Ultrasonic flow meter

Ultrasonic flow meters (USD or UDM) measure the speed of a flowing medium (gas, liquid) with the help of acoustic waves. According to the basic DIN standard 1319, this flow measuring device consists of two parts: the actual measuring sensor ( ultrasonic sensor ) and an evaluation and supply part (transmitter or measuring transducer).

Acoustic flow measurement offers several advantages over other measurement methods. The measurement is largely independent of the properties of the media used, such as electrical conductivity , density , temperature and viscosity . The lack of moving mechanical parts reduces maintenance costs and there is no pressure loss due to a narrowing of the cross-section. A large measuring range is one of the other positive properties of this method. Two essential measuring principles are used in industrial systems for acoustic flow measurement using ultrasound: the ultrasonic Doppler method and the ultrasonic transit time method. The measuring methods of the ultrasonic flow measurement can be divided into the following four different measuring principles:

Doppler method

With the Doppler ultrasound measurement, the frequency shift of the emitted signal is recorded due to the flow velocity of the (inhomogeneous) particles in the medium. For this purpose, reflection points (pollution, air bubbles) are required in the medium. In partially filled pipes, the fill level must be determined in addition to the flow velocity in order to be able to calculate the flow.

Stroboscopic procedure

The stroboscope measurement process is similar to the Doppler process with reflected sound signals from moving particles. In contrast to the Doppler method, the frequency shift of the sound signal is not evaluated, but the time it takes for a particle to travel a defined distance in a sound cone is measured. The ultrasonic impulses are emitted one after the other in short and rapid succession (similar to stroboscopic recordings with light).

Drift method

In the so-called drift method, a continuous ultrasonic signal is emitted perpendicular to the flow of the medium to be measured. The intensity distribution is deflected by the medium according to the direction of flow. The relative flow velocity can be determined from the relative intensity distribution of the ultrasonic signal on the opposite receivers.

Transit time difference measurement

For this measuring method, the medium must be as homogeneous as possible and only have a low solid content.

To put it simply, we consider two boats that cross a river diagonally on the same line, one in the direction of flow and the other in the opposite direction. The boat, which is moving in the direction of the current, needs a much shorter time to reach the opposite bank. The ultrasonic waves behave in exactly the same way. A sound wave propagates faster in the flow direction of the measuring medium than the sound wave in the opposite direction.

The running times are measured continuously. The difference in transit time of the two ultrasonic waves is therefore directly proportional to the mean flow velocity. The flow volume per unit of time is the result of the average flow velocity multiplied by the respective pipe cross-section of the sensor.

The identification of a medium can also be determined directly by measuring the transit time of ultrasonic waves. The sound propagation time in water, for example, is shorter than in heating oil.

Calculation bases

The flow velocity is calculated using the transit time method using the following equation:

Here are:

- v - mean flow velocity of the medium

- t 1 - transit time of the ultrasonic signal with the flow

- t 2 - transit time of the ultrasonic signal against the flow

- L - length of the ultrasonic path

- α - angle of the ultrasonic signal to the flow

Data acquisition

In modern evaluation devices, the sound transit times and the transit time differences are now determined with digital signal processors (DSP). Common methods are the first-negative edge evaluations and the cross-correlation method .

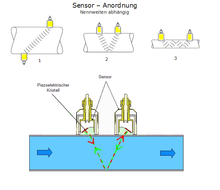

Multi-channel process

The evaluation electronics are mostly operated in a multi-channel process, which can therefore reliably and precisely record the actual flow conditions even under difficult conditions.

Multi-channel principle

An ultrasonic flow meter measures the flow rate in the measuring tube by means of two opposing sensor arrangements. These are arranged at an angle so that one sensor is mounted a little further downstream than the other. The flow signal is determined by alternately measuring the transit time of an acoustic signal from one sensor to the other, using the effect that sound is transmitted faster with the flow direction than against the flow direction. The volume flow is determined by sequential measurement between all sensor pairs in the arrangement. This arrangement ensures that after typical flow restrictions, such as a pipe bend in one or two levels, only a short straight pipe run in front of the measuring device is required. The digital signal processing guarantees the constant evaluation of the flow measurement and reduces the sensitivity with regard to multiphase flow conditions and thus increases the reliability of the measurement considerably.

Clamp-on flow meter

As a special form of ultrasonic flow measurement, there is a measuring arrangement that is attached to the outside of the pipe, does not require any intervention in the pipe itself, and thus the amount or the flow rate can be determined. Application range from nominal diameters DN 5 to DN 6000. This clamp-on method is a cost-effective solution, especially for large nominal diameters.

