Band filter (process engineering)

As a band filter in is mechanical filter technology a cleaning device called that as an essential component is a conveyor belt contains.

Band filter in mechanics

Belt filters are continuously operating horizontal filters that are used in mechanical solid-liquid separation. A distinction is made between belt and indexing belt filters that work with vacuum and gravity filters .

Belt filters are built in sizes from 1 m² to over 250 m² filter surface. They are characterized by good filter performance, effective washing options for the solids and easy cleanability of the filter medium. Belt filters are well suited for the separation of suspensions with 3 to 40% solids with particle sizes from 1 µm to 100 µm. The suspension temperature should not exceed 95 ° C. Due to their versatile applicability, they are used in the chemical industry, pharmaceuticals, the food industry, environmental technology, the paint and pigment and mineral industries and in mining.

Strap filter

A continuously revolving, elastic carrier belt is guided between two deflection rollers and forms a trough-shaped depression on the surface by means of lateral webs. An endless filter cloth runs synchronously in the trough and is returned to the underside via separate rollers. The suspension is evenly applied at the beginning of the belt. The filtrate flows through the filter cloth due to gravity or it is sucked through the filter cloth by an applied vacuum and then discharged. The solid remains on the filter cloth and forms the filter cake . At the end of the belt, the filter cloth separates from the carrying belt at the rear deflection roller. The shoulder belt runs back to the front deflection roller. The filter cloth is transported to another roller, where it is deflected and the filter cake is thrown off. The filter cloth is then washed and returned.

Intense deformation of the carrying belt occurs at the deflection rollers. Therefore, the shoulder strap must be made of permanently elastic material with sufficient tensile strength . In addition, it should be sufficiently chemically and , if necessary, also thermally resistant. Carrying straps used to be made of rubber , but now more durable, easier-to-clean materials are used. The filter cloth must also be resistant to the prevailing chemical and thermal conditions. In addition, the filtration properties and mechanical stability must not change during use. Carrying belt filters achieve very high solids capacities and are particularly suitable for the filtration of suspensions with coarse-grained substances.

Timing band filter

A rotating textile belt, which is moved cyclically (or continuously, see below oscillating vacuum cups), serves as the filter medium . The suspension is evenly applied to the belt, the filtrate is suctioned off downwards, the resulting filter cake remains on the upper side of the belt and can then be washed, extracted , dehumidified, mechanically compressed or thermally dehumidified on the filter . At the end of the filter, the filter cloth is deflected on a roller and the filter cake is thrown off. After the cake has been removed, the filter cloth is cleaned. The filter cloth is rinsed from the cake side, the back or from both sides.

Indexed belt filters are made of metal, stainless steel or plastic , depending on the application . They can be designed in an open frame design, with a cover as protection against dust and in a gas- or pressure-tight box design. This means that different applications can be covered: From the mineral industry with coarse-grained and abrasive products to the dye industry with very fine particles to the food and pharmaceutical industry with GMP requirements ( Good Manufacturing Practice ) and sterile atmosphere.

A distinction is made between indexing belt filters with stationary vacuum trays and clockwise movement of the belt and indexing belt filters with oscillating vacuum trays and continuous movement of the belt.

With stationary vacuum trays

Several vacuum dishes, usually of the same size, lie one behind the other on the filter frame and are firmly connected to the vacuum and filtrate system. During the work cycle, there is a vacuum, the filter cloth stands still and is fixed by the vacuum and the weight of the filter cake on the support grid of the stationary vacuum tray below. The vacuum is then interrupted with shut-off devices that open and close quickly and the vacuum trays are ventilated with ambient pressure. This releases the filter cloth and can be transported further. The length of the belt transport per interval corresponds to the zone length of a vacuum tray. The filter cake is ejected from the take-off roller. As soon as the filter cloth has been transported to the new zone, vacuum is applied again and the next work cycle begins. The cloth cleaning takes place during the belt return transport.

With oscillating vacuum cups

In this process, the vacuum trays are designed to be movable. Due to the vacuum and the weight of the filter cake, they are fixed to the filter cloth above and move synchronously with it in the direction of cake removal. The oscillating vacuum cups are connected to the vacuum system via elastic filtrate drainage hoses. A new variant manages without elastic hoses, it has a kind of linear control head on which the trays slide and which connects them to the static vacuum system. After the vacuum has been interrupted, a lifting cylinder periodically returns the vacuum cups to their original position, while the filter cloth is continuously transported onwards at a continuously variable speed. The filter cake is also thrown off and the filter cloth cleaned continuously. After reaching the starting position, the next work cycle begins.

Gravity filter

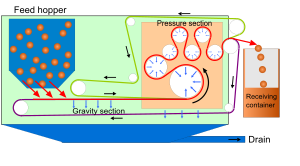

Gravity filters are used for the fully automatic, continuous cleaning of liquids, especially emulsions and oils from metalworking, with normal demands on the degree of purity. An endless metal belt runs between a drive and a deflection roller and serves as a carrier for the actual filter medium. The belt and the filter medium form a trough into which the suspension flows. Hydrostatic pressure builds up on the filter medium and the filtrate flows down through the filter medium. The solid is deposited on the filter medium.

The drive by means of a gear motor and thus the consumption of the filter medium is controlled by a float switch, depending on the level of contamination. The liquid level rises to a maximum level. If this is achieved, the float switch triggers a belt cycle. At the same time, used filter medium is conveyed into the dirt box and fresh one is drawn in. The filtrate is collected under the filter and conveyed on from there.

See also

Individual evidence

- ↑ English website for the description of band filters .

- ↑ Klaus Luckert, Luckert, Klaus: Manual of the mechanical solid-liquid separation. Vulkan-Verl, Essen 2004, ISBN 3-8027-2196-9 , p. 222 ff .