Differential thread

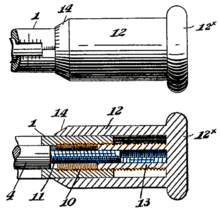

Differential thread (also differential thread) describes the combination of two ordinary threads with different pitches that are located on a common axis . When this axis rotates, the components seated on the two threads move relative to one another, which corresponds to the difference in the gradients. This enables a very precise setting of the distance between the two components, which would otherwise only be possible with a very fine thread that would have a correspondingly low mechanical stability.

A screw with a differential thread also enables space-saving and firm clamping of components. The screw has - in different areas of its shaft - two threads with the same thread direction but different pitch P. The thread diameter can also be freely selected. When the components are braced against each other, the screw with a differential thread acts like a normal screw, the thread pitch of which is the difference between the two pitches - that is, relatively small.

The smaller the pitch difference (with the same tightening torque ), the greater the clamping forces.

Similarly, nuts with differential threads can also be designed.

Applications

- Tool holder of indexable inserts (lathe)

- Rarely on connecting rods in reciprocating engines if the lower connecting rod eye is split

- Clamping screw on Morse taper tool holders (e.g. Wabeco)

See also

see also: thread (for the terms: pitch or thread direction)