Knife steel

Knife steel is a steel material suitable for the blades of knives .

properties

The properties of the material steel can manufacturing process and heat treatment can be specifically tailored to a specific purpose. For knife blades , cutting and usage properties such as edge retention , cutting ability and sharpenability are important, which can be achieved with carbon steels in particular , but also with low and high-alloy stainless steels .

Knife steel requires the following properties:

- Hardenability: The blade material should have a hardness of at least about 55 HRC . The ideal value for blades with fine cutting edges without shock stress is around 60-62HRC. For kitchen or hunting knives, an HRC of 57–60 is recommended because of the easier regrinding and the lower brittleness ( risk of breakage ) of the material. A steel from 0.22% carbon can be hardened, while significant amounts of nickel prevent hardening.

- The strength is usually favored by a fine structure . This means both the hardening structure martensite and the fine grain of the carbides usually present in these materials . The fine grain is the basis for toughness and elasticity and thus fundamental for the sharpness that can be achieved .

- The corrosion resistance is of concern when the blades in the dishwasher cleaned or longer time to be exposed to moisture. To do this, steels are used that are alloyed with chrome , nickel and molybdenum . After successful heat treatment, at least 13% chromium should be dissolved in the basic mass of the steel. The disadvantage of adding chromium, but also molybdenum in such considerable amounts, is that the achievable hardness of the steel matrix is reduced and the structure is sometimes very coarser, which leads to a reduction in toughness.

In principle, materials with a fine structure and high hardness such as low-alloy carbon steels ( tool steels for cold work) are particularly suitable for achieving good cutting properties and high sharpness. Blades made of rusting carbon steels are sufficiently hard in the steel matrix, sufficiently tough when properly heat treated , and the cutting edges can be finely ground. In these steel grades in microcrystalline structure carbides contained are particularly fine-grained (see sharpness ) can be ground so that the cutting of thin and in more acute angle. However, very fine cutting edges are sensitive and can break out. Experienced cooks therefore use different knives for numerous different cutting tasks.

German knife steel

Typical stainless knife steels

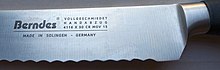

A typical knife steel of the German blade industry is X46Cr13 (material number 1.4034, American designation AISI 420 C, so-called "Swedish steel "). It is a martensitic chromium steel and contains 0.46% carbon and 13% chromium . As a carbide-forming agent , chromium ensures that the steel hardens and does not rust, even with mild quenching . The material is mostly used in the blade industry with a hardness of 50 to 56 HRC. It is often used in Solingen in the manufacture of knives.

The material X45CrMoV15 or X50CrMoV15 (material number 1.4116, a martensitic stainless steel) is even more common. It contains 0.45 to 0.55% carbon , 14 to 15% chromium , 0.5% to 0.8% molybdenum and 0.1% to 0.2% vanadium . The purpose of adding molybdenum to the alloy is to increase the pitting corrosion and thus the dishwasher resistance of the material. The material is mostly used in the blade industry with a hardness of 50 to 56 HRC.

Due to their high chromium content, both alloys are considered to be corrosion-resistant ( rust-free ) with appropriate heat treatment . They represent a good compromise to suitability for everyday use due to good corrosion resistance, sufficient hardness, good sharpenability and good toughness. Theoretically, these steels can still hold cutting angles of 20 ° to 30 °. The industry values the good availability at low cost and the easy processability.

Pressure embroidered cold work steel

Martensitic stainless steels (e.g. 1.4116) can corrode if there is a high concentration of chlorine ions in drinking water and if strong cleaning agents are used. Compression nitrogen alloyed steels based on X C + N CrMo 15 have a higher corrosion resistance with high hardness; A high level of toughness can be achieved even with high hardnesses. A corresponding steel that can be hardened to 60 HRC is sold under the brand name " Cronidur 30 " and used as a raised knife steel (material code 1.4108; AMS 5898; X 30 CrMoN 15 1).

Japanese knife steel

Two Japanese steel names are Aogami ( 青 紙 , Japanese: blue paper steel ) and Shirogami ( 白紙 , Japanese: white paper steel ) - they are named after the color of the packaging paper. Both are not rustproof.

