Speedhub 500/14

The Speedhub 500/14 is a bicycle - hub of the Hessian company Rohloff , which came on the market 1999th The name stands for the gear ratio range of over 500 percent and 14 gears. The many gears are also the unique selling point of the hub. With prices starting at 1050 euros, it is mainly used for high-quality touring bikes and in professional mountain biking .

General

The gear hub is only offered with a freewheel ; there is no version with a coaster brake . The Speedhub has an oil bath lubrication . It consists of 125 individual parts and weighs between 1.7 and 1.99 kg depending on the version; More than 10,000 copies are produced annually.

Versions

There are several variants of the hub:

| designation | use |

|---|---|

| TS | T ouring, S chraubachse, d. H. Solid axle for nuts |

| DB | D isc B rake, disc brake |

| CC | C ross C ountry (cross-country), rim brake, axis hollow drilled for quick release |

| E-14 | electronic gearshift control for e-bikes, specially developed by Bosch |

| EX | ex ternal gear mech |

| OEM | o riginal e quipment m anufacturer, original equipment manufacturers, only Rohloff- dropout |

| OEM2 | like OEM, for frames with disc brake mounts according to international standards (IS 2000) |

| T | T andem |

| XL | For fat bikes, with a clamping width of 170 or 177 mm |

| XXL | like XL, with 190 or 197 mm clamping width |

| B. | for 12 mm thru axle with 148 mm installation width ( B oost) |

There are hubs with solid axles (screw axles), with hollow axles for quick releases and for thru axles.

Depending on the dropout on the frame, the chain tension is set in different ways: With the dropouts open at an angle to the front on frames for gear hubs, the adjustment range is large enough to tension the chain by moving the rear wheel axle. Short dropouts of frames for derailleur gears make the installation of an additional spring-loaded chain tensioner necessary. The same applies to bicycles with a sprung rear wheel, as the distance between the bottom bracket and the rear wheel axle usually changes when the suspension is compressed. The use of quick-release axles is only intended for OEM failure and short dropouts that are open at the bottom, because the drive forces are so high that the axles cannot otherwise be held by the quick-releases.

There is an internal and an external switching control. With the internal switching control, the Bowden cables can be separated by means of a bayonet lock when the impeller is dismantled. With external switching control, the entire control is removed from the hub. When using a disc brake, the external gearshift control must be used.

The construction was protected by several patents.

technology

Gearbox structure

Three planetary gears connected in series work inside the hub . The 1st and 2nd gear stages are built in mirror image with identical gears, while the 3rd gear stage is built with different gears and a different scheme. The interaction of the first two levels results in a total of seven gears, by switching the third level on and off this number is doubled to 14. All planet gears have roller bearings in order to achieve a high level of efficiency.

The gear ratio , the quotient of the rotational speed of the ring gear and hub speed is depending on the selected gear is between 1: 0.279 and 1: 1.467. The gear ratio range, i.e. the ratio of the highest to the lowest gear, is 526 percent. The gear ratio is divided into 13 even jumps of 13.6 percent each. The 11th gear is designed as a neutral gear with a transmission ratio of 1.

The friction losses of the drive are between one and five percent, depending on the gear, and are therefore no greater than high-quality derailleur gears.

Assembly

The difference in torque between the input side of the hub (ring gear) and the output side (rear wheel) must be introduced into the rear of the frame, as with every gear hub. This can be done with an appropriately shaped dropout (OEM versions) or with the torque arm shown above . Both prevents twisting of the axis of the rear wheel inside the bicycle frame while pedaling the pedals .

The switching mechanism works positively controlled by two Bowden cables and a rotary switch handle. The notch for the gears is integrated into the hub of the Speedhub. Compared to the otherwise widespread solution of accommodating the detent in the switch handle, the setting of the Bowden cables to the rotary switch handle is therefore not critical. Only the gear marks on the twist grip are incorrect if they are incorrectly adjusted, but the function of the gearshift is retained. If the cables are adjusted very strongly, the rotary switch handle can hit its stop before the first or last gear in the hub is reached.

The correct setting of the tension is not directly necessary for the function of the hub, but it does influence the switching precision. If shifting becomes difficult due to insufficient play in the trains, the gears cannot be changed properly. The same applies to extremely increased play in the shift cables.

The shifter can be mounted on the right or left of the handlebar, and the direction of rotation for shifting into the higher or lower gears can also be freely selected. However, if the gear markings on the gearshift handle are to be legible and accurate, a preferred direction of rotation and installation on the right end of the handlebar are specified. An assembly on conventional racing handlebars is only possible at the handlebar end. However, Gilles Berthoud does offer a three-part aluminum shifter for racing handlebars.

