Silicon dioxide

| Crystal structure | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||||||||

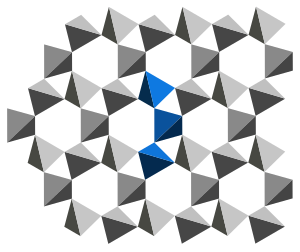

| The basic structural element of the various SiO 2 crystal structures is a tetrahedron in which one silicon atom is surrounded by four oxygen atoms. | ||||||||||||||||||||||

| General | ||||||||||||||||||||||

| Surname | Silicon dioxide | |||||||||||||||||||||

| other names | ||||||||||||||||||||||

| Ratio formula | SiO 2 | |||||||||||||||||||||

| External identifiers / databases | ||||||||||||||||||||||

|

||||||||||||||||||||||

| properties | ||||||||||||||||||||||

| Molar mass | 60.1 g mol −1 | |||||||||||||||||||||

| Physical state |

firmly |

|||||||||||||||||||||

| density |

depending on the modification between 2.19 and 2.66 g cm −3 |

|||||||||||||||||||||

| Melting point |

1713 ° C |

|||||||||||||||||||||

| boiling point |

> 2200 ° C |

|||||||||||||||||||||

| solubility |

|

|||||||||||||||||||||

| Refractive index |

1.458 (with amorphous thin film λ = 589 nm) |

|||||||||||||||||||||

| safety instructions | ||||||||||||||||||||||

|

||||||||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . Refractive index: Na-D line , 20 ° C | ||||||||||||||||||||||

| Breakdown field strength | 4–10 MV / cm (depending on the manufacturing process, e.g. with wet thermal oxidation 4–6 MV / cm with dry higher.) |

Silicon dioxide (often also silicon dioxide ) is an oxide of silicon with the empirical formula SiO 2 .

In the German language, is predominantly in the rubber - industry the term falsely silica silica used or also from the lately English silica acquired. The majority of the world's sand deposits consist of silicon dioxide ( quartz ), because this is not only common in the upper continental crust , but also particularly weather-resistant due to its hardness and chemical resistance. Silicon dioxide is the main component of all quartz glasses .

Mineralogy and Occurrence

Amorphous SiO 2

Non-crystalline (amorphous) SiO 2 occurs naturally as an essential component in the following substances, which are very inhomogeneous and inconsistent in their composition:

- biogenic: skeletons of radiolarians , diatoms and sponges made of opal , diagenetically solidified into rock , for example into silica slate

- Geyserite : amorphous sintered products from hot springs

- Tachylite volcanic glass basaltic composition, in addition to SiO: 2 greater levels of FeO , MgO , CaO and Al 2 O 3 contains

- Obsidian : volcanic glass of granitic composition

- Tektite : rock glasses , created by melting rock as a result of meteorite impacts

- Lechatelierite : pure natural SiO 2 glass, as it is e.g. B. occurs in tektites or in quartz sands when lightning strikes ( fulgurite )

- opal

- SiO 2 melt: at temperatures above 1727 ° C (at 1 bar)

Crystalline SiO 2

In contrast to the amorphous SiO 2 , the crystalline forms have only a very low tolerance towards impurities. They only differ in their structure.

- Mogánite ( chalcedony )

- α-quartz (deep quartz): Formation conditions: temperature T <573 ° C, pressure p <20 kbar

- β-quartz (high quartz): 573 ° C < T <867 ° C, p <30 kbar

- Tridymite : 867 ° C < T <1470 ° C, p <5 kbar

- Cristobalite : 1470 ° C < T <1727 ° C

- Coesit : 20 kbar < p <75 kbar

- Stishovite : 75 kbar < p <? kbar

As part of silicates such as e.g. B. feldspar , clay minerals or in free form as quartz the main component of the earth's crust and thus also the most common silicon compound.

