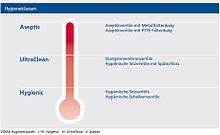

Hygiene class

The concept of hygiene classes creates a suitable link between the hygienic requirements between the machine and the product to be processed. The Association of German Mechanical and Plant Engineering (VDMA) has established helpful guidelines for the industry with various specialist publications on hygiene classes, especially in the field of filling technology. A basic distinction is made between the 3 main classes “Hygienic”, “UltraClean” and “Aseptic”, with the “Hygienic” class again being divided into 3 further sub-categories.

Classification by microbiology

The hygiene classes can be described by microbiological , physico-chemical and resulting sensory properties. Another important parameter for the classification of products to be produced is the minimum shelf life.

The indicated minimum shelf life depends primarily on the microbiological stability of the product, and also on the planned distribution logistics. The matrix is used for orientation in the division into the Hygienic, UltraClean and Aseptic classes , whereby one characteristic can already be decisive.

Important decision criteria are therefore the type of food and its suitability as a breeding ground for microorganisms. A distinction is made here between pathogenic, i.e. food poisoners, and non-pathogenic organisms. The latter have no direct impact on human health, but can very well have undesirable effects on the food itself. Ultimately, the consumer judges the manufacturer and its brand quality by taste, smell and appearance. In view of the important product image, product safety and the required process safety have top priority.

The germ reduction required for microbial stability and minimum shelf life, measured in the logarithmic reduction in the germ count, is primarily achieved through direct or indirect heat treatment. The necessary germ reduction is to be achieved, taking into account the heat resistance of relevant microorganisms, measured in terms of D and z values. These values are specific for microorganisms and can also be influenced by the food matrix, especially by fat and protein. The microorganisms can also occur in different forms, vegetative and non-vegetative, and influence the germ reduction within the food through the process. The aim is to negatively influence the physicochemical, nutritional and sensory properties of the product as little as possible.

Hygiene classes for process components

Process valves can help to minimize or even prevent the risks of microbial contamination. This already applies before the germ reduction, especially since the germination rate of the raw product is an important indicator for the reduction kinetics of microorganisms and accordingly also for the process and product safety and product quality.

The specific requirements for valve technology are different for each hygiene class and are further described below.

Hygienic

Requirements for the process components

The essential basic requirement for process components for direct contact with food is uncompromising hygienic design. In order to meet the basic requirement, according to the Machinery Directive, the design must be carried out in such a way that any risk of health hazards is excluded. In particular, the materials used must be able to be cleaned before each use and surfaces that come into contact with the product must not offer any space for microorganisms to nestle, e.g. B. elevations, depressions or edges. The background to this requirement is the indispensable requirement to be able to produce food safely and of consistent quality with an appropriate shelf life.

Ensuring a consistently quality and controlled process system is the key to achieving this ambitious goal. In hygienic systems, this is achieved through a cleaning process that is tailored to the product and the system and which safely returns the system to the desired initial state before each production. Components of the Hygienic class are designed in such a way that they are cleaned just as reliably and completely as the connected piping system. The distinguishing feature of components in the Hygienic class is not in the cleaning ability per se, but often in the efficiency of the cleaning. The hygienic design of the components determines the necessary intensity of the cleaning process and thus the use of the four parameters of the Sinner circle , namely time, temperature, chemistry and mechanics, in order to completely clean the fitting. The efficient possibility of cleaning a component is also underlined by the existence of relevant certificates such as EHEDG , 3A etc. These certificates all stand for hygienic design and, in the case of the EHEDG, for the cleanability of a valve compared to a reference pipe under controlled and standardized conditions.

The following valve concepts are traditionally used for “hygienic” processes

- Butterfly valve: Butterfly valve is the most common and simplest form of hygienic valve on the market. This type of valve is particularly popular due to the inexpensive possibility of shutting off the product flow within a pipeline.

- Seat valves: Seat valves (or lift valves) are used to shut off a pipeline. The valve is characterized in particular by the sealing surface that comes into contact with the product, which is less in contact with the product than the butterfly valve, and its torsion-free load with defined compression. In addition, two pipelines lying one above the other can be safely shut off from one another using seat valves, which leads to a considerable increase in productivity in the process.

UltraClean

The following valve concepts are traditionally used for “UltraClean” processes

- Valves with flush lock: The flush lock can be attached to existing hygienic valves and is used to prepare hygienic installations on the valve side for UltraClean processes. The classic valve rod seal is overlaid and secured with a vapor barrier. Basically, the vapor barriers used are so-called damping of the interface. There is no provision for pressure build-up to reach sterilization temperatures, which is why the flush lock cannot be equated with a hermetic sealing of the valve rod.

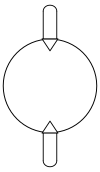

- Diaphragm and Rod Diaphragm Valves: Both diaphragm and rod diaphragm valves are widely used in the market. Valves with a continuous membrane are traditionally used in the pharmaceutical industry, rod diaphragm valves are mainly used in the food industry. In contrast to a hermetic seal with metal bellows, microbial contamination risks cannot be reliably and quickly detected under all circumstances.

field of use

UltraClean valve components are used for milk-based, lactic acid or ESL milk products . An acidic product environment or the constantly guaranteed cold chain can produce improved product quality with a likewise extended shelf life. Another important area of application is fruit juices and other fruit-based drinks. The pH value of the product to be manufactured serves as the basis for decision-making . If this is below the known limit of pH 4.5, the use of UltraClean component technology is recommended. In addition, water-based mixed drinks such as spritzers and mixed beer beverages are possible applications for UltraClean component technology. The growing sector of sports and wellness drinks as well as sauces and delicatessen foods are also suitable for this hygiene class. Of course, UltraClean valves can also be used as a component upgrade for classic hygienic processes such as in the brewing industry.

