CIGS solar cell

The CIGS solar cell is a type of solar cell whose absorber consists of the material copper-indium-gallium-diselenide (CIGS). CIGS solar cells have, in contrast to crystalline silicon a solar cells absorber with a direct band gap , which is why the material has a higher absorption coefficient has light and substantially better absorbed . As a result, depending on the manufacturer, the CIGS absorber is only 1–2 µm thick and can be manufactured using thin-film technology, while thick-film solar cells based on silicon are at least approx. 150 µm thick. Due to the small thickness, it is possible to use significantly less semiconductor material.

Since the paths of the photo charge carriers between generation and collection are shorter due to the small layer thicknesses, absorber material with a shorter diffusion length of the minority charge carriers can be used than with crystalline silicon solar cells. Thin-film solar cells are therefore made from polycrystalline CIGS, which reduces the amount of energy required and the costs compared to the production of monocrystalline silicon. Due to the small layer thicknesses, light and even flexible solar modules for applications in the field of photovoltaics can also be produced with the appropriate substrate selection . Furthermore, modules can be manufactured directly in a production line - without the detour via individual solar cells that are then connected.

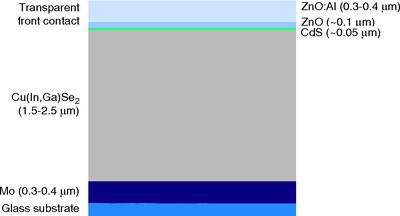

construction

The graphic shows a schematic cross section of a Cu (In, Ga) Se 2 solar cell with the corresponding layer thicknesses. Even if flexible substrates offer advantages, up to now glass has mostly been used as a substrate. The substrate is coated with molybdenum (Mo), which serves as a back contact.

The eponymous semiconductor Cu (In, Ga) Se 2 is also referred to as an absorber, since a large part of the incident light is absorbed here. It is lightly p-doped due to intrinsic defects in the material. As an n-doped layer, zinc oxide (ZnO ) is heavily doped with aluminum (Al). This layer, also known as aluminum-zinc oxide (AZO), forms a transparent conductive oxide layer (TCO). Due to the very high band gap of the zinc oxide ( E g, ZnO = 3.2 eV), this layer is permeable to visible light. Hence it is also called a window. There are buffer layers made of cadmium sulfide (CdS) and undoped ZnO between the window and the absorber . Because of the toxicity of cadmium sulfide and the hope for electricity gains, research is also concerned with alternative buffer materials ( In 2 S 3 , Zn (O, S), (Zn, Mg) O and others). The pn junction is a heterojunction, that is, the p- and n-doped layers consist of different semiconductors. The asymmetrical doping of the layers results in an asymmetrical space charge zone which extends deeper into the absorber than into the ZnO.

During the Mo and ZnO-layers by sputter deposition are prepared and CdS mostly in a deposited chemical bath (engl. Chemical bath deposition , CBD) is, there are several variants to produce the absorber. Most common are the simultaneous thermal evaporation of the elements or the deposition of the metals (Cu, In, Ga) by electroplating , sputter deposition or other processes with subsequent heating in a selenium atmosphere.

Efficiencies

The efficiency record for a CIGS solar module was set in autumn 2015 by the company tsmc solar and is 16.5% based on the module area (as of Feb. 2016). With small laboratory cells, higher efficiencies are achieved, which have been increased continuously and at ever shorter intervals:

- At 20.1% (at 0.5 cm²), the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) in April 2010 achieved the highest value for thin-film solar cells worldwide . Previously, the US research institute NREL had achieved the highest level of efficiency for 16 years.

- At the Eidgenössische Materialprüfungs- und Forschungsanstalt in January 2013, this value was exceeded by a CIGS solar cell on plastic film with 20.4%.

- In October 2013, the ZSW increased it to 20.8%, which is higher than the efficiency of crystalline solar cells.

- In December 2015, Solar Frontier published a record of 22.3%.

- In June 2016, the ZSW was able to report that it had set a new world record with 22.6%.

- In December 2017, Solar Frontier published a new record efficiency of 22.9%.

- On January 17, 2019, Solar Frontier published a new record efficiency of 23.35%.

- On December 4th, 2019 the company NICE Solar Energy published a new record efficiency of 17.6% on a module measuring 120cm * 60cm (total area 0.72m²). The new efficiency record was confirmed by TÜV Rheinland.

- In spring 2020, the speedCIGS research project achieved a new record efficiency of 24.3%.

advantages and disadvantages

Due to the low layer thickness, less semiconductor material is consumed and, with a corresponding number of units, more cost-effective production is expected than with thick-film technology. The energy payback time for thin-film solar cells is also shorter than for thick-film solar cells. There could be restrictions in the mass production of CIGS modules because the raw material indium is relatively scarce and is also used in other technological products based on semiconductors (e.g. flat screens ). Today indium is a by-product in tin production, but it could also be mined directly in the future. Because of the thin-film technology, however, only very small amounts of indium are required for the production of solar cells. Compared to crystalline solar cells, the disposal of CIGS solar cells that contain Cd is significantly more complex at the end of their life because the material mixture is toxic. In addition, larger amounts of toxic compounds are released in the event of a fire if the solar cell contains Cd. While CIGS solar cells with a CdS buffer layer are still the standard in laboratories, industrial CIGS solar cells are often manufactured without a CdS buffer layer and an alternative front-side contact.

