Thermosetting plastics

Thermosets , correctly thermosets called, are plastics that can not be molded after hardening by heating or other means. They contain hard, amorphous , insoluble polymers . The macromolecules are closely networked via covalent bonds , which causes their lack of softening when heated, so they can only be machined after hardening. The preliminary products ( prepolymers ) are usually synthetic resins that are still meltable or soluble and - often with fillers and dyes - can be cast or hot-pressed. The prepolymers are tri- or polyfunctional compounds that polymerize with the aid of hardeners and possibly catalysts or through high temperatures and lead to close-knit crosslinking.

The terms synthetic resin and thermoset are not always clearly differentiated from one another. Correctly, a thermoset could be called a hardened resin . The fusible precursors for thermosets are also sometimes called thermosets themselves. In analogy to the fusible thermoplastics , the thermosets, which can no longer melt after curing, are also called thermodures . The English name is thermoset for a resin that hardens at an elevated temperature.

Classification

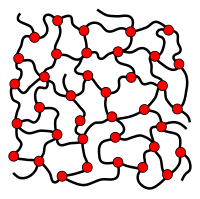

Duroplasts are one of three groups into which plastics are divided according to their mechanical-thermal behavior. A distinction is made between thermoplastics , elastomers and thermosets. While thermoplastics fusible are thermosets can not be melted due to their high crosslinking and break down after exceeding their decomposition temperature ( pyrolysis ). They react to high mechanical impact with cracks or cracks. The focus of thermoset plastics is on their high thermomechanical strength and, compared to metals, on their low specific weight.

Elastomers consist of wide-meshed cross-linked polymers. The wide mesh allows the material to stretch under tensile stress.

Thermoplastics consist of uncrosslinked polymers, often with a partially crystalline structure (shown in red). They have a glass transition temperature and are fusible.

General manufacturing

In order to manufacture thermoset plastic products, low-molecular pre-products (synthetic resins) are first obtained from monomers . The formation of the resins can take place via polycondensation or polyaddition , depending on the type of monomers . The resins are mixed with hardeners and possibly accelerators and additives such as dyes and release agents. The additives also include solid fillers and reinforcing materials (resin carriers), the proportion of which is often in the range from 40 to 65%. Fibrous resin carriers are added in the range of 12 to almost 80%. The resin carriers contribute significantly to the mechanical properties of the end product. The molding compositions obtained are brought into the desired shape, for example by compression molding, injection molding or layer compression. This is where the hardening (crosslinking) of the resins begins, often promoted by heat, but also by UV or IR radiation. The thermoset molding material obtained has a higher rigidity and hardness than a thermoplastic, is insoluble, hardly tends to deform under load and heat, but is more sensitive to impact.

The chemical process of hardening influences the production of a molding material. In the case of condensation resins , curing takes place via polycondensation. Condensate is usually water. Processing takes place at temperatures between 140 and 180 ° C and high processing pressure in order to prevent the water vapor from cracking the product. The hardening of phenolic resin , urea resin and melamine resin , for example , takes place via condensation .

In the case of reactive resins , curing takes place via polyaddition or radical chain polymerisation , i.e. without splitting off volatile compounds. Casting and lamination are possible here without increased pressure. Reactive resins play an important role in fiber-reinforced plastics . Fibers pre-impregnated with resins ( prepregs ) can be processed into laminates in a desired shape, which is then cured. Examples of reaction resins are epoxy resins , crosslinkable polyurethanes and unsaturated polyester resins .

application areas

- Brake pads

- in fiber composite materials such as carbon fiber reinforced plastic (CFRP) or glass fiber reinforced plastic (GFRP) as a matrix material

- Housings of electronic components

- Encapsulation of electronic assemblies

- Household (iron heat shield, pot handles and stove rails)

- Cable trays

- Body parts

- Circuit breakers and line circuit breakers

- Engine compartment applications (water pump housings, pulleys, commutators , intake manifolds, etc.)

- Reflectors (car headlights)

- Protective helmets, such as the fire helmet

recycling

Cured thermosets cannot be processed repeatedly due to the cross-linked polymer chains. The structure of the FRP can be broken up using mechanical or thermal processes and particulate and fibrous fractions can be recovered for reinforcement.

Individual evidence

- ↑ a b Der Brockhaus, Science and Technology , FA Brockhaus, Mannheim; Spectrum Academic Publishing House, Heidelberg, 2003.

- ↑ a b ISO 472: 2013 (de), Plastics - Terms . iso.org

- ^ Wolfgang Kaiser: Kunststoffchemie für Ingenieure , 3rd edition, Carl Hanser, Munich, 2011, p. 409ff.

- ↑ Romit Kulkarni, Peter Wappler, Mahdi Soltani, Mehmet Haybat, Thomas Guenther, Tobias Groezinger, André Zimmermann: An Assessment of Thermoset Injection Molding for Thin-Walled Conformal Encapsulation of Board-Level Electronic Packages . In: Journal of Manufacturing and Materials Processing . 3, No. 1, February 1, 2019, p. 18. doi : 10.3390 / jmmp3010018 .

- ↑ Dissertation