pyramidal tip is used for easy and safe penetration. The cross-section of the stabbing blade can be circular, angular or oval.

Famous blades came from Solingen ( Solingen blade ), Toledo ( Toledo blade ) and Damascus ( Damascus blade ).

Japanese blades, especially katanas , are known to pay particular attention to the blade shape and the layered structure . Examples of different blade structures can be seen in the illustration opposite.

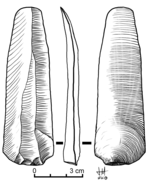

Flint blades

In archeology , blade refers to a cut , usually made of silicate rock , which is at least twice as long as it is wide, has a triangular or trapezoidal cross-section and a regular edge. Blades appear at the end of the Middle Paleolithic , probably first in the Middle East.

Cleaver blades can also be made of rock. For the stock see stock (prehistory and early history) .

Web links

Individual evidence

- ↑ Joachim Hahn : Recognizing and determining stone and bone artifacts. Introduction to artifact morphology. Institute for Prehistory, Tübingen 1991, ISBN 3-921618-31-2 ( Archaeologica Venatoria 10).

- ↑ Anthony E. Marks (Ed.): Prehistory and paleoenvironments in the central Negev, Israel. 2 volumes. SMU Press Dallas TX 1976-1977.