Silica anhydride

In nature, support structures made of silicic acid anhydride occur in plant and animal life, for example in the diatoms ( diatoms ) and radiation animals ( radiolarians ) and glass sponges ( hexactinellida ) that are widespread in the sea, as well as in horsetail . The silicic acid anhydride skeletons of dead diatoms and radiation animals sink to the sea floor, accumulate there and form deposits of kieselguhr (diatomaceous earth) or radiolarian sludge. Deposits from the Miocene contain 70–90% SiO 2 , 3–12% water and traces of metal oxides.

Chemical properties

The solubility of silicon dioxide in water is strongly dependent on the modification or degree of order of the silicon dioxide. In the case of crystalline, highly ordered quartz, the solubility, depending on the source, is around 2.9 or 6-11 mg SiO 2 per liter of water at 25 ° C. It should be noted, however, that the solution equilibrium may only be established kinetically very slowly. The disordered amorphous silicas are much more soluble at the same temperature with approx. 120 mg / l water. The solubility increases with increasing temperature. For quartz at 100 ° C it is then approx. 60 mg / l water. In the case of amorphous silica, 330 ppm of silicon dioxide are dissolved in water at 75 ° C. The solubility also increases with increasing pH. The solubility of chalcedony is 22–34 mg / l, that of cristobalite is 6 mg / l, that of tridymite is 4.5 mg / l, that of stishovite is 11 mg / l and that of amorphous quartz glass is 39 mg / l l or 120 mg / l.

Acids are practically unable to dissolve SiO 2 , with the exception of hydrofluoric acid (HF), which attacks it with the formation of gaseous silicon tetrafluoride (SiF 4 ). Alkaline melts and - to a lesser extent - aqueous alkali solutions, in particular, dissolve amorphous silicon dioxide.

In addition to silica, some natural waters contain colloidal silicon dioxide (SiO 2 ), which does not hydrate to silica at normal temperatures in the water . This colloidal SiO 2 - which also includes various silicic acid-containing compounds - does not react with ammonium heptamolybdate to form the yellow-colored heteropoly acid .

Technical manufacturing

Synthetic SiO 2 , which is mostly amorphous , is produced in large quantities in various processes on an industrial scale. As a collective term is neudeutsch also "silica" is used.

The large-scale production of synthetic SiO 2 takes place mainly via precipitation processes , starting from water glass , which can be obtained by breaking up quartz sand with sodium carbonate or potassium carbonate . Depending on the process conditions , SiO 2 produced in this way is called precipitated silicon dioxide (historically: precipitated silicas ), silica sols or silica gels . Another important production variant is the production of so-called pyrogenic SiO 2 in an oxyhydrogen flame , starting from liquid chlorosilanes such as silicon tetrachloride (SiCl 4 ).

Fumed silicon dioxide

Pyrogenic silicon dioxide is amorphous SiO 2 powder with a diameter of 5–50 nm and a specific surface area of 50 to 600 m 2 / g. The name refers to the frequently used manufacturing process by flame hydrolysis: the water vapor produced during the combustion of oxyhydrogen decomposes silanes to SiO 2 , another method uses SiCl 4 as a Si source. In maintenance-free lead-acid batteries, pyrogenic silicon dioxide is used as the starting material for the gel electrolyte, but the mass fraction of SiO 2 is only a few percent.

Technical application

Synthetic SiO 2 plays a major role in everyday life, mostly unnoticed. It is just as important in paints and varnishes, plastics and adhesives as it is in modern manufacturing processes in semiconductor technology or as a pigment in inkjet paper coatings. As a non-toxic substance, it is found in pharmaceutical articles as well as in cosmetic products, is used in food processes (e.g. beer clarification) and as a cleaning aid in toothpaste. Silicon dioxide is also used in organic agriculture: there it is mixed with grain in the form of a fine powder to prevent grain weevil infestation . In terms of quantity, the main applications include the use as a filler for plastics and sealing compounds, especially in rubber articles . Car tires benefit from the reinforcement through a special SiO 2 system.

