Bowden cable

The Bowden cable [ ˈbaʊ̯dn̩ˌʦuːk ] (according to DIN 71986 “cable”) is a movable machine element for the transmission of mechanical movement as well as compressive and tensile forces by means of a flexible combination of a wire cable and a shell that is pressure-resistant in the direction of travel.

The Bowden cable is named after its inventor, the British Ernest Monnington Bowden (1859–1904). Depending on the intended use, the Bowden cable is also referred to as a brake cable, shift cable, accelerator cable, clutch cable, etc. Bowden cables for the transmission of compressive forces are, for example, shift actuators for connecting mechanical selector levers and gears, cable releases for cameras or the shift cables of bicycle gears.

construction

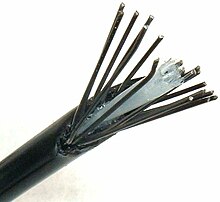

The Bowden cable consists of a steel wire or wire cable ( core , pull cable , inner cable or inner cable ), which is laid in a flexible, but pressure-resistant sleeve ( Bowden cable sleeve or cable sleeve ) in the direction of tension . The shell is used to guide the train and as a counter-bearing to support the tensile forces to be transmitted. The Bowden cable can transfer tensile forces along any curved path (as long as the radius does not fall below a certain level). If the Bowden cable runs in a curve, the support of the inner cable pull creates pressure forces in the sheath. This compresses the envelope.

A flexible sliding tube (inner lining, sliding inner tube) made of POM , PE or Teflon can be inserted between the cover and the pull rope . Sometimes a plastic-coated rope is used. Soft PVC is usually used for the outer covering of the envelope . The jacket must follow the bends in the jacket without tearing. It protects the train and introduced lubricants from dust and moisture and thus prevents corrosion ( rust ), increased friction and freezing.

Usually the whole length of the soul is greased before being threaded. Lubricating nipples or oilers can be attached to the cover for relubrication.

In the automotive industry, grommets and bellows are often used to seal the covers. The same applies to cantilever brakes on bicycles , because here the shell mouth is in the spray area of the tire. To avoid corrosion and freezing of the cable by standing water, Bowden cables in particular must be protected from the ingress of water, both ends of which point upwards. Alternatively, a drain should be provided at the lowest point of the envelope.

Versions of the envelope:

- Spiral cover : the original and most common version. A tightly wound spiral made of square or round wire ensures compressive strength. Spring steel is used as the wire for winding the spiral, and an aluminum alloy for weight-optimized versions. If a flexible guide tube is inserted between the spiral and the pulling cable, the outer hose-like covering of the spiral, which is then usually made of stainless steel , can be dispensed with .

- Compression-free casing : steel wires arranged parallel to a ring run in the longitudinal direction of the casing. The wires are embedded in tough elastic plastic on the inside and outside to create cohesion. This version was designed for derailleur gears on bicycles in order to minimize the change in length when the cover changes position. No high tensile forces can be transmitted, as the inner steel cable would otherwise drive the wires of the sheath apart. Instead of steel wires running in a straight line, fiberglass wires can also be used if the demands on compressive strength are lower. The Bowden cable core consists of a single wire, can also pressure forces are transmitted ( push-pull Bowden cable or train-pressure actuating cable ).

- Link-like cover : Individual, fixed sleeve segments made of steel, aluminum or plastic are articulated together. Brand names are Nokon and I-Link . A flexible tube is drawn into the joint casing to stabilize and improve the gliding ability. Advantages are the low weight compared to the spiral cover, the possibility of laying narrow radii and the position-independent constant length of the central axis (comparable to the compressionless cover ). This system was patented in 1996 by Norbert Nötzold.

The connection of the pull rope with the machine part to be moved is done either by frictional clamping or by hanging a nipple in a suitably shaped eyelet. It is important to avoid sharp bends and contact between the Bowden cable core and hard shoulders or edges in order to prevent premature breakage. Nipples can be attached to the Bowden cable core by pressing, brazing , zinc die casting or screwing. Pushed Bowden cables are usually provided with wire pins for the introduction of force, which are only connected to the core in the sheath, in order to prevent the core from kinking under pressure outside the sheath.

Further system components:

- The cable guide (At the bicycle brake cable - or Shifting ) receives the end of the sheath and guides resulting from the envelope pressure force into the component from.

- The stop sleeve ( end cap ) is pushed or pressed ( crimping ) onto the end of the sleeve , so that it is firmly seated in the pulling support or in the adjusting screw.

- The inner cable end cap is pushed onto the free end of the cable and pressed to protect it from splicing. Alternatively, the end of the rope can also be fixed with a fusible link.

- Adjusting screws are used as an adjustable counter bearing . In-line set screws are used along the envelope. With them, the effective length of the cover can be changed in order to adjust the Bowden cable. (Alternatively, the adjustment is made by changing the effective length of the pull rope.)

- A sealing cap or cuff protects the annular gap between the end of the cover and the pull rope against the ingress of dirt and water.

In sections, the pull rope can run freely tensioned between two pull counterholders (at which the Bowden cable sheath ends). In the free course it can be deflected via rollers, sliding guides or guide tubes (for example on bicycles to save weight and reduce the operating force). A pull rope deflection using rollers or a guide tube enables tighter radii.