Manufacturer

As in the rest of photovoltaics, the manufacturers of CIGS modules are also subject to strong fluctuation. In recent years, many manufacturers have given up (e.g. CIS Solartechnik, Heliovolt, Nanosolar, Soltecture, Solyndra, tsmc-solar). On the other hand, new companies have appeared. Large manufacturers are among others (as of Feb. 2016):

- Avancis GmbH (DEU) (subsidiary of the Chinese construction group CNBM )

- Global Solar (USA) (part of the Chinese energy supplier Hanergy )

- NICE Solar Energy GmbH (international research joint venture) (formerly Manz CIGS Technology GmbH, previously Würth Solar)

- MiaSolé (USA) (part of the Chinese energy supplier Hanergy )

- Solar Frontier KK (JPN) (largest CIGS manufacturer with more than 1000 MWp annual capacity, does not use heavy metals such as cadmium Cd or lead Pb)

- Solibro (SWE) (part of the Chinese energy supplier Hanergy )

- Solo power (USA)

- Stion (USA)

- Flisom (Switzerland)

Flexible CIGS solar cells

In addition to the deposition on glass substrates, work is being carried out on the market launch of flexible CIGS solar cells and modules. In addition to metal foils , high-temperature polymers such as polyimide are also used as substrates . In the EMPA laboratory in Switzerland, efficiency levels of 18.7% were already achieved on polyimide film in 2011 and 20.4% in 2013. To transfer this technology into mass production, various companies have set up pilot production systems and in 2009 they achieved efficiencies of up to 13.4%.

Individual evidence

- ↑ TSMC Solar Commercial-size Modules (1.09m2) Set CIGS 16.5% Efficiency Record (press release)

- ↑ http://www.zsw-bw.de/index.php?id=111

- ↑ http://www.empa.ch/web/s604/weltrekord

- ↑ ZSW: ZSW produces CIGS record cells ( Memento of the original from February 4, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Press release from October 23, 2013.

- ↑ Solar Frontier press release: http://solar-frontier.com/eng/news/2015/C051171.html

- ↑ ZSW sets a new world record for thin-film solar cells. In: www.zsw-bw.de. Retrieved June 16, 2016 .

- ↑ 2017. Retrieved February 3, 2018 .

- ↑ Solar Frontier Achieves World Record Thin-Film Solar Cell Efficiency of 23.35%. Solar Frontier KK, January 17, 2019, accessed June 18, 2019 .

- ↑ Manz joint venture Nice Solar Energy reports an efficiency record of 17.6 percent for CIGS modules. December 4, 2019, accessed on February 26, 2020 (German).

- ↑ Another world record for the speedCIGS research project. Retrieved July 13, 2020 .

- ↑ Rolf Frischknecht, René Itten, Parikhit Sinha, Mariska de Wild-Scholten, Jia Zhang: Life Cycle Inventories and Life Cycle Assessments of Photovoltaic Systems . Ed .: IEA International Energy Agency, IEA PVPS Task 12, Subtask 2.0. LCA Report IEA-PVPS, T12-04: 2015, 2015, ISBN 978-3-906042-28-2 .

- ^ Björn A. Andersson: Materials availability for large-scale thin-film photovoltaics . In: Progress in Photovoltaics: Research and Applications . tape 8 , no. 1 , 2000, pp. 61-76 , doi : 10.1002 / (SICI) 1099-159X (200001/02) 8: 1% 3C61 :: AID-PIP301% 3E3.0.CO; 2-6 .

- ↑ Amy C. Tolcin: Mineral Commodity Summaries - Indium. (PDF) In: US Geological Survey. USGS, January 2009, accessed March 27, 2017 .

- ↑ https://www.greentechmedia.com/articles/read/TSMC-Shutting-Down-CIGS-Thin-Film-Solar-Manufacturing

- ↑ http://solar-frontier.com/eng/company/index.html

- ^ Solar Frontier, Technology, Ecology. Solar Frontier, accessed March 27, 2017 .

- ↑ Swiss researchers boost efficiency of flexible solar cells to new world record: Record efficiency of 18.7% for flexible CIGS solar cells on plastics. empa.ch, May 19, 2011, accessed on July 4, 2012 .

- ↑ Empa degrees of efficiency in 2013

- ↑ Solarion AG (Ed.): World record: 13.4 percent efficiency for solar cells on plastic film ( Memento of the original from January 2, 2014 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 144 kB). (Press release of October 7, 2009)