In terms of quantity, silicon dioxide in the form of glass is of the greatest importance . Mostly it is mixed with substances such as aluminum oxide , boron trioxide , calcium and sodium oxide in order to lower the melting temperature, to facilitate processing or to improve the properties of the end product. Pure silicon dioxide is quartz glass that is difficult to melt and is particularly resistant to temperature and temperature changes.

Quartz glass is used in optics in the form of lenses , prisms, etc. In the chemical laboratory , quartz glass is used as equipment glass as soon as particularly high UV permeability or temperature resistance is required. A glowing quartz crucible can be immersed in cold water without it cracking. Nevertheless, borosilicate glass , which is also resistant to temperature changes, is usually used in the laboratory , as it is cheaper to manufacture and process.

Another field of application for silicon dioxide is concrete production. This substance is the main component of microsilica , an additive in the production of high-performance and ultra-high-performance concrete (C100 ...). The silica fume reacts with the calcium hydroxide (Ca (OH) 2 ), which is released during cement hydration, and forms so-called calcium silicate hydrate phases. Furthermore, the particles in the order of 0.1 µm lead to a mechanical increase in strength by reducing the proportion of capillary pores in the cement stone.

SiO 2 is also used in the food industry as a food additive (E 551). It can be found, for example, in the form of silica as a trickling aid for table salt , in spices and spice mixtures. Due to concerns about the contained nanoparticles , Bio Suisse has terminated the approval of E 551 from the beginning of 2019.

In pharmaceutical technology, finely divided silicon dioxide is used as a pharmaceutical excipient in the manufacture of tablets.

Another possible use for silicon dioxide is in pyrotechnics . There it is used, among other things, for the production of fire gels .

Silicon dioxide in semiconductor technology

Silicon dioxide is an important material in semiconductor and microsystem technology . It is mainly used as an insulation and passivation material, for example as the gate dielectric of the transistors used or as an intermetal dielectric in the wiring level of integrated circuits . These layers are produced, for example, by thermal oxidation of silicon or by chemical vapor deposition and are mostly amorphous. Since the electrical properties are no longer sufficient for current microelectronic products, silicon dioxide has been gradually replaced by so-called low-k and high-k dielectrics since the mid-2000s . Another area of application of silicon dioxide (both quartz and special glasses) is photolithography , where it is used as a carrier material for masks.

Thin layers of silicon oxide can be produced by various coating processes. The simplest way to produce silicon oxide layers on crystalline silicon is to oxidize the silicon with oxygen (see Thermal oxidation of silicon ). This process takes place in tube furnaces, nowadays mostly vertical furnaces in the industrial sector.

The dry oxidation takes place at temperatures of 850–1200 ° C and proceeds relatively slowly, but with very good uniformity. In the case of wet oxidation, the deposition of the oxide is greatly accelerated. The moisture is introduced either directly in the form of water vapor or via an oxyhydrogen burner, i. H. Hydrogen and oxygen are reacted immediately before they are introduced into the furnace, with the desired water being formed in very high purity.

If silicon oxide is to be formed on a substrate other than silicon, thermal oxidation can no longer be used and other methods must be used. Chemical vapor deposition (CVD) processes are mainly used here , in which both elements are formed through a reaction of gases containing silicon, such as silane or tetraethylorthosilicate (TEOS, also tetraethoxysilane).

The oxide deposition processes, which are based on the reaction of silane, usually take place at reduced pressure ( low pressure cvd , LPCVD ). There are several common methods. In the LTO process ( low temperature oxide ), diluted silane is reacted directly with oxygen at approx. 430 ° C :

At higher temperatures (900 ° C), SiO 2 can be formed in the so-called HTO process ( high temperature oxide ), but also from a combination of dichlorosilane and nitrous oxide :

So-called TEOS processes are still important in semiconductor technology - tetraethylorthosilicate (TEOS) is thermally decomposed:

The SiO 2 layers produced in this way generally have better properties and can be deposited with greater layer conformity, but the production process is somewhat more expensive than, for example, with the HTO process.

toxicology

The effects of silicon dioxide on human health and the environment have been examined under REACH since 2012 as part of the substance assessment by the Netherlands. The assessment has not yet been completed. In particular, there are well-founded concerns when the substances are inhaled, as well as with surface-treated silicon dioxide in general. The authority is therefore requesting further data from the manufacturer. Several manufacturers appealed.

