Acrylic resin

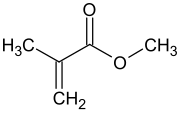

Acrylic resins , often also acrylate resins, are synthetic resins and are considered to be particularly durable. Acrylic resins are based on polymers or copolymers of acrylic acid , methacrylic acid and their esters . They are often copolymerized with other unsaturated monomers such as styrene or acrylonitrile . The resins can be thermally self-curing if they have functional groups, such as. B. carry hydroxymethyl groups or they are crosslinked for curing with other substances such as epoxy resins , (poly) isocyanates or aminoplasts .

application

Acrylic resins are used in many adhesives and paints . Another application is the sealing of buildings. In general, acrylic resins have a very wide range of applications in the paint industry. Once cured, acrylic resins are durable and solid, they have a good appearance, good gloss and high weather resistance. Acrylic resin in sealants can also be painted over, which is why acrylic is preferred over silicone sealants for sealing cracks in the wall. The exclusive use of pure acrylic resins on metal only offers moderate protection against corrosion . A perfect result is achieved with an appropriate primer. Acrylic resins are also used for this, but these are provided with appropriate additives ( adhesion promoters and pigments ). Then it is overlaid with acrylic resin, here again the use of appropriate fillers is necessary. This system is widely used, e.g. B. with steel bridges. The safety instructions should be observed during processing. Leaking monomers can cause headaches .

Photoinitiated hardening acrylates

Photoinitiated curing acrylates are one-component reactive resins which cure at room temperature and whose radical polymerization takes place through UV or visible light . Light-curing acrylates are used for bonds in which at least one part to be joined consists of a light-transparent material. These adhesives are used in the areas of communication electronics , entertainment electronics , the glass and plastics industries and in medical technology. The product properties range from curing in seconds for short cycle times in production, through high ionic purity and a wide range of elasticity, to the ability to combine different materials such as glass, ceramics, metals, plastics or wood.