Resin (material)

When it comes to resins, a distinction is made between natural resins and synthetic resins.

Natural resins are mixtures of solid, amorphous , non-volatile, lipophilic plant products. After natural or artificial injuries, they emerge as a viscous mass from certain plants, mainly trees. They are either dissolved in essential oil - then they are called balms . Or the resins emergefrom the plantas emulsions or suspensions in aqueous mucilage solutionswith a little essential oil - then after drying they are called gum resin . Resins are probably primarily used by plants to seal injuries and to ward off insect pests. In the case of balsams, the viscous mass hardens by evaporation of the essential oils, and what remains is the more or less hard, yellowish to brownish resin. Pure natural resins become soft and finally liquid when heated. They hardly dissolve in water, but in fatty or essential oils or in non-polar solvents . In contrast to pure resins, rubber resins also have a water-soluble part with the mucilage.

Historically, resins were used in a variety of ways, including in medicine, shipbuilding and painting as a binder and varnish . Today, natural resins are largely being replaced by synthetic resins, especially in industry.

Today synthetic resins are mainly used in the industrial but also in the artistic and restoration sectors. In industry, they serve as a reactive intermediate stage in the production of thermosetting plastics and are components in paints and adhesives . They are soft solids or highly viscous substances that usuallycontain prepolymers with reactive functional groups . Contrary to the recommendations of the IUPAC , crosslinked plastics (thermosets) are sometimes referred to as "resins" in the plastics industry. In painting they are used as a binding agent ( acrylic paint ) and as a finishing varnish, in restoration as a binding agent for retouching and also as a finishing varnish.

Natural resin

Natural resins are a mixture of different chemical substances. The predominant compounds in terms of quantity are resin acids , which belong to the carboxylic acids. Fresh resins continue to consist to a not insignificant extent of volatile and aromatic compounds. If these evaporate, the remaining material becomes tougher and harder. In addition, polymerization , crosslinking and oxidation reactions lead to solidification of the precipitate.

The resin of conifers , especially pine , which is predominant in most uses , is a tough, sticky, and strongly smelling liquid. It is light in oil and good in alcohol , partially soluble in gasoline , fine turpentine also in ammonia .

A distinction is recent , rezentfossile or semi-fossil and fossil resins. While recent resins come from trees that are still alive today ( turpentine , balsams , gum varnish , rosin , sandarac and mastic ), recent fossil resins have arisen from earlier representatives of tree species, some of which still exist today. These are called copals . Fossil resin is known as amber . The trees of origin can usually no longer be identified. Baltic amber is believed to come from a prehistoric species of conifer . Fossil resins are poorly soluble in alcohol.

Vegetable excretions without a resin fraction are mostly composed of polysaccharides and are water-soluble. They do not count among the natural resins. The rubber resins represent mixed forms of water-soluble and resinous components .

Education and acquisition

Tree resins are secondary metabolic products of the plants, which are conveyed to the plant surface via resin channels (see also biosynthesis of terpenes ). In the normal life cycle, resin-producing trees form “physiological resin”. After injuries, the amount formed increases, the "pathological resin" is used to close the wound.

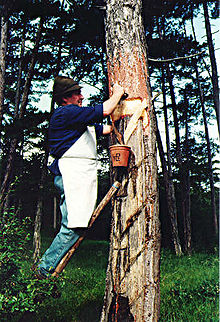

The systematic extraction of tree sap is done by resin . Artificial injuries are caused by scratching the bark and the escaping resin is collected in a container. Trees used include pine, larch and the sandarak tree . Fossil tree resins such as amber are obtained by searching abundant areas (e.g. beaches), prospecting or mining .

Processing and use

Probably the best-known natural resin product is rosin , which is mainly obtained from the resin of pine and spruce and is used in many products, e.g. B. as an adhesive for adhesive plaster, in chewing gum and for the treatment of bow hair on string instruments. Colophony is the solid residue that arises when conifer resin is heated after the turpentine oil has been distilled off. Colophony

saponified with alkali or modified by a Diels-Alder reaction with maleic anhydride is used in papermaking to render it hydrophobic. This process, known as sizing , improves the writability and printability of the paper.

Resins from both conifers ( turpentine , mastic ) and those from deciduous trees ( dammar ) played a major role in European oil painting . They have been used in combination with other substances to bind the color pigments since the 15th century . The quality of the oil-resin paints had several advantages over the previously common paints. Above all, it enabled a greater wealth of nuances through softer color transitions due to better miscibility. The tempera painting , the binding agent of which is emulsions, and the even earlier wax painting were thus displaced. In addition, resins have been used to make paints since ancient times .

In Greece, the resin of the Aleppo pine is added to wine, which gives it a special aroma. This wine is called retsina . Some tropical resins such as Elemi and Copal, and especially myrrh and frankincense, are still used today as incense .

