Printing unit

The term printing unit describes an assembly of the printing machine . In offset printing , it consists of the plate, rubber and impression cylinders, as well as the inking and dampening system . In addition, printing units can be equipped with washing devices and automatic systems for loading plates.

Printing principle

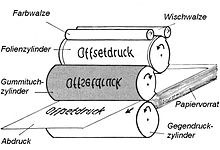

The sheet-fed and web offset printing work according to the same pressure principle. The printing plate is located on the plate cylinder, around which the dampening and inking units are grouped. With each cylinder revolution, the printing plate is moistened and then colored with printing ink . The ink adhering to the printing plate is transferred to the rubber blanket of the rubber cylinder and from there to the substrate with each cylinder revolution . In sheet-fed offset presses, the required counter pressure is provided by an impression cylinder. Two printing units can also work against a common impression cylinder. In web offset printing, the paper web in each printing unit is passed between the blanket cylinders of two printing units. These transfer the printing ink and at the same time generate the necessary counter pressure.

Dampening and inking unit

With a system of numerous rollers, the inking unit in sheet-fed offset presses has the task of splitting the printing ink into an even, thin film of ink and transferring it to the printing plate. The color guidance parallel to the cylinder axis can be influenced by zone-by-zone color presetting, which is done with so-called zone screws. A considerable reduction in set-up times is achieved with automatic presetting systems. Before the ink is applied, the dampening unit must moisten the printing plate with dampening solution so that the non-printing parts of the printing form do not accept any ink. The addition of alcohol reduces the surface tension of the fountain solution. With waterless offset printing , no dampening unit is required and is therefore switched off. The printing unit is equipped with a cooling device here.

Designs

The in-line design has established itself in sheet-fed offset printing machines. The printing units are arranged one behind the other, so that there are eight printing units one behind the other for an 8-color machine for perfecting .

In web offset presses, the arrangement of the cylinders within the printing unit is highly variable. Due to the modular design, manufacturers can put together a machine in a modular system . The most important printing unit constructions in web offset printing include the most frequently used three-cylinder system on small-format machines for printing continuous forms and labels. The four-cylinder system , developed by the inventor Caspar Hermann in 1907 , is mainly used for commercial printing . The nine-cylinder system , also known as a satellite , is primarily used in newspaper printing . The so-called eight - high tower is also used for newspaper printing. These are two horizontal four-cylinder printing units , also called H printing units , one above the other.

Individual proof

- ↑ Helmut Kipphan (Ed.): Handbuch der Printmedien, p. 247 f. Verlag Springer, November 2000. ISBN 3-540-66941-8

literature

- Manfred Aul: Textbook and workbook pressure. Verlag Beruf und Schule, Itzehoe 2007. ISBN 978-3880136403

- Helmut Kipphan (Hrsg.): Handbook of Print Media: Technologies and Production Processes. Springer-Verlag, Berlin, November 2000. ISBN 3-540-66941-8

- Wolfgang Walenski: The web offset printing. History. Modern technology. Materials. Fachschriften-Verlag, Fellbach 1995. ISBN 978-3931436018