Since 2014 cinq5 has offered a shift lever called Shift: R ; it consists of two levers that are mounted on the left and right of the handlebar and are used to shift up and down. A version is also available for racing handlebars.

The frame clamp widths correspond to today's standards of 135 mm to 197 mm in bicycle construction. The hub weighs between 1700 g (CC) and 1995 g (CC DB OEM XXL fat bike versions 190/197 mm), depending on the version. The oil filling is 25 ml. The manufacturer recommends changing the oil once a year, but at least every 5000 kilometers .

The sprocket of the hub is designed for bicycle chains 1/2 × 3/32 ″ (8-speed circuit chains ) or a Gates toothed belt .

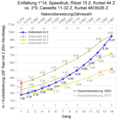

Development of the Speedhub compared to a derailleur

Sprockets and chainrings

Originally the hubs were fitted with helical sprockets. The hub was delivered as standard with a 16-tooth steel sprocket, rims with 13, 15 and 17 teeth were also offered. The gear rims with 15, 16 and 17 teeth were designed as mirror-symmetrical reversible gear rims in order to increase the service life. For bicycles with small wheels (for example 20 ″ in folding or recumbent bikes) a special helical gear rim with 13 teeth was offered. This made it possible to achieve great unfolding even with these bikes. This sprocket required a modified chain line (58 mm instead of 54 mm) and was not designed as a reversible sprocket, but cranked. For frames with a dropout thinner than 5 mm, a long fastening screw had to be used for the chain tensioner when using the 13 mm sprocket and at the same time using a chain tensioner.

However, Rohloff stopped selling the helical sprockets. Freewheel sprockets can still be purchased with 16 teeth on a transitional basis. Individual suppliers also have other sizes in stock. Instead of helical sprockets, plug-in sprockets are now used, which can also be assembled without special tools. An adapter ("Splined Carrier") is screwed on for this purpose and serves as a carrier for the sprockets, which expand the previous range with 13 - 19 and 21 teeth. The gear rim with 16 teeth remains standard. The adapter shifts the chain line 3 mm outwards. If this change is not desired, a more compact adapter (“Splined Carrier S”) can be used, which, however, cannot be used with the sprockets with 13 and 14 teeth.

For the front chainrings with 42, 44 or 46 teeth are recommended. The 42 chainring is standard on most bikes. On bicycles with small wheels, much larger chainrings are also fitted at the front

The Speedhub can be combined with the Gates Carbon Drive toothed belt drive , but this requires particularly stiff versions of the rear frame of the frame.

Comparison with other circuits

In contrast to derailleur gears, hub gears are characterized by compact, closed designs. The chain can easily be surrounded by a closed chain case. This protects the drive elements (including the chain) from dirt and water. The chainring is always optimally aligned with the sprocket , regardless of the gear selected . The wear-inducing skew of the chain, which is common in chain shifts, is avoided. Chain wear can be further reduced by installing a comparatively wide chain (1/2 × 1/8). However, practically all current gear hubs and single cranksets are designed for narrow chains (1/2 × 3/32), so this advantage hardly plays a role. Overall, the circuit is very low-maintenance. Another advantage compared to derailleur gears is the possibility of symmetrically spoking the rear wheel. This reduces the risk of broken spokes.

There is no significant wear within the hub. Maintenance inspections with prophylactic replacement of the wearing parts only take place at the manufacturer, but are only due after around 100,000 km.

The hub is mainly used by bicycle travelers and extreme mountain bike athletes. For this group, reliability and durability are more important than price. The Speedhub 500/14 is rarely found on everyday bikes, as the price is too high for the majority of cyclists in an individual cost-benefit comparison ( street prices: Speedhub 500/14 from approx. 800 euros, Shimano SG-S700 from approx. 300 Euro).

The gear ratio range of the Speedhub 500/14 of 5.26 is larger than that of other shift hubs and corresponds to the usual derailleur gears. The spread between adjacent aisles is always and invariably close to 1.136. This uniformity, which cannot be achieved with chain connections, is disturbed by differences in efficiency and is only advantageous on long inclines. In the flat country, some drivers prefer a smaller spread in high gears, in city traffic with frequent starts a larger spread between the small gears.