The Aogami -Stahl is a low alloy Japanese carbon steel . It has a carbon content of over 1% and, when properly hardened, has a hardness of 64 to 66 HRC. With correct heat treatment, this material has a structure with fine carbide and the finest martensite . This gives it the potential for very high sharpness, easy sharpening and edge retention. Due to the tungsten content, it is more wear-resistant than the Shirogami steel. Analysis of the minor components in percent : C = 1.2; Si = 0.1; Mn = 0.2; Cr = 0.3; W = 1.1; P <0.025; S <0.004. This alloy comes closest to the German alloy 1.2414 (120W4).

The Shirogami is an unalloyed Japanese carbon steel. With correct heat treatment, this material also has a structure with fine carbide and the finest martensite. It also has the potential for very high sharpness, easy sharpenability and edge retention. The hardness in use is between 63 and 65 HRC. Analysis of the minor components in percent: C = 1.1–1.2; Si = 0.1-0.2; P <0.025; S <0.004. This steel corresponds quite well to the German alloy 1.1545 (105W1)

Since both types of alloys do not contain chromium, they are naturally not corrosion-resistant, unlike the rust-resistant alloys used in the German blade industry. With appropriate heat treatment, the steels can be ground to cutting angles of 15 ° to 25 °. Despite great hardness and wear resistance, both steels can be sharpened easily.

Japanese knives are often made of two, three or more layers of steel and iron laminated in such a way that they can achieve good hardness in the cutting edge and high toughness in the overall blade . See also: Japanese Kitchen Knife (Hōchō) and Japanese Sword (Katana) .

American knife steel

An American steel that is used, among other things, for so-called "custom knives" is the powder metallurgical steel CPM S30V from Crucible Materials Corp., Syracuse , USA. This steel contains 1.45% carbon, 14% chromium , 4% vanadium and 2% molybdenum . It is a particularly high-alloy, corrosion-resistant tool steel with very good wear resistance. The hardness in use is 57–59 HRC. Due to its high content of special carbides, the material is also quite brittle. Sharpening is also difficult. Fine and particularly sharp cutting edges cannot be achieved. The cutting edge angle should be at least 40 °.

Corrosion resistance

Knife blades made of rusting carbon steel , non-corrosion-resistant (mostly magnetizable, ferritic ) knife steel can corrode if they are not always dried after use.

Cleaning in dishwashers accelerates corrosion due to the action of water at higher temperatures in connection with organic acids ( fruit acids ) from food and drink residues as well as the chemicals contained in detergents and machine dishwashing detergents . Rinse aid usually also contains citric acid or tartaric acid .

With chromium-nickel steels, corrosion usually only occurs on stress cracks or as flash rust . In addition, contact corrosion arise when chloride containing washing water is applied, where different metals are joined together (for example, when the blade and staple a knife of carbon steel made).

Corrosion reduces the sharpness of non-rustproof blades . Manufacturer of dishwashers , therefore, knives and recommend high-quality kitchen knife is not cleaned in the dishwasher, but to clean, rinse with detergent and hot water by hand to dry and when not in use with acid-free cooking oil rub. Non-waterproof handle material such as wood (including plywood), bone, horn, ivory, etc. must not be cleaned in the dishwasher anyway.

Individual evidence

- ↑ Archived copy ( Memento of the original from May 8, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. ; Retrieved June 5, 2012.

- ↑ Cronidur 30 data sheet ( Memento of the original from March 7, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , accessed June 6, 2012.

- ↑ Georg Schwedt : Chemistry in everyday life for dummies. Wiley-VCH, Weinheim 2010, ISBN 978-3-527-70318-0 .

- ↑ Commercial dishwashing & wash ware made of metal. Published by: Working Group on Commercial Dishwashing, 2007, PDF file

literature

- Claus W. Wegst, Micah Wegst: Steel key . Steel key Wegst, Marbach 2007, ISBN 978-3-922599-23-4 .

- Roman Landes: Knife Blades and Steel: Technological Consideration of Knife Edges. Wieland-Verlag, Bad Aibling 2006, ISBN 978-3-938711-04-0 .

Web links

- An overview of knife steel grades at sr71.dyndns.info, accessed on February 12, 2017.