Resins are extracts from dehydrated natural resins. They are used as intermediate products in the chemical industry, for example as synthetic rubber, for ship paints or for pigment production. Soaps made from resin, also for industrial use, are called dresinates . Resorcinol , a distillate made from natural resins, is used as an adhesion promoter in tire construction, as well as for the production of dyes, plastics, adhesives and flame retardants as well as in pharmaceuticals.

use

- Spirit varnishes traditionally contain binders such as rosin, copal or shellac (or today also novolaks , alkyd resins and vinyl polymers ) in volatile organic solvents such as ethanol .

- as a flux in electronic solders

- as lamp or candle fuel

- as an intoxicant, for example hashish , the resin from the hemp plant

- to improve ball handling e.g. B. in handball

market

The annual demand of the chemical industry in Germany for natural resins is estimated at 31,000 t (including natural waxes). Germany imports 5,000 to 16,000 tons of dehydrated natural resins every year. The predominant use of natural resins in terms of quantity is the manufacture of paints, varnishes and adhesives.

Synthetic resin

Resins (also synthetic resins are called) to ISO 4618: 2014 Paints and varnishes - terms by polymerization - polyaddition - or polycondensation synthetic resins. According to the IUPAC conventions , they are soft solids or highly viscous substances that usually contain prepolymers with reactive functional groups . Synthetic resins usually consist of two main components in processing. Mixing both parts (resin and hardener) results in a reactive resin compound. During the hardening process, the viscosity rises and when the hardening process is complete, an infusible plastic ( thermoset ) is obtained. After IUPAC the thermoset products (ger .: should thermosets ) can not be called resins.

Synthetic resins can be modified by natural substances, for example vegetable or animal oils or natural resins, such as. B. with alkyd resins . Natural resins that have been modified by esterification or saponification are also referred to as synthetic resins . In the broad sense and contrary to the recommendations of the IUPAC, all polymers are used in industry (especially in the English-speaking world) that are the basis for plastics, organic coatings or paints, etc. Ä. Are called resins. Thus, without the need polyethylene as polyethylene resin or in English as polyethylene resin designated. ISO 472: 2013 Plastics - Terms creates a highly inhomogeneous, hardly useful field of terms . The word resin is directly or indirectly equated with the word plastic as well as the molding compound used in a production process or generally with polymer .

Properties and processing

Synthetic resins are usually liquid or solid amorphous products with no sharp boiling or melting point . For industrial use, the resins are often available in the form of an emulsion or suspension or are produced in this form. Many of these resins are in principle also as real solutions used, but since it is in this most necessary solvents to volatile organic compounds is, this share is decreasing. In the case of classic resins such as phenolic resins, curing takes place via a polycondensation; they are therefore called condensation resins and must be processed under high pressures. Resins that cure to form thermosets without splitting off volatile components are important for industry. These resins are called reactive resins . An example of this are photoinitiated curing acrylates , with free radical polymerization taking place through UV or visible light. Epoxides, on the other hand, harden via a polyaddition, also without cleavage.

Curable molding compounds are usually free-flowing compounds which are processed into molded parts and semi-finished products in a hot-forming process with immediately subsequent irreversible curing at elevated temperature. In this case, high pressures are often necessary to completely fill the mold. Synthetic resin is often processed using a casting process. Here the casting resin is poured into a reusable or a lost mold.

history

- 1902: Development of the first technically usable synthetic resin ( Carl Heinrich Meyer ): phenol-formaldehyde resin ("Laccaïn"), a substitute for shellac

- 1907: "Heat and printing patent" by Leo Hendrik Baekeland → Hardening of phenolic resins : first thermosetting plastics ( Bakelite )

- 1910: Patent for Dr. Kurt Albert and Dr. Ludwig Berend for the first oil-soluble synthetic lacquer resin made from phenols and formaldehyde ("Albertole"), cf. also car paint

- until today: Creation of many types of synthetic resins and modification of their properties

Chemical subdivisions

-

Phenolic resins (phenol-formaldehyde resin, PF resin)

- Use: housing of electrical devices (between the two world wars); good insulator for electric current; Still versatile today ( ion exchanger )

- Production: polycondensation of formaldehyde and phenol

-

Aminoplasts : urea formaldehyde (UF resin), melamine formaldehyde resin (MF resin)

- Production: polycondensation of formaldehyde with urea or melamine

-

Epoxy resins :

- Use as casting resin; Composite material; adhesive

- most important production: polyaddition and condensation from polyhydric phenols and epichlorohydrin (with alkali lye)

-

Polyester resin (UP resins)

- Production on the basis of unsaturated polyesters (with other plastic components such as styrene )

- Use: paints, casting resins; Reinforcement of strength through glass fiber additives, pipe lining processes (sewer rehabilitation)

- Curing: Via peroxide-induced radical polymerization

- Polyester resins (saturated polyester)

- Manufactured from mainly saturated building blocks with excess hydroxy / carboxy

- Use: paints, liquid or powder

- Curing: cross-linking with melamines , isocyanates or epoxides

- ABS resins

- Mixture of resin and elastomer

- Basic monomers: acrylonitrile , 1,3-butadiene , styrene

- Important properties: strength, impact resistance and surface hardness

Further examples

use

There is a wide range of applications, corresponding to the large number of different resin types. Uses for glues , adhesives , lacquers , but also for the production of molded parts are typical .