Amorphous synthetic silicon dioxide with a primary particle size <25 nm was approved as an insecticidal active ingredient on November 1, 2015 .

See also

Web links

- Researchers press the oxide of the semiconductor into a previously unknown crystal form www.wissenschaft.de: Under the enormous pressure of 268 gigapascals , silicon forms crystals that cannot be found anywhere else on earth .

- Comprehensive information on amorphous SiO 2 (opal)

- Photos of all SiO 2 modifications

Individual evidence

- ↑ entry to SILICA in CosIng database of the European Commission, accessed on 28 December of 2019.

- ↑ Entry on E 551: Silicon dioxide in the European database on food additives, accessed on August 11, 2020.

- ↑ Entry on silicon dioxide. In: Römpp Online . Georg Thieme Verlag, accessed on May 15, 2014.

- ↑ a b c d Silicon dioxide data sheet (PDF) from Merck , accessed on January 19, 2011.

- ^ A b c W. Hummel, U. Berner, E. Curti, FJ Pearson, T. Thoenen: Nagra / Psi Chemical Thermodynamic Data Base 01/01. Universal Publishers, 2002, ISBN 1-58112-620-4 , pp. 311-313. limited preview in Google Book search.

- ↑ refractiveindex.info: Refractive index of SiO2 (Silicon dioxide, Silica, Quartz)

- ↑ Edward Palik (Ed.): Handbook of Optical Constants of Solids: 1 . Academic Press Inc, 1985, ISBN 0-12-544420-6 , pp. 760 .

- ↑ Coating materials: terms from DIN standards . 1st edition. Vincentz [and a.], Hannover 2001, ISBN 3-87870-721-5 , pp. 157 ( limited preview in Google Book search).

- ↑ a b c d e A.F. Holleman, Egon Wiberg: Textbook of Inorganic Chemistry . Walter de Gruyter Verlag, Berlin, New York, 1985, ISBN 3-11-007511-3

- ↑ a b c Rudolf Rykart: Quartz monograph - The peculiarities of rock crystal, smoky quartz, amethyst, chalcedony, agate, opal and other varieties. Ott Verlag Thun, 2nd. Edition, 1995. ISBN 3-7225-6204-X .

- ↑ DC Ford, PW Williams: Karst hydrogeology and geomorphology. John Wiley and Sons, 2007, ISBN 0-470-84997-5 , p. 45 limited preview in the Google book search.

- ↑ J. Schlomach: Solid formation in technical precipitation processes. Dissertation, University of Fridericiana Karlsruhe, 2006, ISBN 3-86644-024-3 , p. 9.

- ^ Z. Amjad: Water soluble polymers: solution properties and applications. Verlag Springer, 1998, ISBN 0-306-45931-0 limited preview in the Google book search.

- ↑ L. Braunstein, K. Hochmüller, K. Sprengler: The determination of colloidal silica in water. In: VGB power plant technology. Vol. 62, No. 9, 1982, p. 789.

- ↑ This is new in organic farming 2019. (PDF; 277 KB) In: shop. fibl.org . Bio Suisse , 2018, accessed on January 27, 2019 .

- ↑ Production of silicon dioxide layers in semiconductor technology. Crystec Technology Trading GmbH, accessed April 25, 2009 .

- ↑ Community rolling action plan ( CoRAP ) of the European Chemicals Agency (ECHA): Silicon dioxide , accessed on 2017-07-05.

- ↑ Active Substances. Retrieved March 28, 2019 .