There is a twist grip for shifting gears, which is not compatible with racing bars. There are “plugged together” but very wide drop bars or special stems that accept a Rohloff twist grip, but the selection is limited. Third-party providers have developed solutions that allow use with commercially available brake levers. The electronic gearshift E-14 is available for e-bikes with Bosch or Panasonic drives.

Operation is easy as all 14 gears can be shifted with just one handle. In contrast, most derailleur gears and some older gear hubs have two shift levers (Sturmey Archer 5-speed until around 1980).

Many circuits have a detent on the handlebar. However, since the gears are changed on the rear wheel, the friction and elasticity of the shift cables and cable sleeves interfere with clean shifting. The switching drive of the Rohloff Speedhub locks into place within the hub. It is therefore the only bicycle gearshift that does not require any adjustment work.

Driving in gears 5 and 7 is often noisy, as all the gears of the planetary gears turn in these two gears. The noise development varies from hub to hub. In connection with some frame types , additional resonances can occur, which amplify the noise of the hub. The noise level is reduced within the run-in period of around 1000 kilometers. Missing gear oil or one that has been diluted for winter operation can also be a cause of increased noise development.

At 1.7 kg, the hub is hardly heavier than a Shimano XT derailleur, but comparable to other hub gears.

The market leader Shimano launched a competing product in 2010. The Shimano SG-S700 hub gear has 11 gears at around 35 percent of the price of the Speedhub (around 300 euros), is almost 10 percent heavier than the Speedhub 500/14, is also equipped with oil bath lubrication and has a gear ratio of 409 percent. However, it is not designed for the loads that occur in off-road sports and is therefore not approved for MTB use. The only alternative to the Rohloff Speedhub is the P1.12 gear hub from Pinion; However, this is a bottom bracket gear shift and not a rear hub gear shift.

In 2012, a new, lighter shifter was introduced. In the past, there has been criticism of the material that wears out with prolonged use, as well as the fact that you could not see the gear set. Both were fixed with the new handle.

| Spoke Flange Distance: | 60 mm, symmetrical |

| Spoke hole circle: | 100 mm |

| Number of spokes: | 32; since 2011 also 36 |

| Diameter at the dropout: | 9.8 mm |

| Oil filling: | 25 ml |

| Spider thread: | M34 × 6 P6, tolerance field H6 |

| Chain line: | 54 mm |

| Shift handle rotation angle per gear: | 21 ° |

| Shift cable per gear change: | 7.4 mm |

| Housing surface: | Polished aluminum or anodized in red or black (since 2009) |

| Dimensions: | 1700 g (CC), 1800 g (CC EX), 1825 g (CC DB) |

Web links

- Product Speedhub on the manufacturer's website

- Download overview page of the manufacturer There are also documents on Speedhub (PDF)

- Video of the oil change on the hub (Youtube, 7 min)

Individual evidence

- ↑ Rohloff AG end consumer price list, as of October 2019. Rohloff AG, accessed on April 2, 2020 .

- ↑ Inventor from North Hesse develops the world's best bicycle hub. Archived from the original on February 3, 2014 ; accessed on January 17, 2016 . (PDF file; 208 kB), Hessen Agency, Current News, February 2009.

- ↑ Innovations: The world's best bicycle hub comes from Hessen. In: Financial Times Germany. April 16, 2009.

- ↑ Why does the SPEEDHUB 500/14 not have a coaster brake? on rohloff.de

- ↑ Patent DE19720794 : multi-speed gear hub . Registered on May 16, 1997 , inventor: B. Rohloff.

- ↑ Patent DE19720796 : Multi-speed gear hub for bicycles. Registered on May 16, 1997 , inventor: B. Rohloff.

- ^ Peter Barzel, Michael Bollschweiler, Christian Smolik: The new bicycle technology 2nd edition. BVA - Bielefelder Verlag, 2010, ISBN 978-3-87073-322-3 , pp. 245–249.

- ↑ Shift: R is delivered on http://cinq-five.blogspot.de/

- ↑ Gates Carbon Drive with SPEEDHUB 500/14 on rohloff.de

- ↑ Switching faults at low temperatures - drive the SPEEDHUB 500/14 without problems in winter. on rohloff.de

- ↑ Stiftung Warentest : Overview of bicycle gears (October 25, 2012)

- ↑ Shimano Alfine 11-speed from importer Paul Lange

- ↑ Speedhub lighter than Alfine 11-speed

- ↑ Shimano brings 11-speed hub ( Memento from December 30, 2010 in the Internet Archive ) to radfahren.de

- ↑ Pinion gear hub gear P1.12