Resins are used in the following areas of application:

- as a component of casting resins

- for the production of adhesives

- for the production of foams

- as impregnation resins (e.g. for electric motors)

- for the production of fiber-plastic composites (glass fiber reinforced plastic GRP , carbon fiber reinforced plastic CFRP , ..)

- for the production of wood fiber materials

- for overmolding integrated circuits with hardenable molding compounds

- in paints and coatings

- as a component of polymer concrete

- for raising buildings and floors by injecting them into the subsoil, e.g. B. after subsidence

- to secure geological structures by means of lacquer deductions

- for the manufacture of dentures

- for the production of injection preparations

swell

- Karl Hasel , Ekkehard Schwartz : Forest history. A floor plan for study and practice. 2nd updated edition, Kessel / Remagen 2002, ISBN 3-935638-26-4 .

- Egon von Vietinghoff : Handbook for the technique of painting. DuMont Verlag, Cologne 1983, (1991), (1994), ISBN 978-3-7701-1519-8 .

- Entry to resins. In: Römpp Online . Georg Thieme Verlag, accessed on June 13, 2014.

- Hans Dominighaus: Plastics. Otto Maier Verlag, Ravensburg 1974, ISBN 978-3-473-35405-4 .

- Jean H. Langenheim: Plant Resins - Chemistry, Evolution, Ecology, and Ethnobotany. Timber Press, Portland (USA) / Cambridge (UK) 2003, ISBN 978-0-88192-574-6 .

- Ernst Schwenk: 80 years of synthetic resins - almost forgotten inventors. Hoechst Aktiengesellschaft, Frankfurt am Main 1982, OCLC 312302809 .

- Klemens Fiebach: Resins, Natural. Pp. 1-2. In: Ullmann's Encyclopedia of Industrial Chemistry. Wiley-VCH, Weinheim 2005. doi : 10.1002 / 14356007.a23_073 .

Individual evidence

- ↑ Eberhard Tuescher, Matthias F. Melzig, Ulrike Lindequist: Biogenic medicines. A textbook in pharmaceutical biology. Wissenschaftliche Verlagsgesellschaft, Stuttgart 2012, ISBN 978-3-8047-2495-2 .

- ↑ Karl Hiller, Matthias F. Melzig: Lexicon of medicinal plants and drugs . 2nd Edition. Spektrum Akademischer Verlag, Heidelberg 2010, ISBN 978-3-8274-2053-4 .

- ↑ Entry on resin . In: IUPAC Compendium of Chemical Terminology (the “Gold Book”) . doi : 10.1351 / goldbook.RT07166 Version: 2.3.3.

- ↑ Gerd Collin, Rolf Mildenberg and Mechthild Zander: Resins, Synthetic. Pp. 1-2, In: Ullmann's Encyclopedia of Industrial Chemistry, 2005, Wiley-VCH, Weinheim. doi : 10.1002 / 14356007.a23_089 .

- ↑ Hubertus R. Drobner: SOUBIROUS, Bernadette. In: Biographisch-Bibliographisches Kirchenlexikon (BBKL). Volume 10, Bautz, Herzberg 1995, ISBN 3-88309-062-X , Sp. 839-843.

- ↑ Federal Statistical Office, 2008: Data on imports and exports of raw materials and selected products. Data status Sept. 2008.

- ↑ ISO 4618: 2014 (de), Coating materials - Terms. iso.org

- ↑ Entry on resin . In: IUPAC Compendium of Chemical Terminology (the “Gold Book”) . doi : 10.1351 / goldbook.RT07166 Version: 2.3.3.

- ↑ Entry on thermosetting polymer . In: IUPAC Compendium of Chemical Terminology (the “Gold Book”) . doi : 10.1351 / goldbook.TT07168 Version: 2.3.3.

- ↑ The Brockhaus, Science and Technology. 3rd volumes, Spektrum Akademischer Verlag, Mannheim; Heidelberg 2003, ISBN 978-3-8274-1168-6 .

- ↑ iso.org: ISO 472: 2013; Plastics - terms

Web links

- Thomas Seilnacht, Lexicon of Polymers and Plastics .

- Kern GmbH - Technical plastic parts, phenolic resin (PF) (12-03-06)

- Didactics of chemistry FU Berlin, plastics to get to know: epoxy resins (13-03-06)