Aseptic

In the Aseptic hygiene class , everything revolves around commercial sterility and the endeavor to prevent any entry of germs after product sterilization under all circumstances. When talking about aseptic, the discussions essentially revolve around three areas: sterilizing the product, conveying and keeping the product sterile, and filling the product sterile. Aseptic processes stand for long-lasting and / or highly refined products that are often manufactured for special consumer groups. In addition to classic long-life milk products, medical nutrition and baby food are also classified in this hygiene class.

Product sterilization

The sterilization of a product can be achieved by various methods. In particular, combinations of processes are repeatedly examined which, in the sense of the “hurdle concept”, aim to reduce the overall treatment of the product with complete sterilization. Basically, the more valuable the product and the more heat-labile the food matrix, the more complex the technologies used, from sterilization and components to the filling machine .

Deliver and keep product sterile

So that a product can be kept sterile after it has been sterilized, the system must always be operated in a highly automated manner at a defined overpressure and properly cleaned and sterilized in-place. If the product is stored a second time before filling, the tank must also be covered with a sterile medium. Aseptic process components make a significant contribution to the aseptic operation of a system.

Sterile product filling

The sterile product filling is very diverse and can be defined or differentiated on the basis of various criteria. However, there are a few criteria that every aseptic filling machine must meet. The machine must be operated as a clean room with filtered air in the area of the filling valves and sterility must also be guaranteed by means of "laminar flow" against the container filling direction. On-place cleaning and sterilization round off the basic criteria in the filling area. In order to guarantee aseptic filling through to the end of the production chain, the container and closure must also be pre-sterilized into a commercially sterile product and kept sterile until it is hermetically sealed .

Requirements for the process components

Aseptic valves are characterized in particular by their uncompromising hermetic sealing of the valve stem and the minimization of the risk of contamination. In contrast to the lower hygiene classes, a hermetic seal of the product area from the environment (atmosphere) is essential for aseptic components. In addition, the contamination risks to be expected are lowest. In connection with the detection options, which are especially available with the metal bellows, this results in the highest rating. Aseptic valves in the system are subject to special requirements due to the regular sterilization cycles and the frequently changing temperatures.

The following valve concepts are traditionally used for "aseptic" processes

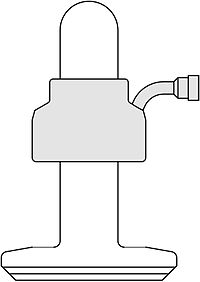

- PTFE bellows: Valves with PTFE bellows are known on the market. The main difference between PTFE and metal bellows is the detection option in the event of damage. In contrast to the metal bellows and similar to the diaphragm, deformation and / or partial damage to the bellows is more likely than a complete tear. In contrast to the membrane, however, this valve concept does not contain any dynamically loaded sealing points and the risk of bubble formation in the material is significantly reduced due to the manufacturing process.

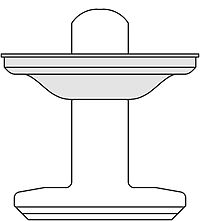

- Metal bellows: Aseptic valves with metal bellows represent the highest class of aseptic valves. On the one hand, this has to do with the material and the non-detachable connection of the bellows on both sides, but the option of bellows monitoring in the process is at least as important.

Overview of process components

The final division of the components into the hygiene classes is in any case subject to a further discussion on the basis of the requirement profiles and feature weightings known only to the user. In addition to the factors already mentioned, the influence on the follow-up costs including the maintenance and control expenses to be performed must be taken into account in order to be able to continuously guarantee secure production. As in all other areas of an installation, it is also important to assess which valve concept is best suited for the given conditions for the process components. From this point of view, there are partially flowing transitions between the hygiene classes described, which are ultimately to be assessed solely by the system operator and the person responsible for the product.

See also

Individual evidence

- ↑ Heribert Cypionka: Fundamentals of Microbiology, 3rd edition, Springer-Verlag, Heidelberg et al. O. 2006, ISBN 3-540-24084-5

- ↑ Johannes Krämer: Food microbiology. 6th edition. UTB, Stuttgart 2011, ISBN 3-8252-3607-2 , HG Kessler: Food and bioprocess engineering, dairy technology, 4th edition, Verlag A. Kessler, Munich 1996, ISBN 3-9802378-4-2

- ↑ Werner Baltes, Reinhard Matissek: Lebensmittelchemie (Springer textbook), 7th edition, Springer, August 2011, ISBN 3-642-16538-9

- ↑ Horst-Dieter Tscheuschner: Grundzüge der Lebensmitteltechnik, 3rd edition, Behr's Verlag, 2004, ISBN 978-3-89947-085-7

- ↑ Klaus Pichhardt: Food microbiology: Basics for practice, 4th edition, Springer, Berlin Heidelberg, ISBN 978-3-642-80472-4

- ↑ Rudolf Heiss: Food technology: Biotechnological, chemical, mechanical and thermal processes in food processing, 6th edition, Springer, August 2003, ISBN 3-540-00476-9

- ↑ Romeo T. Toledo: Process engineering principles of food production, 1st edition, Behr's Verlag, 2004, ISBN 978-3-86022-975-0

- ↑ Rudolf Heiss, Karl Eichner: Preservation of food: Chemical, physical and microbiological foundations of quality maintenance, 4th edition. Springer, June 2002, ISBN 3-540-43137-3