Melamine resin

Melamine resins (melamine-formaldehyde condensation resins, DIN - abbreviation : MF) are synthetic resins ( condensation resins ) that are based on the compounds melamine and formaldehyde and are aminoplasts . After curing through polycondensation , the resins form thermosetting plastics . In addition to the classic melamine-formaldehyde condensation resins, modified melamine resins such as melamine-phenol-formaldehyde resins (DIN abbreviation: MPF) and melamine-urea-formaldehyde resins (DIN abbreviation: MUF) are also produced.

history

Melamine was first presented by Justus Liebig in 1834 . Large-scale melamine resin production began in Germany and Switzerland between 1936 and 1938. In 1957, melamine-phenol-formaldehyde copolycondensates came onto the market.

Manufacture of melamine-formaldehyde condensation resins

As an intermediate hydroxymethylmelamines (Hexamethylolverbindungen) are prepared by addition of formaldehyde to melamine obtained in aqueous solution. Depending on the amount of formaldehyde, tri- to hexahydroxymethylmelamines are formed:

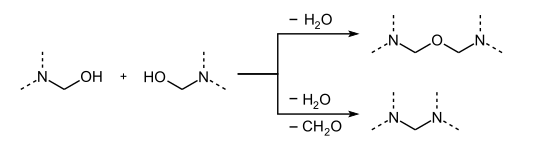

The product, which is soluble in water, is processed further as a solution or, after drying, as a powder. With fillers (e.g. cellulose ) and additives such as dyes and catalysts, molding compounds are obtained after drying . At 140–160 ° C under pressure, polycondensation takes place , which leads to insoluble and non-meltable molded parts or coatings. The condensation reactions lead to the linkage of the monomers via ether and methylene groups :

However, when fully cured, plastics that are closely linked via methylene groups are formed:

- Possible structure of a hardened melamine-formaldehyde resin. Dashed lines indicate the continuation of the macromolecule .

properties

The properties of melamine resins are clearly dependent on the aggregates. Compared to other thermosets, they are good weather and lightfast. They are permanently thermal (80–130 ° C), temporarily also 150 ° C, more with special settings (additives), and mechanically stable and are medium-quality electrical insulators. However, they tend to crack due to post-shrinkage. Melamine resins have a high surface hardness and scratch resistance, a high surface gloss, a high tracking resistance and good heat and moisture resistance. They are resistant to weak acids and bases, oils and fats, but not to strong acids and bases.

use

Melamine resins are used to manufacture molded parts with fillers (40–50%) for electrical insulating parts, switch parts, tableware, and fittings for cookware. As laminates , for example with paper, glass fibers or cotton fabric, they are used for furniture and door coatings. Precondensates are used as glue or varnish resins ( stoving varnishes ).

Modified melamine resins

- Melamine-Phenol-Formaldehyde Resins (MPF)

- Melamine-urea-formaldehyde resins (MUF)

- Melamine polyester

- MUPF glue

Trade names

- MF: Basotect (melamine resin foam), Melopas , Textolite

- MPR: Bakelite

- Laminates : Resopal , Resonit , SprelaCart

Individual evidence

- ↑ Entry on melamine resins. In: Römpp Online . Georg Thieme Verlag, accessed on June 20, 2014.

- ↑ Hans-Dieter Jakubke, Ruth Karcher (Ed.): Lexikon der Chemie . Spectrum Academic Publishing House, Heidelberg 2001.

- ^ A b Wolfgang Kaiser : Synthetic chemistry for engineers. 3rd edition, Carl Hanser, Munich 2011, p. 423 ff.

- ↑ Entry on melamine-formaldehyde resins. In: Römpp Online . Georg Thieme Verlag, accessed on June 20, 2014.

- ↑ Melamine resin foam from BASF, In: Basotect.de.