Spar-rib construction

The spar-rib construction (often just called rib construction) is the classic form of the structure of a wing in aircraft construction . A distinction is made between three variants: open, half-open and closed construction. In the open construction, the basic structure is only covered with fabric, in the semi-open construction the front closed area contributes to the overall strength and in the closed construction the entire outer skin of the wing contributes.

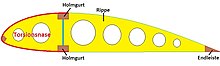

Spars

One or more wing spars are the load-bearing components of a wing. They have the task of absorbing the bending moments acting on the wing in the direction of the span, unless this task is completely taken over by struts or tension cables. In addition, the spars are used to attach the wing ribs. Auxiliary spars are used where flaps or oars have to be attached. Spars consist of an upper chord, a lower chord and an intermediate part which absorbs the pressure and shear forces. The structure can be designed as a tube, as a closed box, as an I-beam or as a C-beam.

Leading edge

With an "open" rib-spar construction, as most aircraft had in the time of the First World War , there is a profiled strip on the leading edge of the wing. This serves to maintain the shape of the wing nose. A leading edge can also be present in the “half-open” construction, but only reinforces the planking of the wing nose or serves to make the plywood planking easier and to fix the ribs. In metal aircraft construction, “leading edges” are rare.

Trailing edge

The trailing edge is the counterpart to the leading edge on the wing's trailing edge. Often only one wire was stretched, which led to the typical undulating trailing edge of a wing on biplanes after they had been stretch-coated .

Ribs

Wing ribs are used to give the wing its aerodynamic shape ( wing profile ). The ribs can also be constructed in a half-timbered construction, punched from sheet metal or just formed from rigid foam in order to counteract the collapse of the planking. With the open rib construction, the ribs are built over the spars at the top and bottom so that there are no kinks in the profile contour. Furthermore, so-called half-ribs are often attached in front of the first spar between the actual ribs in order to improve the profile accuracy. With the semi-open rib construction, the spar is built as high as possible and the front parts of the ribs are flush with it in order to be able to accommodate the later planking, which is definitely pulled over the main spar. In the front area, spars and ribs are smaller than the original profiles by the material thickness of the later planking (planking deduction). The rear rib areas are then to their original dimensions. With the closed rib construction, the entire wing is clad with birch plywood or sheet metal (often unblocked balsa wood in model construction) and the ribs are all around smaller than the original profile.

Planking (torsion nose)

In the semi-open rib construction, the front paneled part of the wing, together with the main spar and its pressure webs, forms a closed tube in the form of an elongated large D, in the corners of which the spar chords are located. This network absorbs further air forces, but above all the torsional forces. The wing is thus torsionally stiff. The German name is "Torsionsnase", in English it is called D-Box . With the introduction of closed wing noses, an aerodynamically more favorable, non-braced, self-supporting wing construction became possible. Even with the closed design, the outer skin absorbs these forces.

Covering

In the open and half-open design, textiles or textile foils are applied that tighten themselves when exposed to heat or have to be tightened with tension varnish. In model construction, smooth films with a hot-melt adhesive coating are used, which are ironed on and shrink at higher temperatures. The covering also absorbs a small part of the torsional forces. With the open design, the tension of the tensioning varnish causes the covering to collapse both in the direction of flight and in the direction of the span. This means that the specified profile is only adhered to directly on the ribs. In the case of the semi-open design, however, sufficient profile accuracy is achieved at least in the relevant nose area.

Limits

The spar-rib construction is easy to manufacture and therefore has a permanent place in aviation. The most common representative of the closed design is the Cessna 172 , the semi-open design the Piper J-3 or PA-18 and the open design the Polikarpow Po-2 (→ list of the most popular aircraft ). However, adequate profile accuracy by today's standards (introduction of laminar profiles) cannot be achieved with these construction methods. The plastic shell construction already resulted in performance improvements of 15 to 25%, especially at higher flight speeds (e.g. Schleicher Ka 6 compared to fs 24 Phoenix ) when it was introduced . In ultra-light and motor aircraft construction, too, there is an increasing trend towards plastic half-shell construction .

literature

- Hans Jacobs : Workshop practice for the construction of gliders and gliders. Otto Meier Publishing House, 1935

- G. Brinkmann / H. Zacher : The evolution of the gliders. Bernard & Graefe 1999, ISBN 978-3-7637-6119-7