Areas of application

Are used Bowden cables for the actuation of brakes and gears in bicycles , as gas and clutch in motorcycles , as well as in motor vehicles for actuating the parking brake , the unlocking of the boot and tank cap and for driving the transmission . In precision engineering , Bowden cables are used, for example, as a release mechanism (“cable release”) in photo cameras . In aviation , cables are used to operate the rudder and control flaps. An early example is Engelbert Zaschka's experimental aircraft or helicopter from 1928.

In the past, the cable was used for all types of braking systems. It was later replaced by the hydraulic brake or other systems that are more reliable and require less actuation forces. For example, the standard version of the VW Beetle was equipped with cable brakes until 1962.

Norms

- DIN 71984-1: 1982-10 cables; Round strand rope 7 × 7 (Cables for controls; Round strand 7x7)

- DIN 71984-2: 1982-10 cables; Round strand 1 × 19 (Cables for controls; Round strand 1x19)

- DIN 71984-3: 1982-10 cables; Cable sheaths (cables for controls; sheatings)

- DIN 71984-4: 1982-10 cables; Sleeves (cables for controls; sockets)

- DIN 71985-1: 1982-08 nipples for cables; Receiver nipple (Nipples for cables for controls)

- DIN 71985-2: 1982-10 nipples for cables; Solder nipples (Nipples for cables for controls; Nipples for soldering)

- DIN 71985-3: 1982-08 nipples for cables; Clamping nipples (Nipples for cables for controls; Clamping nipples)

- DIN 71985-4: 1982-08 nipples for cables; Pressnippel [Pressnippel] (Nipples for cables for controls; Nipples for swaging)

- DIN 71986: 1985-02 cables; Overview, application examples (Control cables; Summary, application examples)

- DIN 71989: 1982-10 Adjusting screws for cables for controls

- DIN 71990: 1982-10 cables; Inner tubes for cable sheaths (Pipes for sheatings of cables for controls)

- DIN 71991: 1982-08 Threaded end-fittings for cables for controls

- DIN 71992: 1982-10 Eye-fittings for cable for controls

- DIN EN 2348: 1989-11 Aerospace; Cables for aircraft controls; Technical delivery conditions (Aerospace series; Control cable assemblies; Technical specifications)

- LN 29503: 1964-11 Technical delivery conditions for cable assemblies for aircraft

- LN 9361: 1991-12 cables; Not for new designs (Cable assemblies; Not for new design)

materials

Bowden cables are typically made from the following materials:

Soul:

- Galvanized steel stranded rope

- Wire made of NiRo steel material no. 1.4401

- Steel wire (for tensile and compressive force) NiRo No. 1.4310

Sheathing of stranded ropes:

Cover:

Covering the shell

Lining the shell

- HDPE (white)

Fittings such as sleeves, nipples and others:

- Brass blank for soldering

- Nickel-plated brass

- aluminum

- galvanized steel

- NiRo steel

Connections can be made by soldering, pressing, screw clamping and form locking via molded nipples.

literature

- Fritz Winkler, Siegfried Rauch: Bicycle technology repair, construction, production . 10th edition, BVA Bielefelder Verlagsanstalt GmbH & Co. KG, Bielefeld 1999, ISBN 3-87073-131-1

- Richard Hallet: Bicycle Maintenance-Care-Repair . 1st edition, BVA Bielefelder Verlag GmbH & Co. KG, Bielefeld 2003, ISBN 3-87073-308-X

- Rob van der Plas: Bicycle repairs made easy . 1st edition, BVA Bielefelder Verlaganstalt, Bielefeld 1996, ISBN 3-87073-185-0

- Max Bohner, Richard Fischer, Rolf Gscheidle: Expertise in automotive technology . 27th edition, Verlag Europa-Lehrmittel, Haan-Gruiten 2001, ISBN 3-8085-2067-1

- VdTÜV research report 243, Edmund Donath: "Determination of the efficiency of brake cables taking into account the different types and installation variants", Verlag TÜV Rheinland, Cologne, ISBN 3-88585-546-1

Web links

Individual evidence

- ↑ Patent GB189625325 : New or Improved Mechanism for Transmission of Power. Published September 25, 1897 , inventor: Ernest Monnington Bowden.

- ↑ Patent GB189714402 : Improvements in and relating to Brakes for Velocipedes and other Road Vehicles. Published May 14, 1898 , inventor: Ernest Monnington Bowden.

- ↑ Patent US609570 : Mechanism for Transmitting Motion or Power. Published 23 August 1898 , inventor: Ernest Monnington Bowden.

- ↑ Patent GB189801196 : Improvements in and relating to Brakes for Velocipedes. Published November 19, 1898 , inventor: Ernest Monnington Bowden.

- ↑ Patent CH27570 : New type of cord for the transmission of tensile forces. Published January 31, 1904 , inventor: Ernest Monnington Bowden.

- ↑ Lubricating nipple , In: Bowdenzug24.com

- ↑ Products> Wire strands, Bowden sleeves & Bowden spirals ( Memento of the original from April 22, 2016 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. seilzuege.at, AMW Anton Müllner Vienna, Anton Müllner GmbH, manufacturer, accessed December 3, 2017.