The main advantages of clamp-on:

- can be used for all homogeneous media in sound-permeable pipes, also with lining;

- Chemical or process applications;

- Large medium temperature range −160 ° C to +600 ° C

- ideal for retrofitting;

- Installation without process interruption.

- Special clamp-on flow meters are also available for measuring gases

Clamp-on probes are also available for flow measurement on hoses. This method is also non-invasive and can optionally be combined with bladder detection . In order to achieve optimal measurement accuracy, the probe is usually calibrated to the specific hose material. These clamp-on probes are mainly used in the medical field. For example, when using the heart-lung machine , which takes on the function of heart and lungs during open heart surgery, the exact blood flow in the tube system of the extracorporeal circuit is determined. Even with the ECMO ( extracorporeal membrane oxygenation ) application , the blood flow is monitored by default with a clamp-on sensor, usually in combination with bubble detection.

In-line flow meter

In-line measuring sections

This type of ultrasonic flow meter is built into the pipeline. The devices can be calibrated in the factory and therefore achieve a significantly higher level of accuracy, which can also be achieved in the field. With a multi-path sensor arrangement, the accuracy can be increased further and the influence of an asymmetrical flow profile can be minimized.

The sensors are suitable for numerous tasks in process control and supply applications in almost all industrial sectors. The advantages of the inline version are:

- calibrated flow measurement for conductive and non-conductive liquids, such as solvents and hydrocarbons;

- Diagnostic capability and data backup for increased process quality;

- permanent self-monitoring of transmitter and sensor;

- lower requirements for upstream pipelines for the design with four jets only inlet sections (pipe diameter ≤ 5) required;

- no pressure loss;

- maintenance-free, no moving parts.

Typical applications are in the field of water and wastewater, energy and heat and in the field of chemistry.

In-line installation measurements

In addition to the design of the in-line measuring sections, there are also in-line installation measurements in which the sensors are installed in existing pipelines. The advantages here are that the measurements can be retrofitted and can be easily maintained. Such measurements are particularly suitable for larger pipelines, since in-line measuring sections then become difficult to manufacture and untransportable. It can also be used in open channels, canals and rivers; the ultrasonic transducers are then mounted on the channel wall.

Applications

- Turbine acceptance measurements in hydropower plants according to IEC 60041 or ASME PTC 18

- Pipe burst monitoring at storage power plants

- Cooling water measurements in thermal power plants

- Inflow and outflow measurements in sewage treatment plants according to EKVo

- Hydrological monitoring and tidal wave forecasting in rivers and streams

- Monitoring of irrigation channels

Flow meter for open channels and partially filled pipes

In addition to the above-described ultrasonic flow meters for filled lines, there are also those for partially filled lines and open channels. These also work according to the runtime principle with one or more horizontal measuring paths. For such applications, the ultrasonic speed measurement is usually combined with a level or fill level meter and an evaluation unit that calculates the cross-section through which the air flows. The evaluation unit then calculates the flow rate from the mean flow velocity and the cross-section through which the water flows.

Norms

Flow measurement in open channels is described in ISO 6416. Known methods for calculating the flow are the mid-section and the mean-section method.

Applications

- Inflow of hydropower plants

- Water hydrology / tidal wave monitoring in rivers and streams

- Urban hydrology / sewer network investigations

- Discharge of wastewater to rivers

- Cooling water withdrawal from power plants

advantages

- precise measurement possible over wide spans;

- Display of flow in operating units;

- insensitive to pressure and flow shocks, vibrations; Dirt particles in the gas flow;

- suitable for custody transfer;

- High-temperature versions up to medium temperatures of 500 degrees Celsius, depending on the manufacturer and design

disadvantage

Sound waves are pressure waves that generate mechanical waves due to the compressibility of the medium. Extremely high viscosity dampens this movement and thus the propagation of the sound waves. Therefore there are limits to the viscosity. As a rule, this limit is far above the values that occur in practice; it only plays a role in a very small number of individual cases. High proportions of gas lead to increased compressibility of the medium and to an extremely low speed of sound. Both effects can lead to the failure of the measurement.

Not all media can be measured:

- Gas bubbles: reflections / attenuation, max .: 1% by volume

- Solid particles (reflections) Guide value: <5% by volume

- Viscosity (damping) Guide value: max. 100 cP / DN [m]

Individual evidence

- ↑ DIN 1319-1: 1995-01, Fundamentals of measurement technology - Part 1: Basic concepts, Beuth Verlag, Berlin.

literature

- Kaspers / Küfner measuring - controlling - regulating elements of automation technology ; Vieweg + Teubner Verlag; ISBN 3-8348-0006-6

- DIN EN ISO 6416, Hydrometry - Measurement of the discharge with the ultrasonic method, Beuth Verlag Berlin