Filler wire

|

|

DIN EN ISO 17632 |

|---|---|

| Area | welding |

| title | Welding consumables - cored wire electrodes for metal arc welding with and without shielding gas of unalloyed steels and fine-grain steels - classification |

| Brief description: | Cored wire electrodes |

| Latest edition | 2008-08 |

| ISO | 17632 |

Flux-cored wire (also core wire ; English : flux-cored wire ) is a filled tube wire . In semi-mechanical arc welding, it is continuously fed into the weld pool via a feed motor at a variable speed; there are special flux-cored wire welding devices available in stores for this purpose.

For the cored wire welding process, see main article welding

The wire is produced by cold forming a flat strip , which is used as a sheathing material. At one of the production stations, the powdery filling is introduced into the U-shaped bent belt. At further stations, the belt is closed and the final dimension is calibrated.

At the beginning of the 1920s there was still no welding technology in the modern sense. The iron and steel parts, which are then usually autogenous put together with bare wires, met today's requirements in strength properties and welding performance in any way.

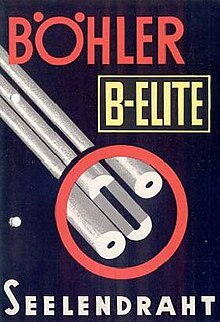

The core wire invented by Franz Leitner , the boss of the steelworks founded by Albert Böhler , which later became the Böhler-Uddeholm company , in 1927 brought the breakthrough in welding technology. According to the cored wire principle known today, there was a flux inside a steel jacket that had a positive and stabilizing effect on the welding properties in the arc.

standardization

Cored wire electrodes are standardized in EN ISO 17632 welding consumables - cored wire electrodes for metal arc welding with and without shielding gas of unalloyed steels and fine-grain steels - classification .